Instrument and method for measuring high-temperature thermal expansion of concrete

A concrete and warm technology, applied in the field of measuring instruments, can solve the problem of being unsuitable for the determination of high temperature thermal expansion of concrete, and achieve the effect of ensuring service life, eliminating temperature control delay, and ensuring high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

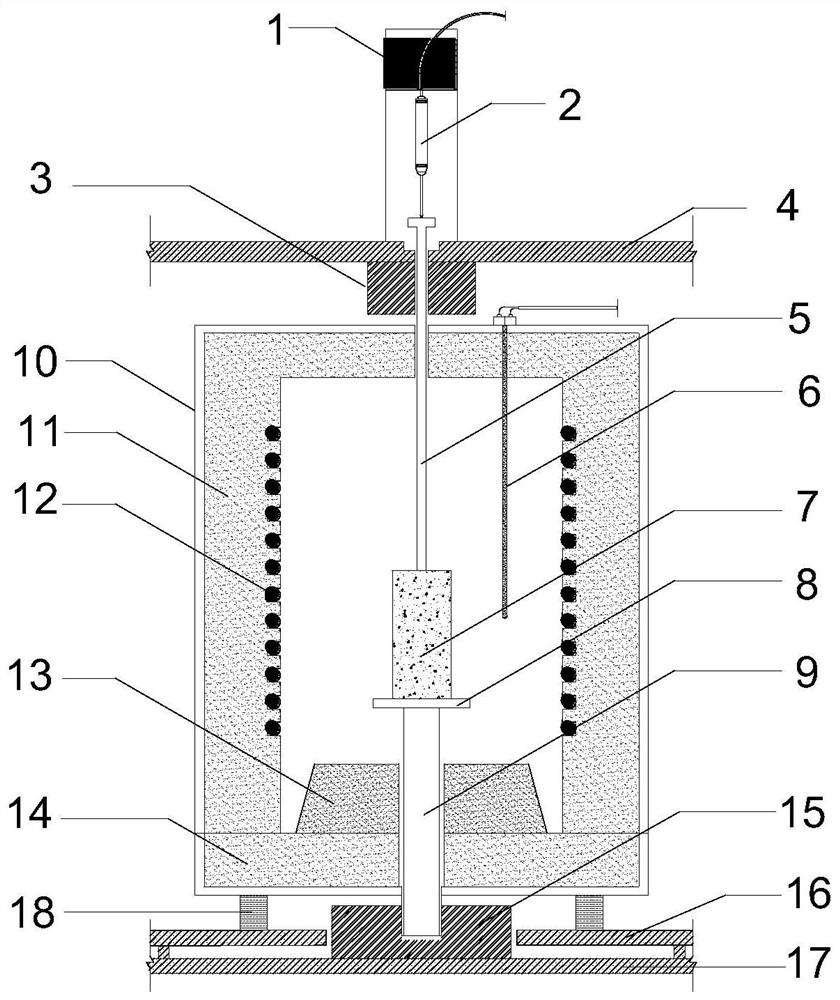

Method used

Image

Examples

Embodiment 1

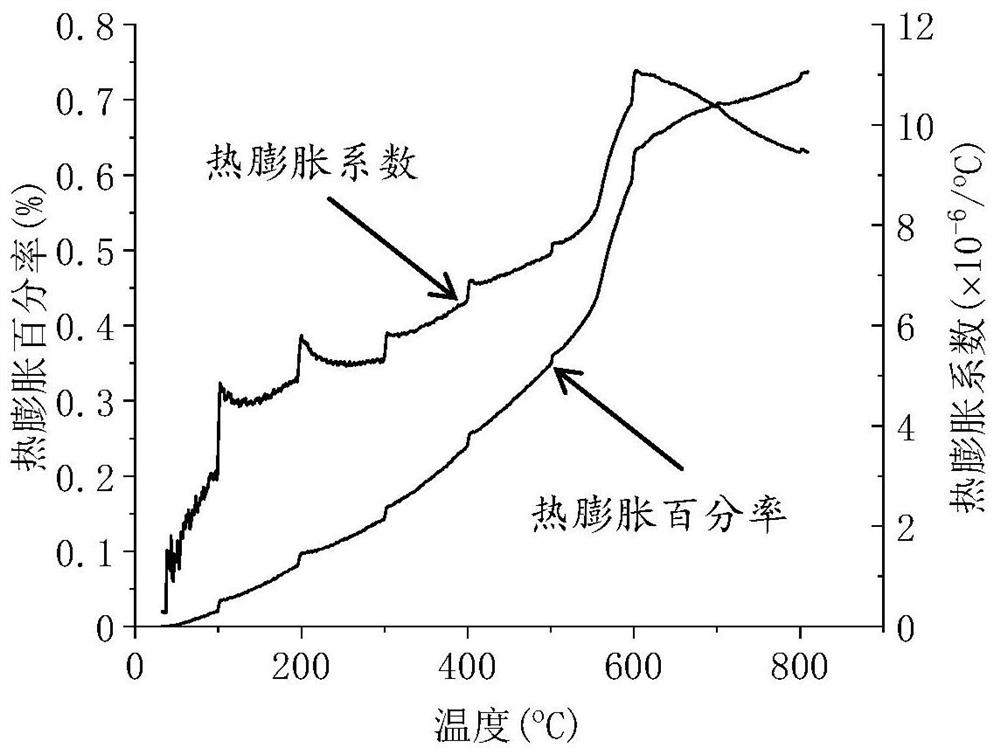

[0089] Embodiment 1: The high-temperature thermal expansion of concrete at 30-810° C. is measured with a water-binder ratio of 0.4 and a maximum aggregate particle size of 16 mm using the instrument and method for measuring high-temperature thermal expansion of concrete of the present application.

[0090] The concrete sample is a prism sample with a bottom side length of 50mm (more than 3 times the maximum aggregate particle size of 48mm) and a height of 100mm; the auxiliary test is used to determine the heating rate of the sample is 2°C / min, and the constant temperature time of each constant temperature point is shown in the table 1; the 100mm high quartz standard sample is used to measure the expansion compensation value; the measurement results of thermal expansion percentage and thermal expansion coefficient are as follows figure 2 shown.

[0091] Table 1 Constant temperature time of each constant temperature point

[0092]

Embodiment 2

[0093] Embodiment 2: Using the concrete high-temperature thermal expansion measuring instrument and measuring method of the present application, the water-binder ratio is 0.2, the maximum aggregate particle size is 5 mm, and the steel fiber ultra-high-strength concrete with a length of 13 mm is 30 to 825 ° C. high temperature thermal expansion.

[0094] The concrete sample is a prism sample with a bottom side length of 50mm (more than 3 times the steel fiber length of 39mm) and a height of 100mm; the auxiliary test is used to determine the heating rate of the sample is 2°C / min, and the constant temperature time of each constant temperature point is shown in Table 2 100mm high quartz standard sample was used to determine the compensation value; due to the relatively low water-gel ratio, anti-explosion treatment was carried out by drying at 105°C for 3 days; the measurement results of thermal expansion percentage and thermal expansion coefficient were as follows: image 3 shown....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com