Ultrasonic testing method for weld area of Stellite alloy sheet of steam turbine blade

A technology of stellite alloy sheet and steam turbine blade, which is applied in the field of ultrasonic detection method and probe in the weld area of stellite alloy sheet, can solve the problem of small size of stellite alloy sheet and base material, reduce detection cost, improve Detection efficiency, easy to distinguish the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] Embodiment: Adopt the method of the present invention to carry out ultrasonic detection to the brazing area of a certain blade Stellite alloy sheet, find that there is an unfused area, can determine the size of the defect, and use the length measurement method to obtain the three detection results in the length direction: 12mm, 13mm , 13mm.

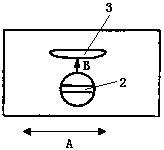

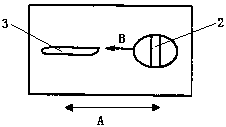

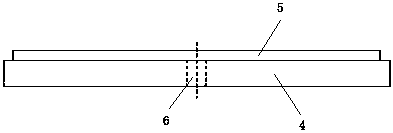

[0029] Image 6 with Figure 7 Among them, T is the launch wave, B is the bottom wave, and F is the defect wave.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com