A Few-Sample Defect Detection Method Based on Metric Learning

A metric learning and defect detection technology, applied in the field of defect detection of large-scale assembly parts, can solve the problems of low intelligence, long time consumption, inaccurate features, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

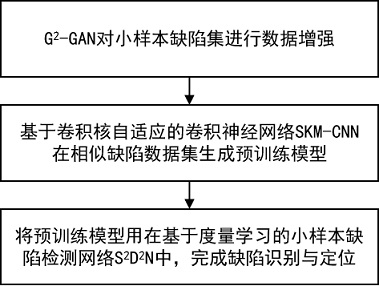

[0048] see Figure 1-4, the present invention provides a small sample defect detection method based on metric learning, which specifically includes the following steps:

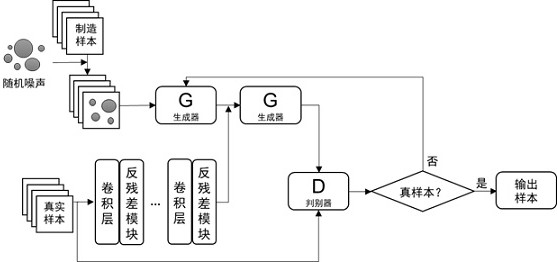

[0049] Step (1): Pass G 2 - GAN adversarial network for data augmentation of small sample defect datasets;

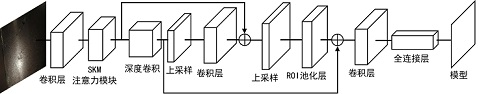

[0050] Step (2): Based on the self-adaptive convolutional neural network SKM-CNN of the convolution kernel, the features of the defect data set (auxiliary data set) similar to the small sample defect data set to be detected are extracted to generate a pre-training model;

[0051] Step (3): Migrate the pre-trained model to a few-shot defect detection network S based on metric learning 2 D 2 In N, the rapid identification and localization of defects is realized by the method of first target feature extraction and then metric learning.

[0052] In the step (1), thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com