Electrode bar horizontal cutting device for electrolytic aluminum

A technology of electrode rods and electrolytic aluminum, which is applied in the field of aluminum electrolysis, can solve the problems of inability to accurately ensure the same length of electrode rods and low processing efficiency, and achieve the effects of improved cutting efficiency, convenient operation, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

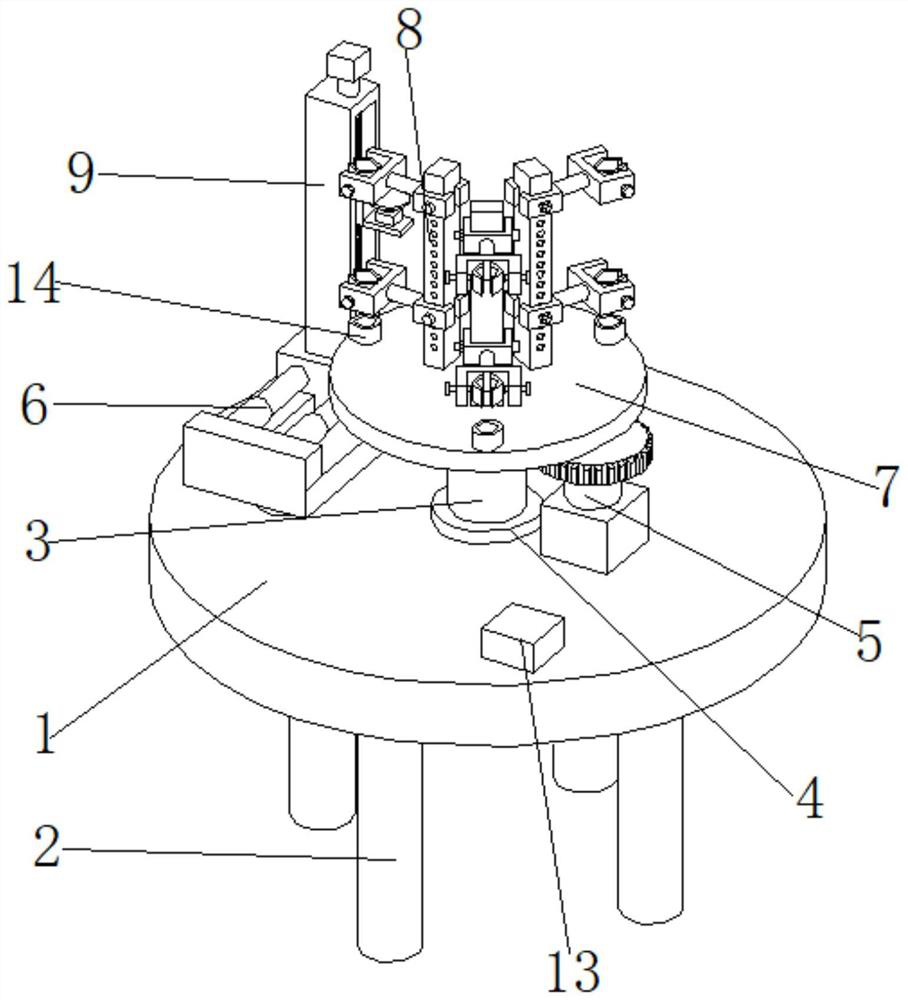

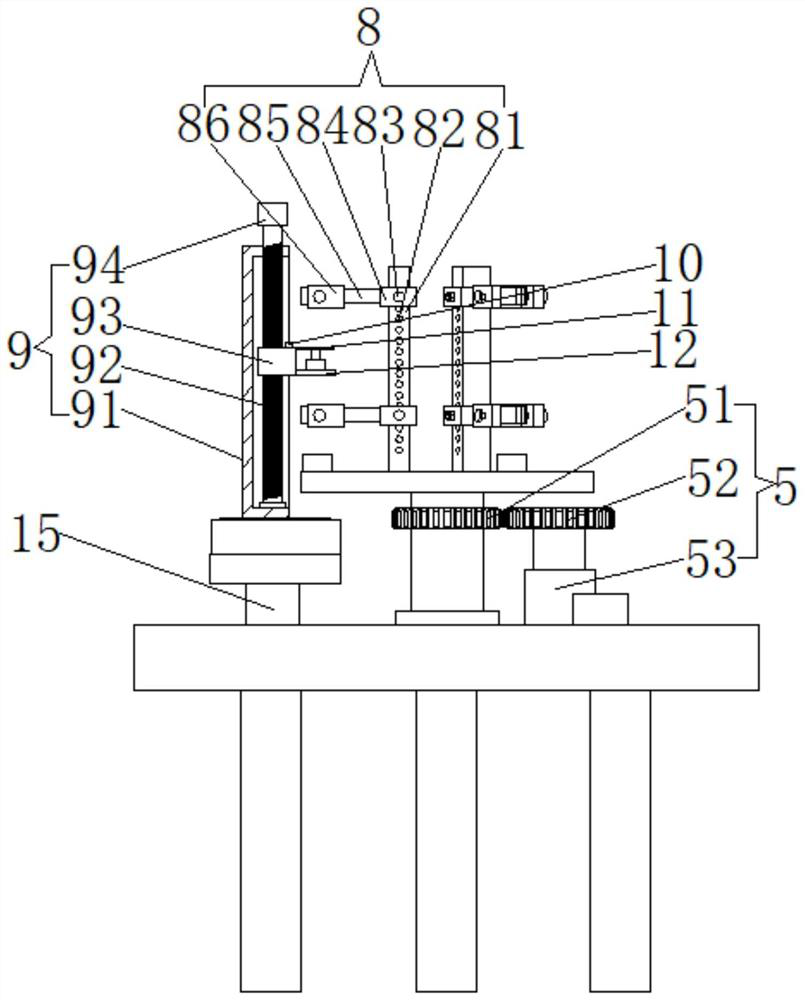

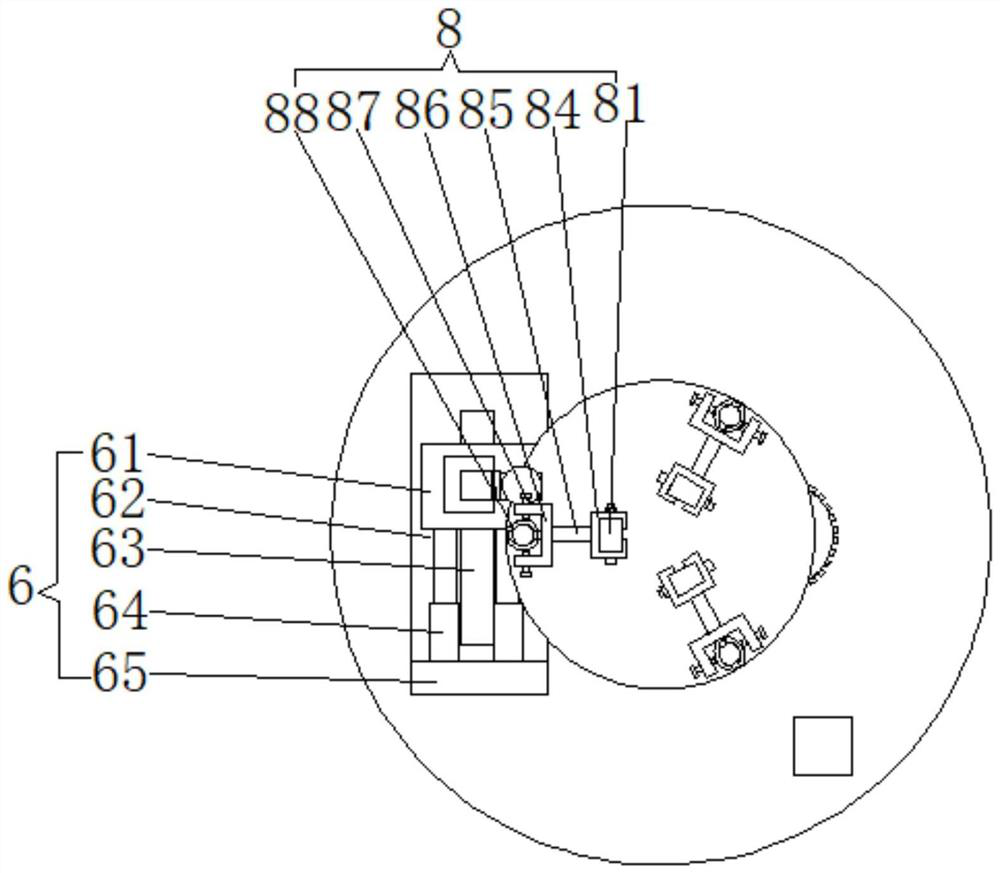

[0019] Example 1: See Figure 1-3 , the present invention provides a technical solution: an electrode rod flat cutting device for electrolytic aluminum, comprising a bottom plate 1, the lower end surface of the bottom plate 1 is provided with a leg 2, and the upper end surface of the bottom plate 1 is rotatably connected with a rotating shaft 3 through a bearing 4, One side of the rotating shaft 3 is provided with a driving mechanism 5 for driving its rotation. The driving mechanism 5 includes a driven gear 51, a driving gear 52 and a driving motor 53. The driven gear 51 is sleeved on the outer surface of the rotating shaft 3. The driving gear 52 and the The driven gear 51 is meshed and connected, and the driving gear 52 is connected with the output shaft of the driving motor 53. The cooperation of the driving gear 52 and the driven gear 51 drives the rotating shaft 3 to rotate, which can ensure the stability of the rotating shaft 3. The upper end of the rotating shaft 3 is pro...

Embodiment 2

[0021]Embodiment 2: The difference from Embodiment 2 is that the outer surface of the vertical rod 81 is evenly distributed with a plurality of perforations 82 along its height direction, and the sliding sleeve 84 is provided with through holes corresponding to the positions of the perforation 82. 84 and the vertical rod 81 are fixed together by the fixed screw rod 83, and the position of the sliding sleeve 84 can be adjusted according to the difference in the cutting length required for each batch of electrode rods by providing a plurality of through holes on the vertical rod 81 to ensure that the clamping Block 84 for stability of electrode rod clamping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com