Natural gas liquefaction treatment device adopting composite refrigeration liquefaction

A technology for liquefied natural gas and liquefaction treatment, which is applied in the field of compound refrigeration liquefied natural gas liquefaction treatment devices, and can solve the problems affecting the purity and mixing of liquefied natural gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

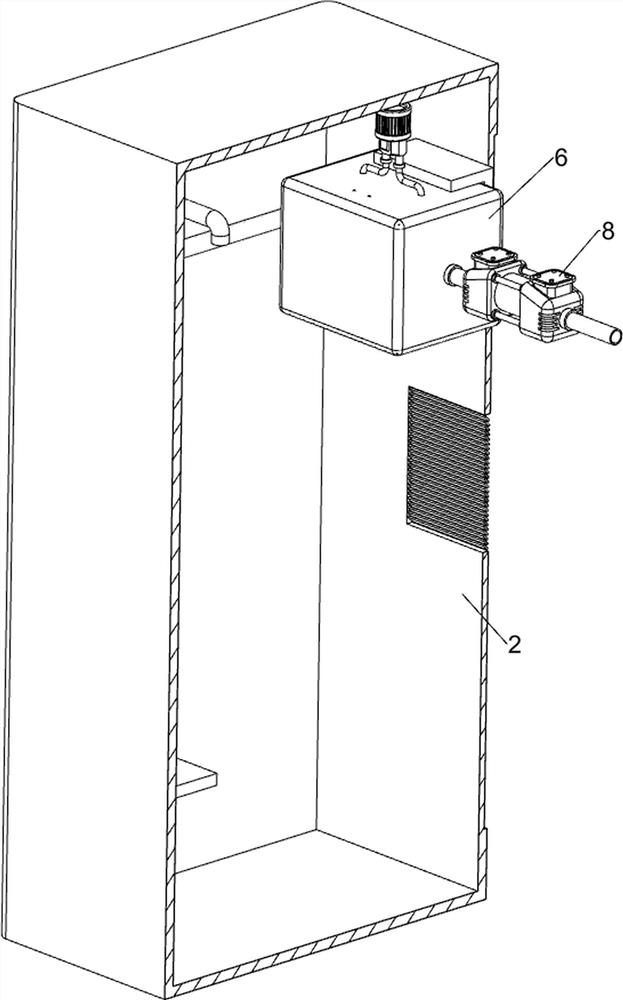

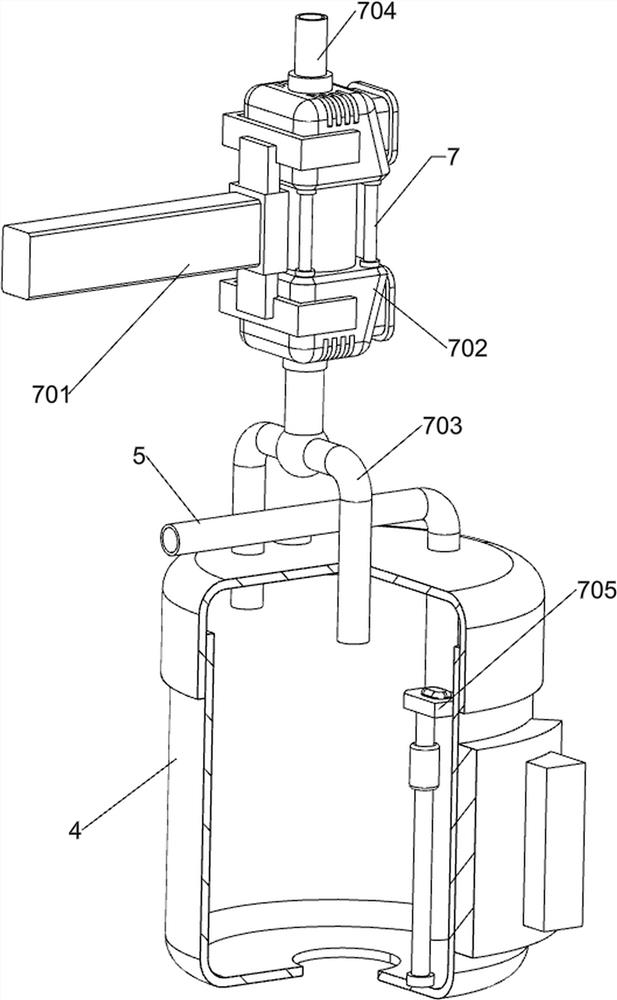

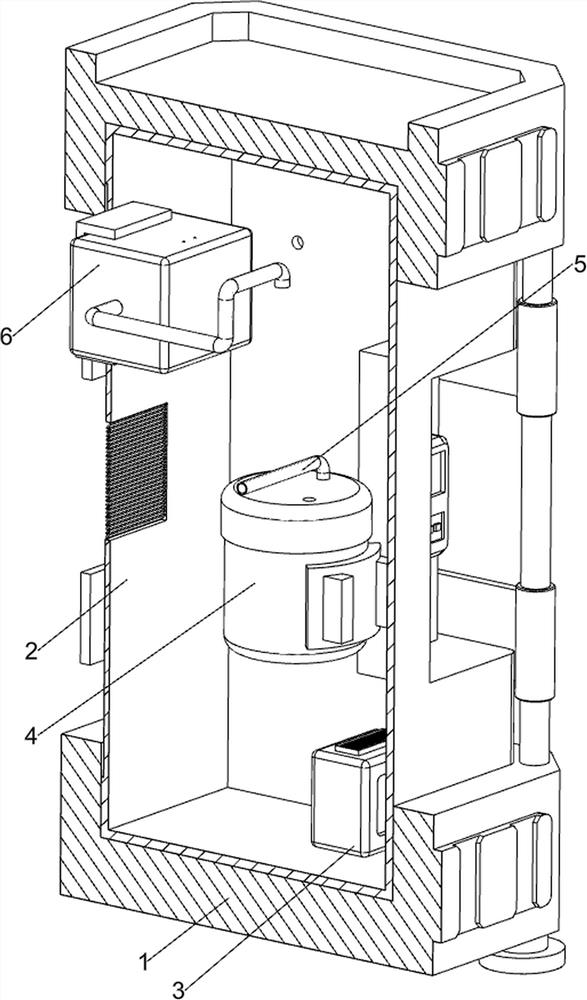

[0040] A compound refrigeration liquefied natural gas liquefaction treatment device, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 17 As shown, it includes a base 1, a casing 2, a sealed tank 4, a natural gas inlet pipe 5, a condensation box 6, an air extraction component 7, a condensation component 8, a drainage component 9 and a water injection component 12, and the top of the base 1 is fixedly connected with the casing 2, The middle part of the casing 2 is connected with a sealed tank 4 by bolts, and the bottom of the sealed tank 4 has a water outlet. The left side of the inner wall is equipped with an air extraction assembly 7, which is connected between the airtight tank 4 and the condensation box 6, the condensation box 6 is provided with a condensation assembly 8, the lower part of the airtight tank 4 is provided with a drainage assembly 9, and the inner wal...

Embodiment 2

[0047] On the basis of Example 1, such as Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 18 and Figure 19 As shown, a control assembly 10 is also included, and the control assembly 10 includes a first air intake pipe 1001, a ball valve 1002, a second gear 1003, a second guide sleeve 1004, a U-shaped rod 1005, a first spring 1006 and a second rack 1007 The left side of the natural gas intake pipe 5 is connected with a first intake pipe 1001, a ball valve 1002 is rotated on the first intake pipe 1001, a second gear 1003 is connected to the front and rear sides of the ball valve 1002, and a second gear 1003 is connected to the front and rear symmetrically on the left side of the sealed tank 4. U-shaped rod 1005 is slidingly arranged between the second guide sleeve 1004 and the second guide sleeve 1004, and the upward movement of the first baffle plate 901 will drive the U-shaped rod 1005 to move upward, and the front and back between the U-shaped r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com