A single-unit two-stage variable-frequency screw compressor with adjustable internal volume ratio

A screw compressor, screw compression technology, applied in the direction of machine/engine, mechanical equipment, liquid fuel engine, etc., can solve the problems of low compressor efficiency, poor economy, fluctuation, etc., to improve performance, improve compressor efficiency, the effect of reducing additional compression losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

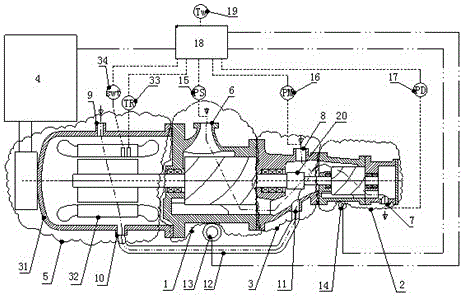

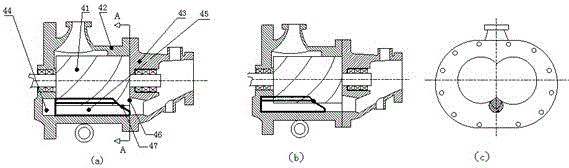

[0037] like figure 1 , 2 As shown, the single-unit two-stage variable-frequency screw compressor with adjustable internal volume ratio includes a low-pressure stage screw compression part 1, a high-pressure stage screw compression part 2, an intermediate pressure part 3, a frequency converter 4, a drive motor part 5, and a drive device ( Low pressure stage drive device 13 and high pressure stage drive device 14), control mechanism 18 and pressure sensor and temperature sensor 19. The suction port 6 of the compressor is located on the suction side casing of the low-pressure stage screw compression part 1 ; the exhaust port 7 of the compressor is located on the discharge side casing of the high-pressure stage screw compression part 2 . Both the low-pressure stage screw compression part 1 and the high-pressure stage screw compression part 2 include a pair of female and male rotors. The motor rotor shaft of the driving motor part 5 is coaxially arranged with the male rotor suct...

Embodiment 2

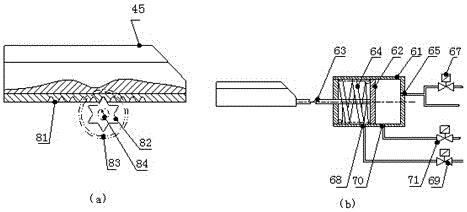

[0047] The single-unit two-stage variable-frequency screw compressor with adjustable internal volume ratio described in this embodiment is basically the same as that in Embodiment 1, the difference is that the drive device of the internal volume ratio regulating valve 45 is driven by an oil piston pull rod, and its Structural diagram such as image 3 (b) shown.

[0048]The drive device is suitable for the adjustment of the internal volume ratio in sections (the figure shows 3-stage adjustment, that is, the maximum, middle, and minimum internal volume ratios). The oil piston 62 divides the oil cylinder 61 into a spring chamber and an oil injection chamber with a built-in spring 64 under pressure. The oil piston 62 is connected with the internal volume ratio regulating valve 45 through a pull rod 63 . An oil hole 65 is arranged on the opposite outer end surface of the oil piston 62 of the oil injection chamber and communicates with the external oil passage. The high-pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com