Cooking device and integrated cooker with same

A cooking device and air inlet technology, applied in the field of integrated stoves, can solve the problems of affecting the baking effect, high steam generator power, and inability to exhaust efficiently, so as to avoid excessive humidity, improve baking effect, and improve exhaust The effect of gas efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

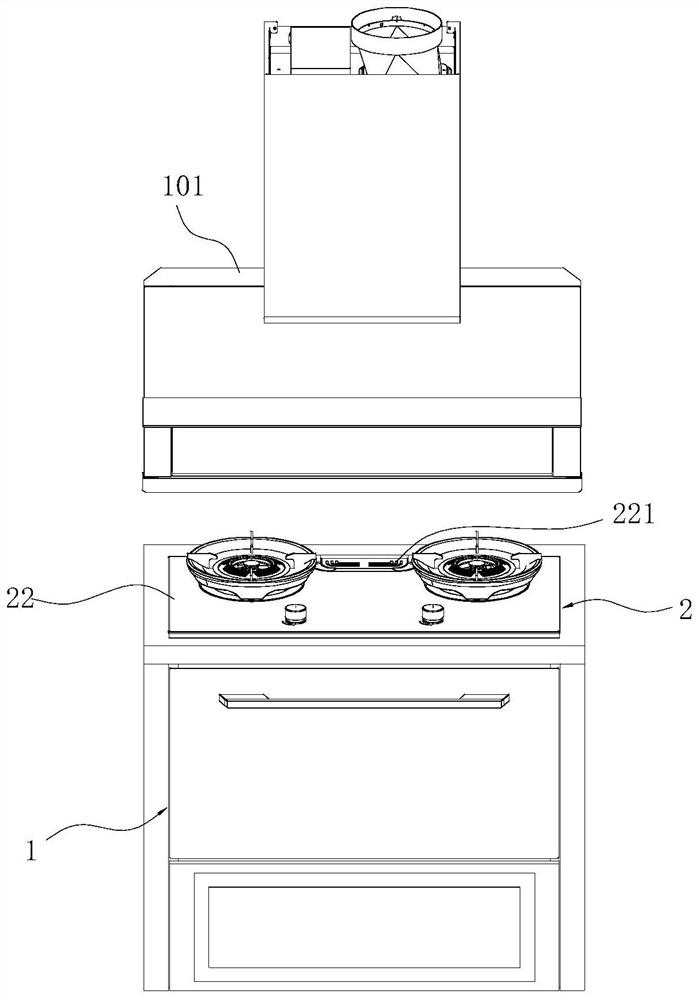

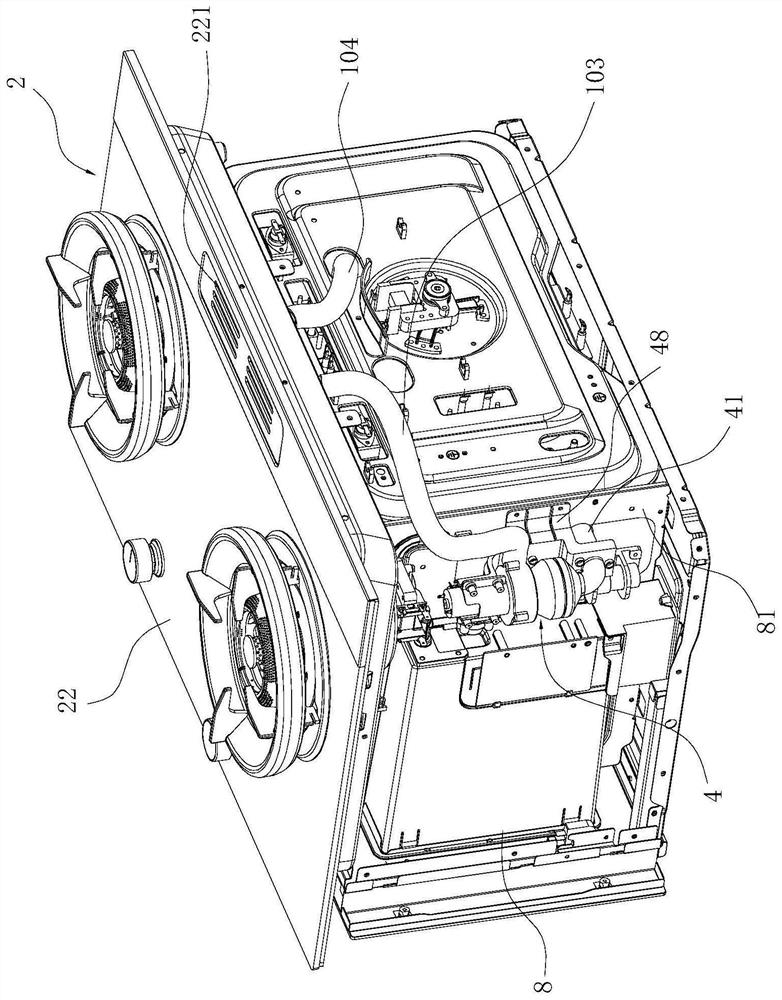

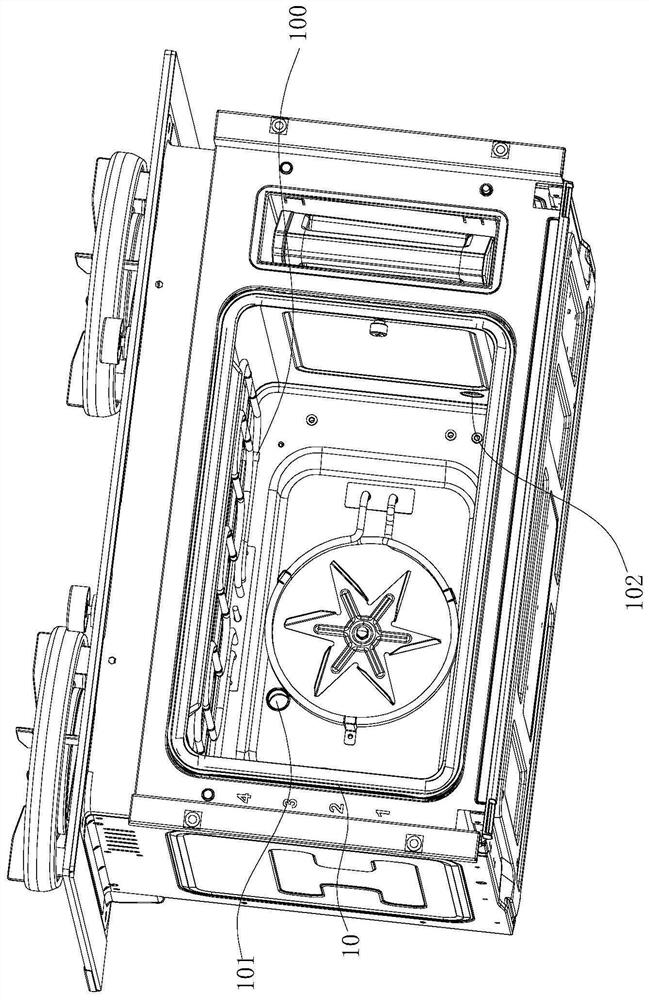

[0055] Such as Figure 1-9 As shown, an integrated cooker includes a cooking device 1 with an inner container 10 and a cooker 2 arranged on the cooking device 1. The inner container 10 has an exhaust port 101 and an air suction port 102, and the air suction port 102 is used for Air is drawn outward from the interior of the liner 10, and the cooker 2 includes a cooker shell with an exhaust cavity 30 inside, the cooker shell includes a chassis 21 with an upper opening and a panel 22 that is covered on the chassis 21, the panel 22 The rear side is provided with an exhaust window 221 communicating with the above-mentioned exhaust chamber 30, and the above-mentioned exhaust chamber 30 is respectively provided with a first air inlet 31 and a second air inlet 32, and the above-mentioned exhaust port 101 and the air suction port 102 are respectively It is in fluid communication with the first air inlet 31 and the second air inlet 32 . In this way, the gas in the liner 10 can be dra...

Embodiment 2

