A Finite Element Calculation Method of Misalignment of Bevel Gears Considering the Effects of Multiple Factors

A calculation method and finite element technology, applied in calculation, special data processing applications, instruments, etc., can solve problems such as large amount of calculation, deformation, complex modeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

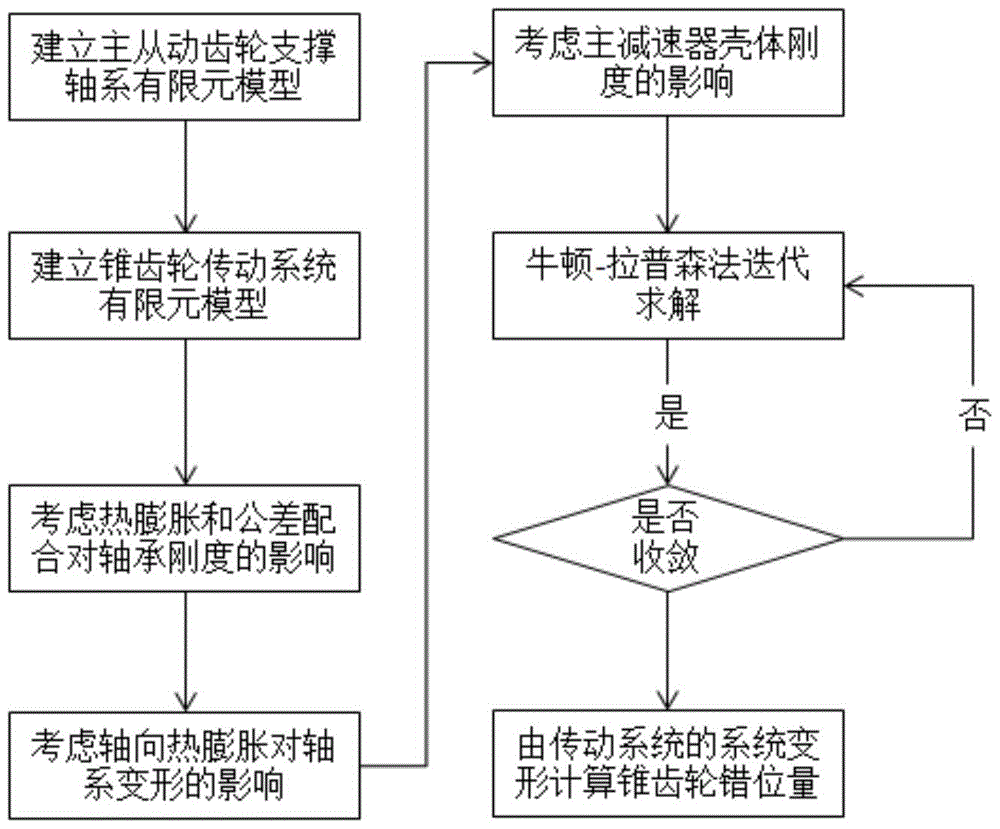

[0077] Such as figure 1 As shown, a finite element calculation method of bevel gear misalignment considering the influence of multiple factors includes the following steps:

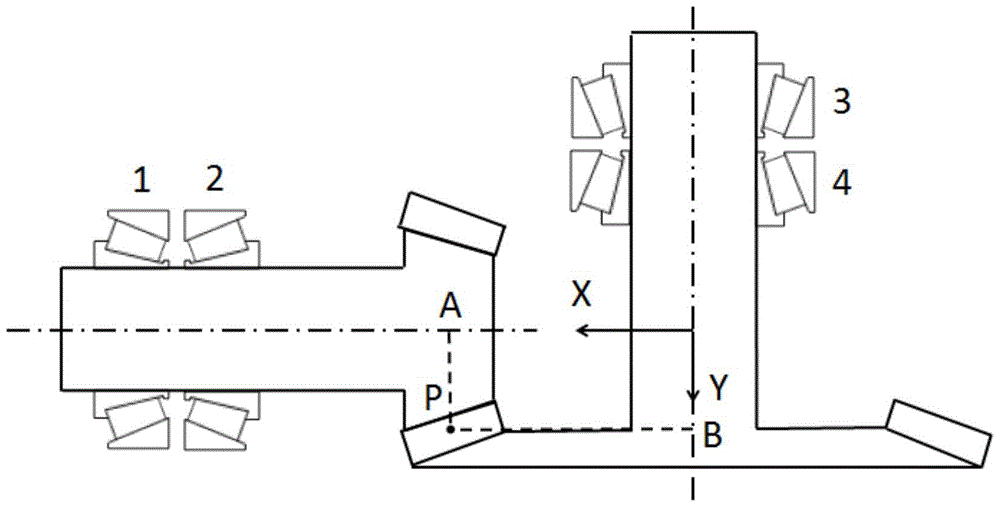

[0078] 1) Establish the finite element model of the supporting shaft system of the main and driven gears composed of the gear shaft and the bearing respectively: simulate the bearing by establishing the bearing unit considering the coupling and nonlinearity of the bearing stiffness, and establish the Euler model considering the shear deformation The beam element simulates the gear shaft, and obtains the finite element model and stiffness matrix of the supporting shaft system of the driving gear and the driven gear respectively.

[0079] In this embodiment, the bearing unit has two nodes, which respectively represent the inner and outer rings of the bearing, and the positions of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com