Fluid permeance surface layer of body fluid absorption article, and method of producing same

A manufacturing method, surface layer technology, applied in the direction of absorbent pads, fabrics, medical science, etc., can solve problems such as skin irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

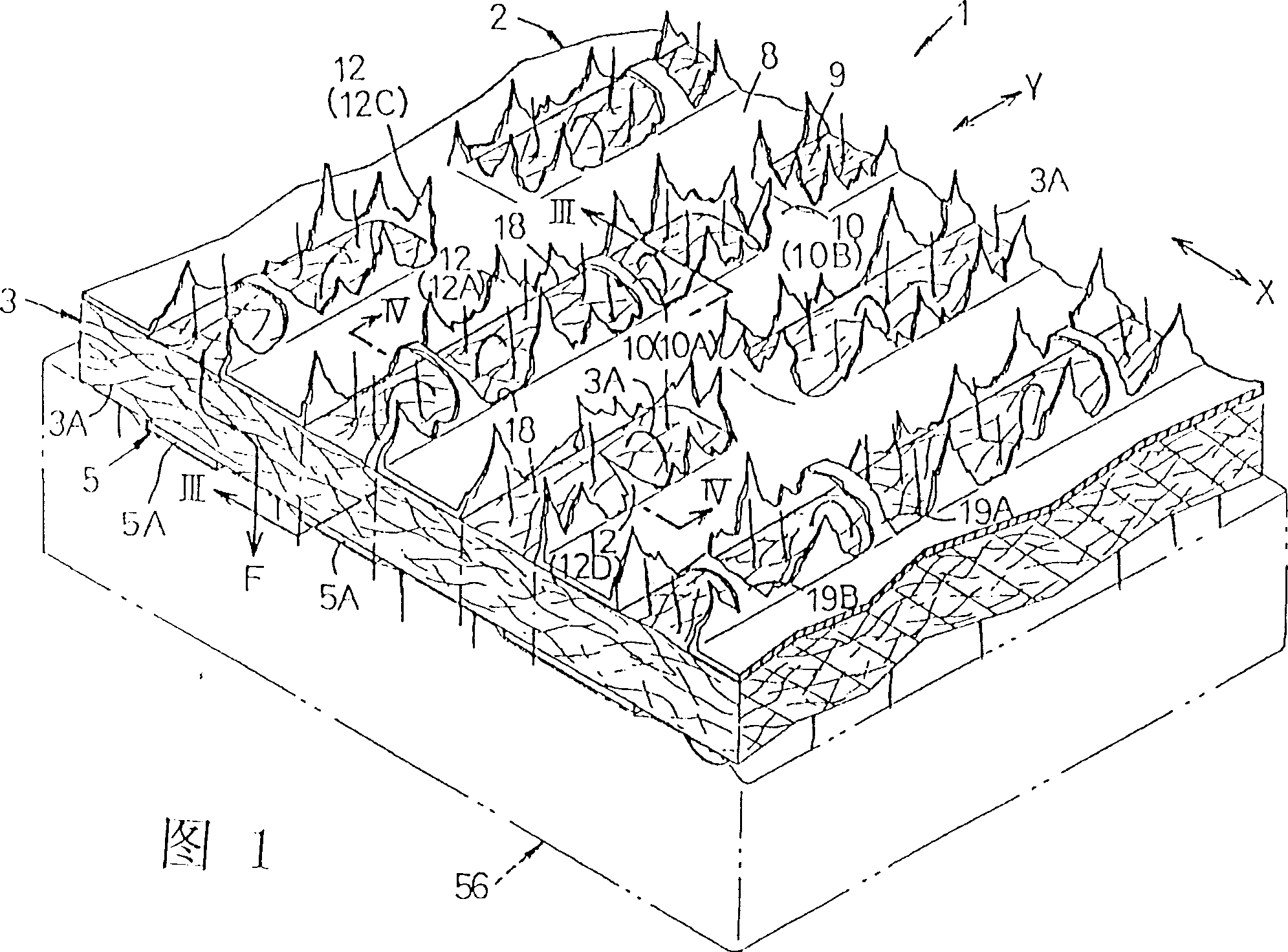

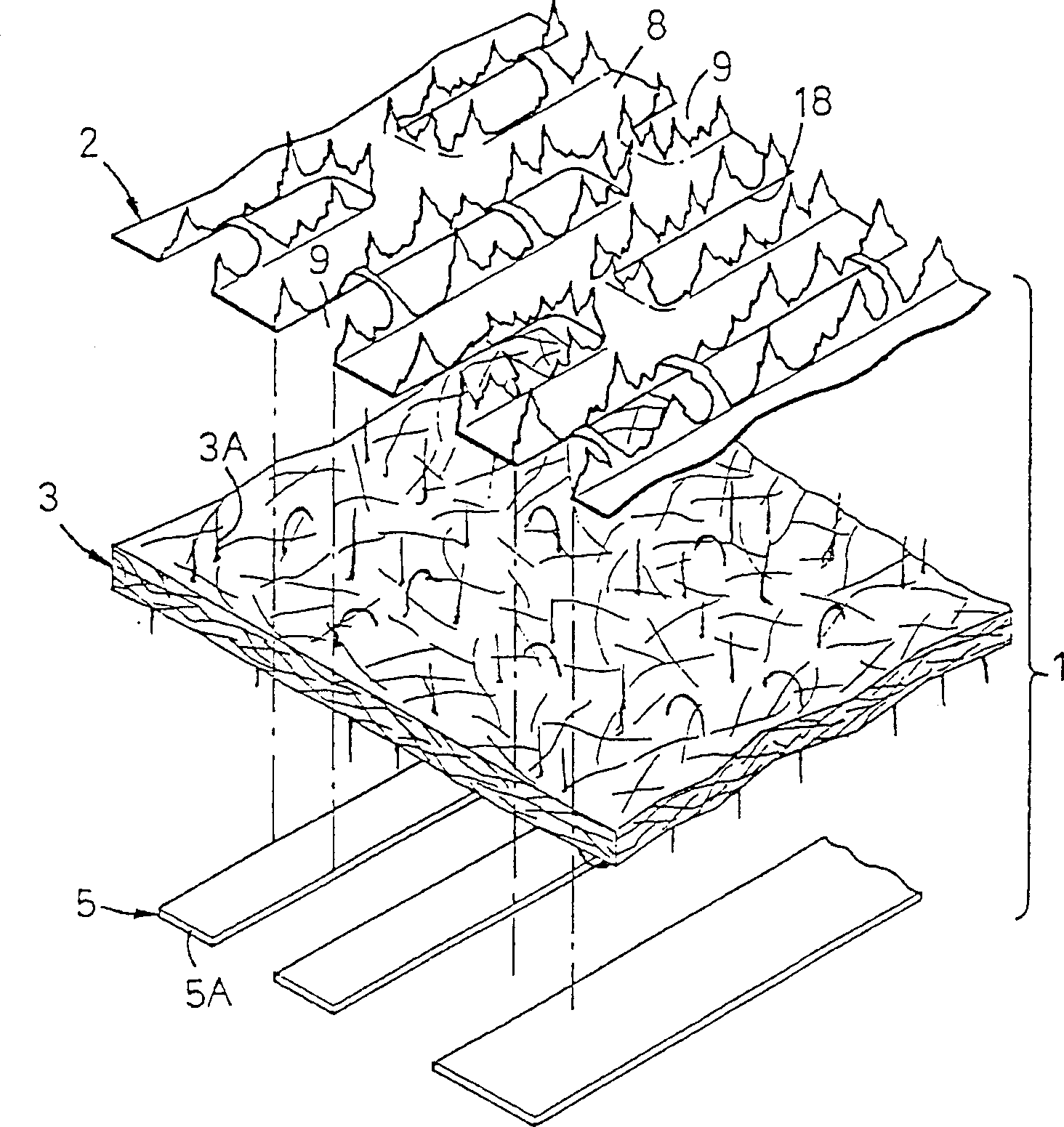

[0049] Figure 1 is a perspective view of a liquid-permeable surface layer 1 used in a disposable diaper or sanitary napkin, figure 2 is a perspective view showing the structural components of the surface layer 1 in a vertically exploded manner. The surface layer 1 comprises a top plastic film layer 2, a bottom plastic film layer 5, a fibrous assembly layer 3 between these two film layers 2,5.

