A kind of flour processing feeding equipment and flour processing equipment

A feeding equipment and feeding technology, which is applied in the field of flour processing, can solve the problems of easy blocking of the feeding port and blockage, and achieve the effects of reasonable structure, reduced labor cost, and simple and practical structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

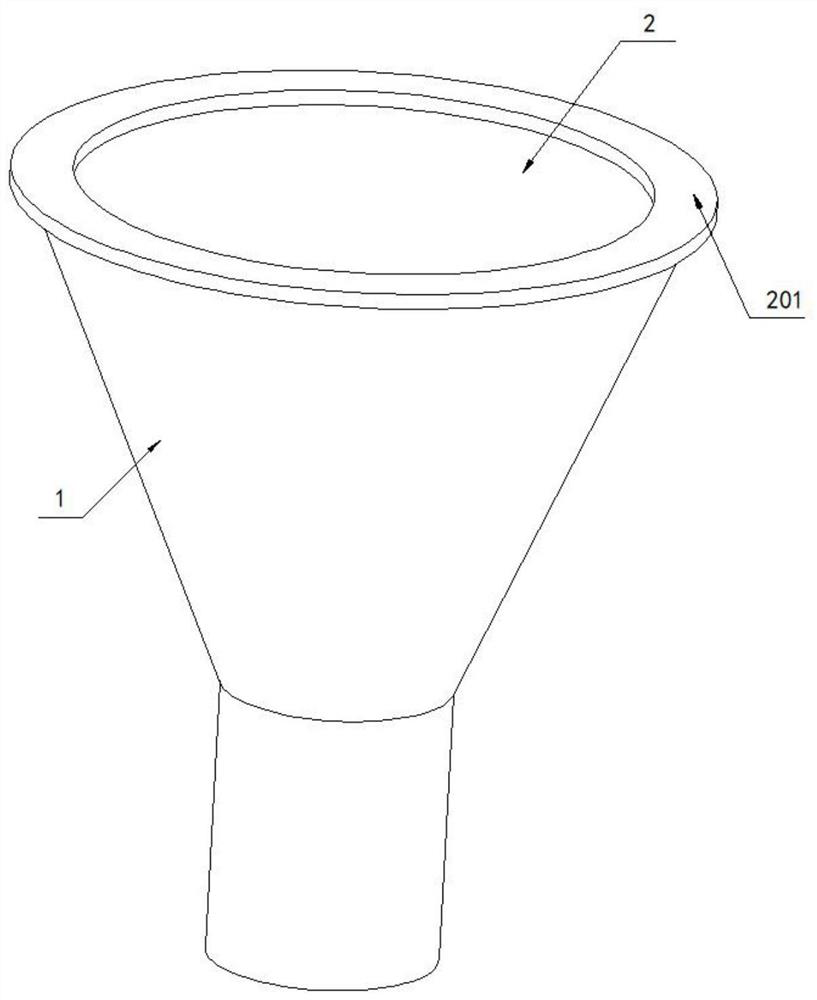

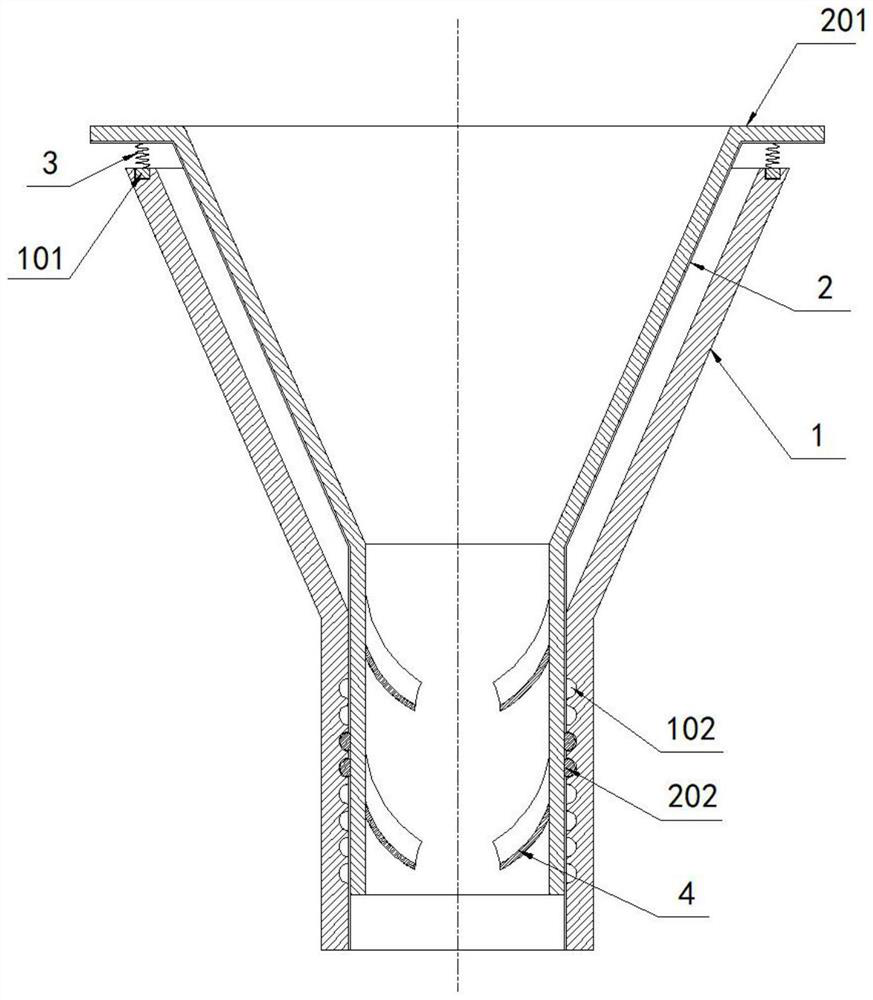

[0037] like Figure 1-Figure 2 As shown, a flour processing and feeding equipment proposed by the present invention includes: an outer feeding hopper 1; The straight outer wall of 2 is matched with the straight inner wall of the feeding outer hopper 1 by screw drive; spring 3, spring 3 is arranged between the feeding outer hopper 1 and the feeding inner hopper 2, and the spring 3 is used to support the feeding inner hopper 2 to make the feeding There is a gap between the inner hopper 2 and the outer feeding hopper 1; and a blade 4, and at least one blade 4 is arranged on the inner wall of the straight cylinder of the inner feeding hopper 2.

