Efficient cooling mechanism for metal material machining and using method of efficient cooling mechanism

A technology of cooling mechanism and metal materials, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve problems such as obstructing sight, cooling water and polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

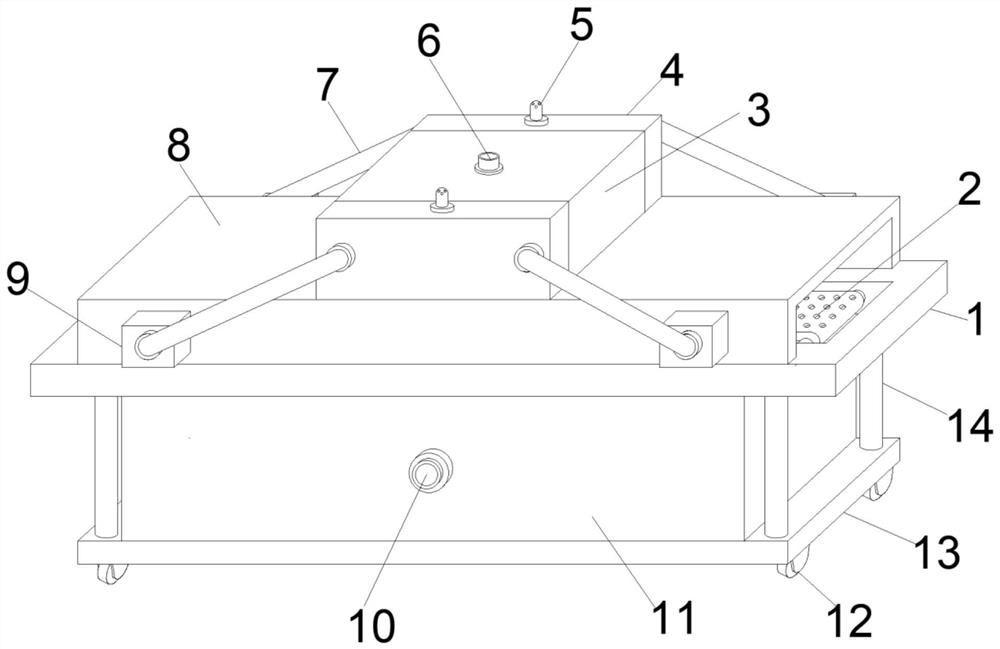

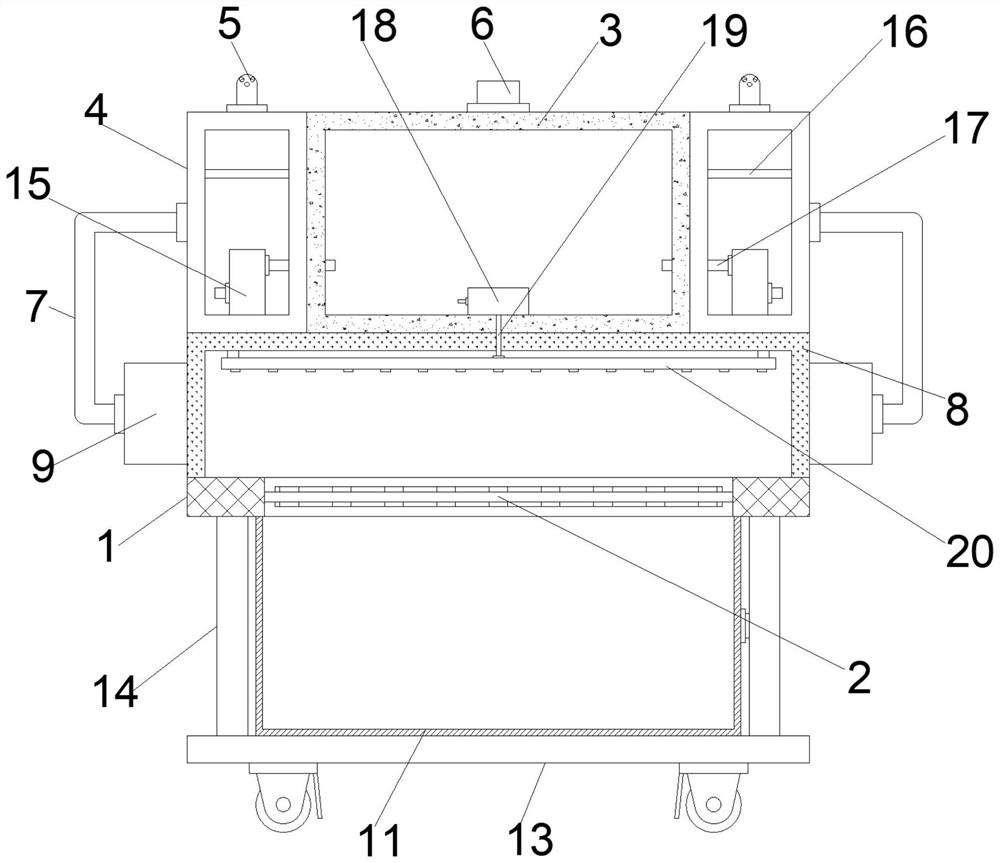

[0031] Such as Figure 1-2 As shown, the embodiment of the present invention provides a high-efficiency cooling mechanism for metal material processing and its use method, including the following steps:

[0032] S1. First connect the device with other metal processing modules, then start the transmission structure 2, the mist extraction fan 9 and the waterproof pump 18, the metal that needs to be cooled will be transferred from one end to the other through the transmission structure 2, and the waterproof pump 18 is used for pumping 3 water away from the water storage tank, which is convenient for metal cooling;

[0033] S2. During the process of conveying metal in the conveying structure 2, the waterproof pump 18 will inject the cooling water in the water storage tank 3 from the connecting water pipe 19 into the spraying structure 20. The spraying structure 20 can make the cooling water spray more evenly, and at the same time spray the structure 20 The cooling water will be s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com