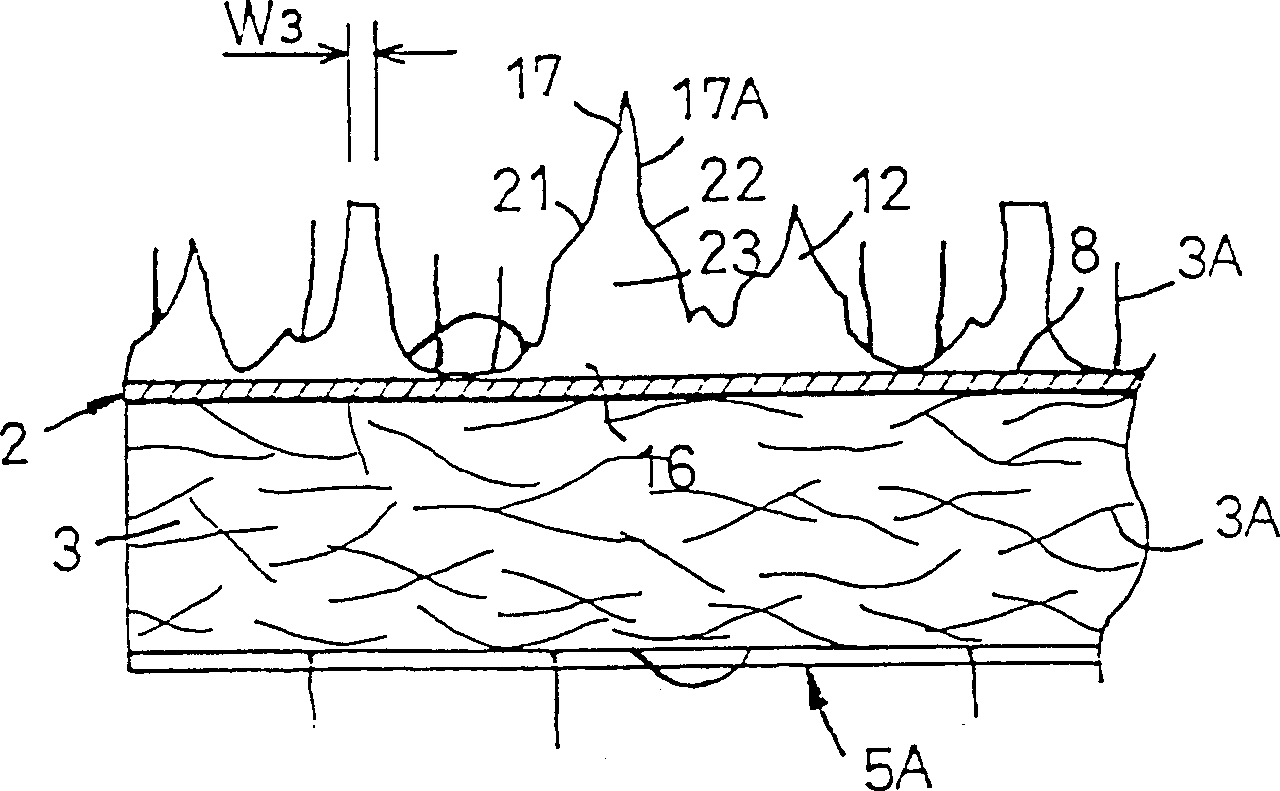

[0050] The above-mentioned film layer 2 has flexibility, and it includes: a flat part 8, which refers to a plurality of substantially flat parts extending parallel to each other along the direction shown by the double-headed arrow Y; a plurality of openings 9, It is located between the adjacent flat parts 8, extending along the arrow Y direction; the bridging part 10, which extends from the opposite edge part 18 in the adjacent flat parts 8 toward the direction shown by the double arrow X, and spans The opening 9 ; the upright portion 12 extending upward at the edge portion 18 of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com