Automatic feeding and stirring equipment for premixed mortar for building construction and use method thereof

A technology for automatic feeding and ready-mixed mortar, applied in cement mixing devices, chemical instruments and methods, clay preparation devices, etc. The effect of convenient and sufficient mixing, novel design, and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

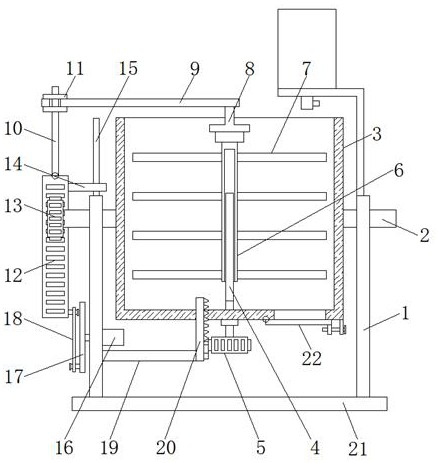

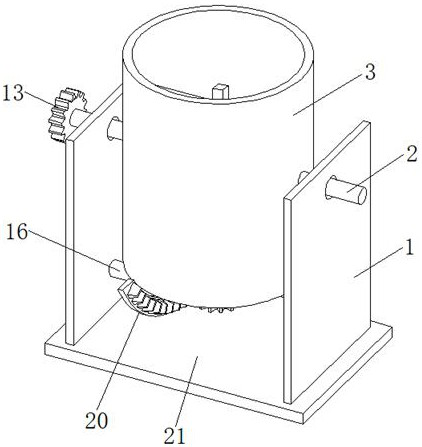

[0030] refer to Figure 1-2 , Figure 4-5 : A kind of automatic feeding and mixing equipment for ready-mixed mortar in construction, including two support plates 1, and a mixing tank 3 is rotatably connected between the two support plates 1, and the inside of the mixing tank 3 is provided with a lifting and stirring mechanism, which is located at The supporting plate 1 on the left side is provided with a lifting mechanism, and the bottom of the mixing bucket 3 is provided with a driving mechanism.

[0031] In the present invention, the lifting and stirring mechanism includes a transmission shaft 4 that is rotatably connected to the bottom barrel wall of the mixing tank 3. The bottom end of the transmission shaft 4 is fixedly connected with a first gear 5, and the outer movable sleeve of the transmission shaft 4 is provided with a sleeve 6. , the outer ring array of the casing 6 is provided with a plurality of stirring rods 7, the lifting mechanism includes a fixed plate 8 tha...

Embodiment 2

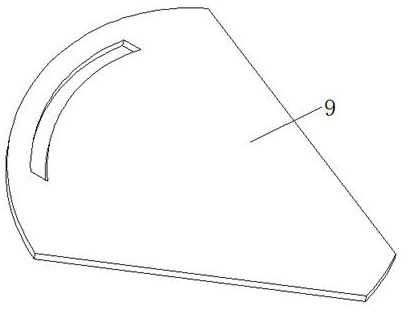

[0035] refer to Figure 1-5: a kind of automatic feeding and mixing equipment of ready-mixed mortar for building construction, the lifting mechanism includes a fixed plate 8 that is rotatably connected to the top of the casing 6, the top of the fixed plate 8 is fixedly connected with a lifting plate 9, and the internal movable cover of the lifting plate 9 A push-pull rod 10 is provided, and the push-pull rod 10 is fixedly connected with a limit plate 11 positioned at the top and bottom of the lifting plate 9. The bottom end of the push-pull rod 10 is hinged with a first rack 12, and the top of the right side of the first rack 12 is fixed. Be connected with movable plate 14, the inner movable cover of movable plate 14 is provided with guide bar 15, and the bottom end of guide bar 15 is fixedly connected with support plate 1, the front of first rack 12 is provided with second gear 13, and the second The gear 13 is meshed with the first rack 12 for transmission, and the drive mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com