[0066] Such as Figures 10-14 As shown, the difference from Embodiment 1 is that in this embodiment, a control valve for controlling the opening and closing of the extraction air inlet 41 is installed on the housing 40 . In this way, the opening and closing of the air pump 4 can be realized by the control valve, and then the control of the exhaust of the inner bag 10 can be realized. Further, the inner cavity of the housing 40 also includes an air intake chamber 405, the air intake chamber 405 extends vertically and the above-mentioned suction air inlet 41 is opened on the wall of the air intake chamber 405, and the air intake chamber 405 The upper port communicates with the lower port of the second air guiding chamber 404 , and the upper port of the second air guiding chamber 404 communicates with the lower port of the axial flow chamber 403 . The air intake efficiency of the air pump 4 can be improved by providing the air intake chamber 405 , thereby improving the air extra...

Embodiment 3

[0069] Such as Figure 15 with Figure 16 As shown, the difference from Embodiment 2 is that in this embodiment, the above-mentioned control valve is a stacked valve 7, and the shape of the above-mentioned second air guide chamber 404 is rounded, and the valve plate of the stacked valve 7 is hinged on the suction inlet. Air port 41 on. The stack valve 7 has the advantages of being less affected by the flow medium and having a large flow rate, and the second air guide chamber 404 designed in the shape of a rounded table can guide the airflow into the axial flow chamber 403 more comfortably.

[0070] In addition, the housing 40 includes a cylindrical first member 40a, the upper part of the inner cavity of the first member 40a constitutes the centrifugal chamber 401, and a motor seat is arranged above the first member 40a, and the motor seat includes a The disc-shaped base 51 of the central hole 510, the base 51 is covered on the upper opening of the first member 40a, and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com