[0038] As a specific embodiment of the present invention, as figure 2 As shown in the figure, a spiral groove 102 is arranged on the inner wall of the straight cylinder of the feeding hopper 1, and a spiral slider 202 is arranged on the outer wall of the straight cylinder of the feeding inner hopper 2. The spiral slider 202 is screwed i...

Embodiment 2

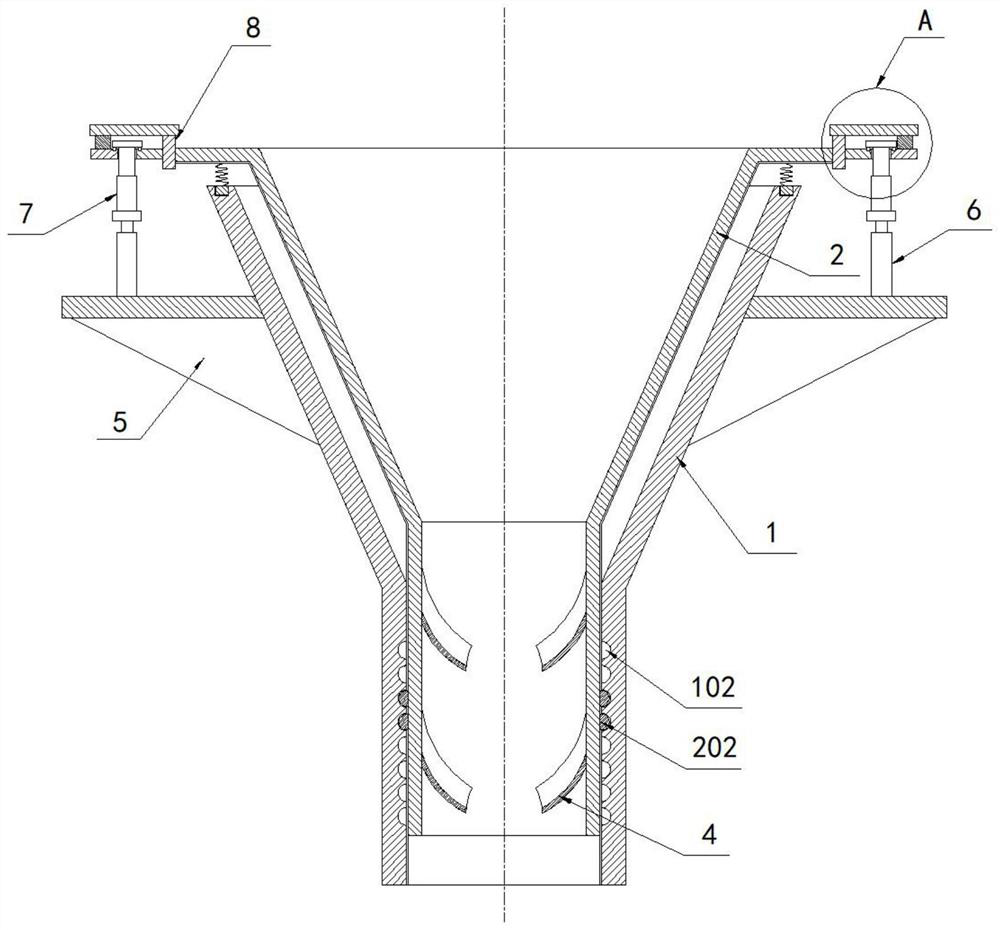

[0044] like Figure 3-Figure 5 As shown, the following technical solutions are added on the basis of the technical solutions of the above-mentioned embodiment 1:

[0045] As a specific embodiment of the present invention, as Figure 3-Figure 5 shown, including:

[0046] an annular slideway mechanism, which is concentrically fixed on the outer wall of the epitaxial ring plate 201;

[0047] Telescopic mechanism 6, at least two brackets 5 are fixed on the outer wall of the feeding bucket 1, a telescopic mechanism 6 is fixed on the top of each bracket 5, a telescopic rod 7 is fixed on the piston end of the telescopic mechanism 6, and the upper end of the telescopic rod 7 is fixed The sliding engagement is in the annular chute of the annular chute mechanism.

[0048] The telescopic mechanism 6 adopts a telescopic oil cylinder, a telescopic air cylinder or a push rod motor, preferably a telescopic oil cylinder or a telescopic air cylinder.

[0049] As a specific embodiment of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com