Turning surface roughness prediction method based on tool parameters and material parameters

A technology of surface roughness and material parameters, which is applied in the direction of manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problems of increasing prediction error, affecting surface roughness, lacking, etc., and achieve the effect of improving prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

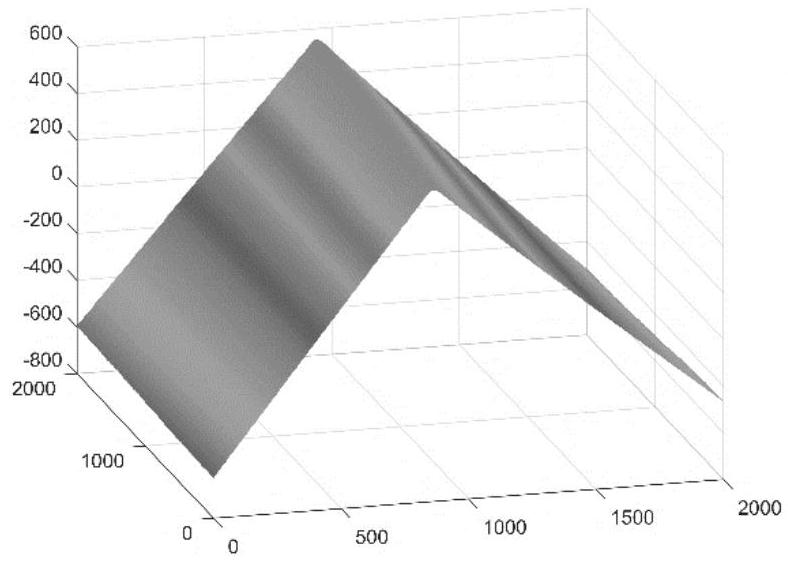

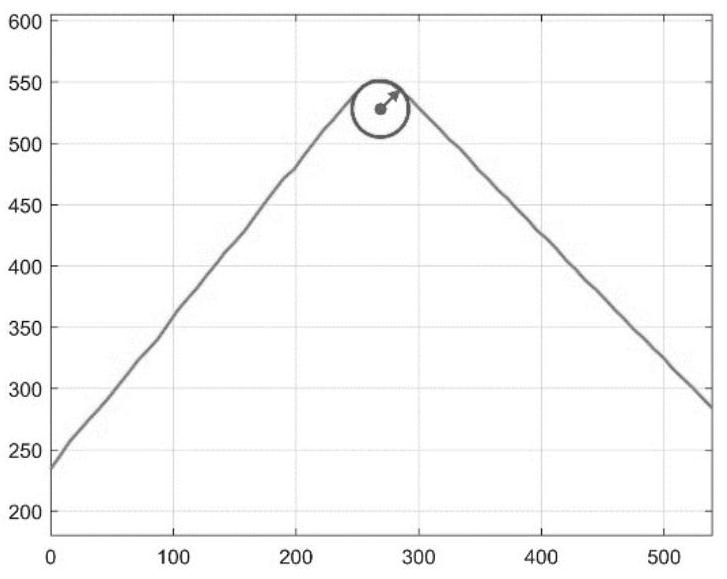

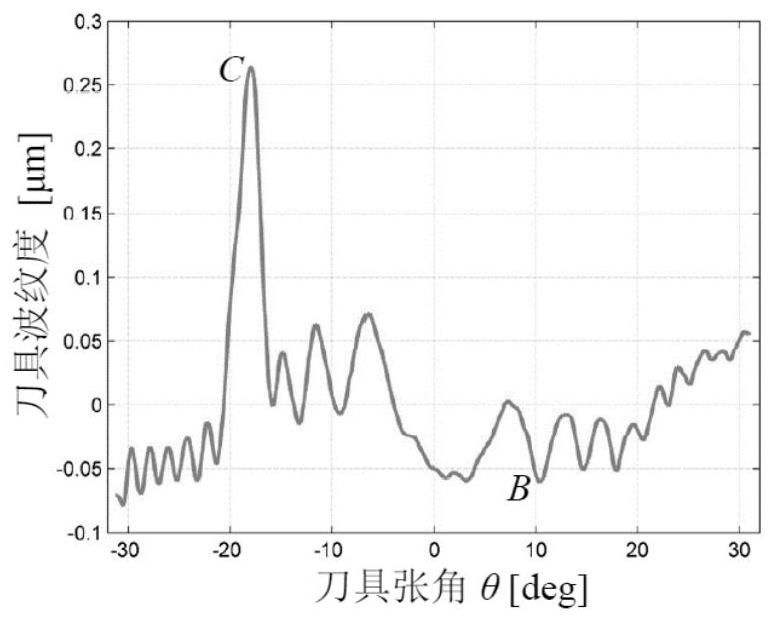

Image

Examples

Embodiment 1

[0063] Cutting experiments were carried out to verify the method. The workpiece material is made of fine-grained optical-grade aluminum alloy, the processing equipment is Nanoform 700Ultra ultra-precision machining machine tool, the tool is made of natural single crystal diamond tool, the radius of the arc of the tool tip is 1830.4 μm, the radius of the blunt circle of the tool cutting edge is 52.8nm, and the cutting depth d is 5 μm . The results of feed per revolution f, surface roughness prediction and measurement are shown in Table 1.

[0064] Table 1

[0065]

[0066] The table shows the comparison results of the predicted and measured values of surface roughness, in which the surface roughness data is obtained using an atomic force microscope with a measurement range of 70 μm × 70 μm. The formula for calculating the absolute forecast error is δ=|R t-m -R t-c |, the calculation formula of relative prediction error is η=|R t-m -R t-c | / R t-m ×100%, where R t-m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com