Magnetostrictive patch type sensor capable of efficiently exciting spiral circumferential lamb waves and working method of magnetostrictive patch type sensor

A magnetostrictive and working method technology, applied in the direction of instruments, scientific instruments, processing detection response signals, etc., to achieve the effect of rapid pipeline defect detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

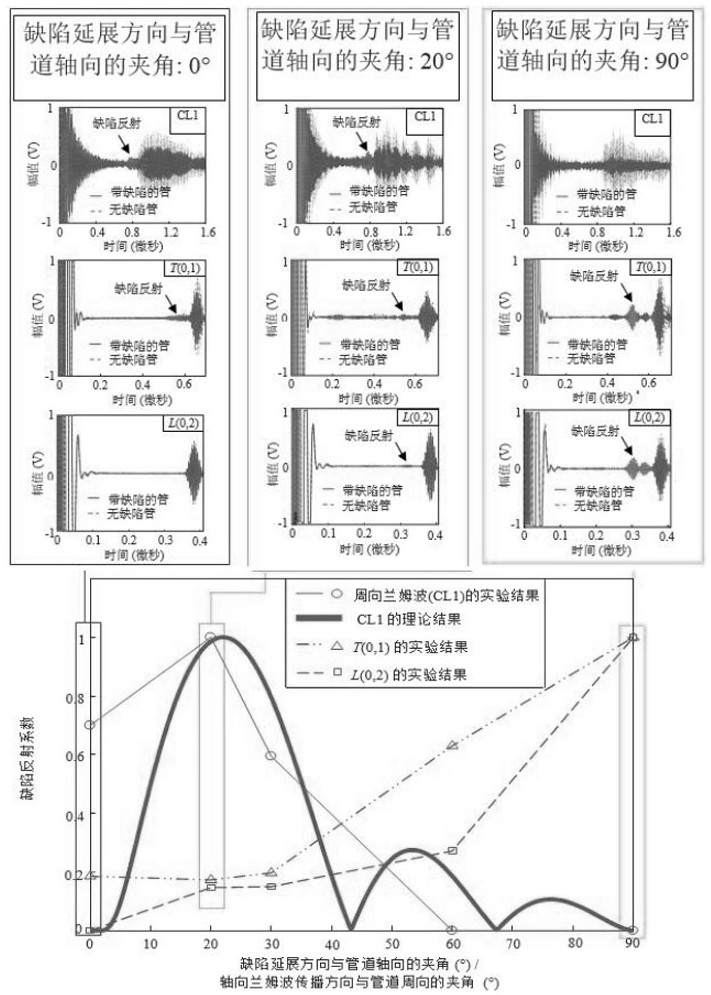

[0115] Examples of axial defect localization by helically propagated circumferential Lamb waves:

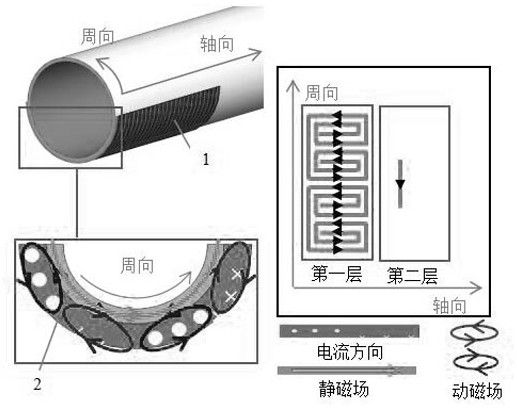

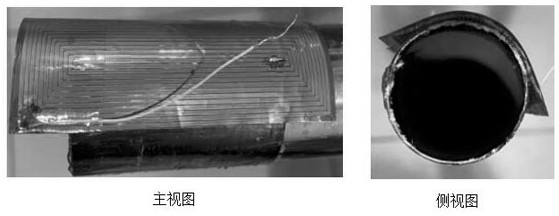

[0116] 1) Paste the magnetostrictive material with a width of 50mm and a length equivalent to the circumference of the pipe on the pipe;

[0117] 2) A flexible printed coil that efficiently excites helically propagating circumferential Lamb waves is pasted on the magnetostrictive material;

[0118] 3) Using the self-excitation self-reception mode, the sine wave signal modulated by the 5-period Hanning window is input through the flexible printed coil that efficiently stimulates the helical propagation of the circumferential Lamb wave, and the received signal is collected;

[0119] 4) To observe the defect reflection signal, use the relationship between the axial propagation velocity of the helically propagated circumferential Lamb wave, the time corresponding to the defect reflection signal, and the axial position of the defect. The axial position of the axial defect is calculat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com