Performance simulation calculation method for screw compressor

A screw compressor, simulation calculation technology, applied in the field of simulation analysis, can solve problems such as the inability to meet the performance prediction of large-scale variable working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

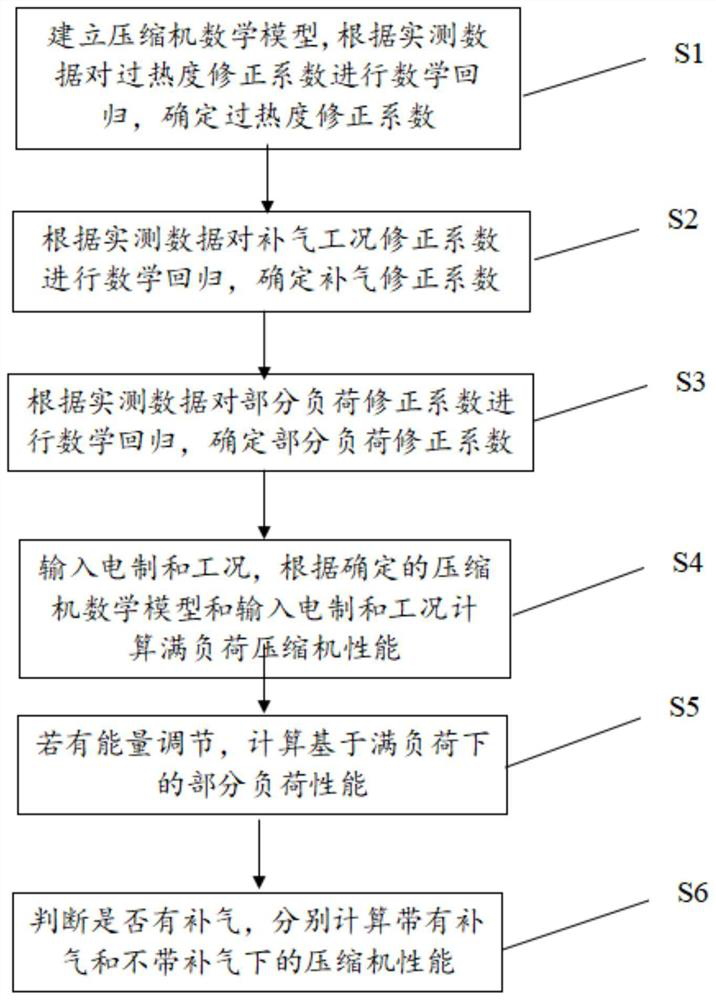

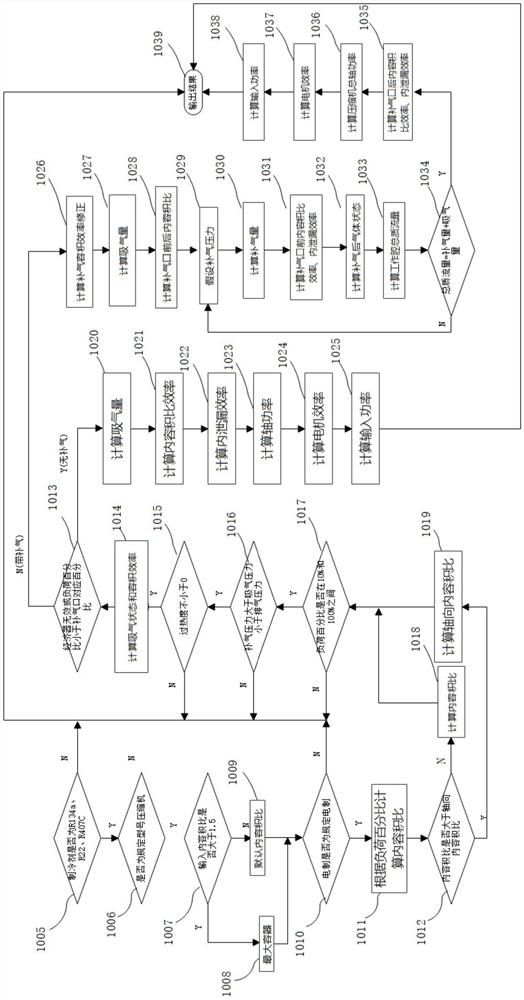

[0073] Please refer to figure 1 and figure 2 , a screw compressor performance simulation calculation method, comprising the following steps:

[0074] Step S1: Establish a mathematical model of the compressor: extract the correction coefficient related to the working condition, perform mathematical regression on the correction coefficient according to the actual measurement results, determine the full load calculation model, perform mathematical regression on the superheat correction coefficient according to the actual measurement data, and determine the superheat correction coefficient;

[0075] In addition, other performance-related influencing factors and corresponding correction factors are determined. Other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com