Simulation method of impact mechanical properties of carbon fiber composites based on multi-scale

A composite material and simulation method technology, applied in design optimization/simulation, instrumentation, geometric CAD, etc., can solve problems such as high time cost, large amount of calculation, and failure to distinguish the difference between fiber and matrix strength, so as to reduce simulation time, The effect of reducing design and development costs and shortening the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] The present invention will be further described in detail below with reference to the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

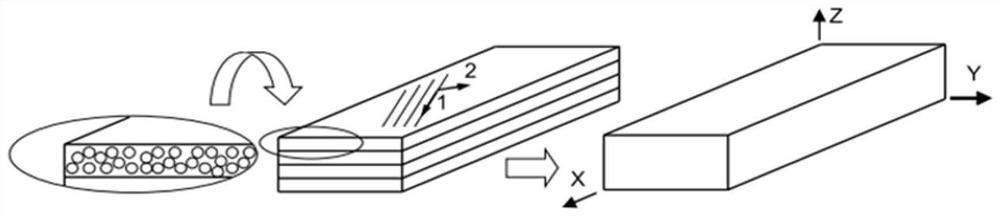

[0096] like figure 1 As shown in -20, the present invention provides a multi-scale-based simulation method for the impact resistance mechanical properties of carbon fiber composite materials, including:

[0097] Step 1. Carry out CFRP quasi-static test to obtain parameters;

[0098] Step 2: Carry out the drop weight impact test under different working conditions to obtain the dynamic mechanical response and damage form of the CFRP;

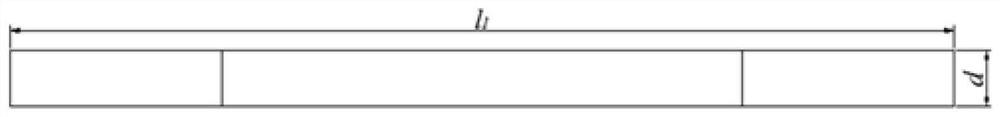

[0099] Step 3: Establish a CFRP scale model, set boundary conditions, and analyze the influence of meso-parameters;

[0100] Step 4: Calculate the magnification factor, establish the relationship between the microscopic and the macroscopic, reconstruct the material constitutive, and update the macroscopic stiffness matrix;

[0101] Step 5. Carry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com