Winding device for building waterproof roll manufacturing

A technology of building waterproofing and winding devices, which is applied in the directions of winding strips, transportation and packaging, and thin material processing, etc. The effect of small workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

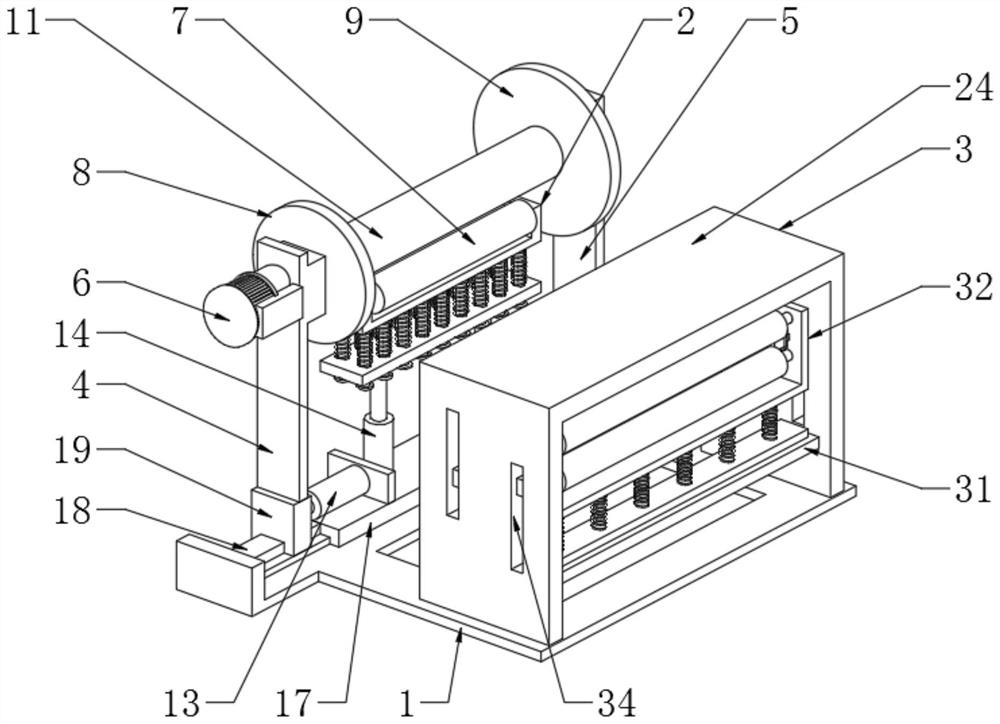

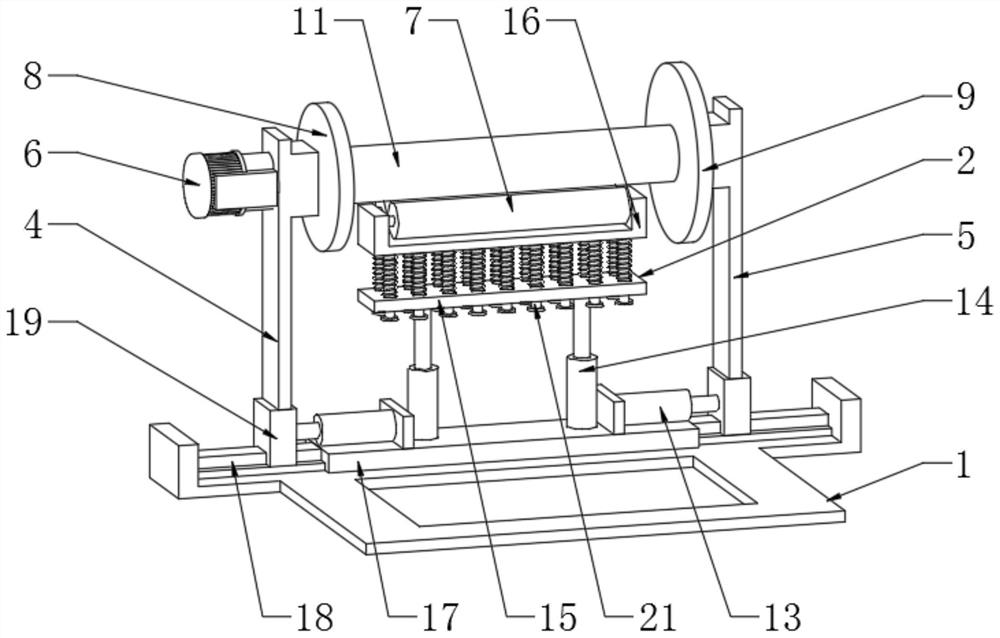

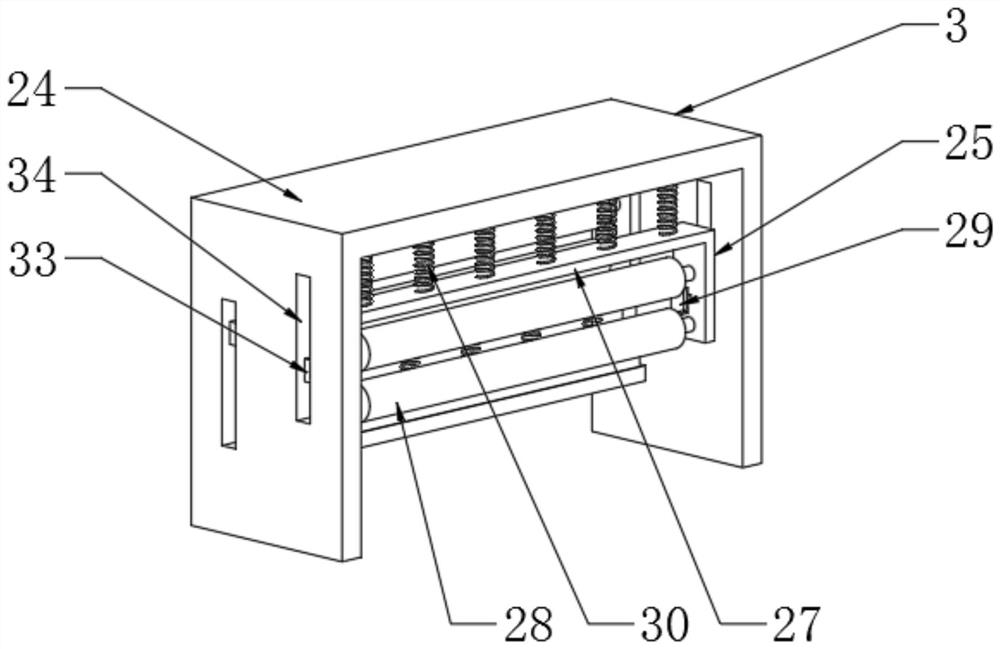

[0027] The specific embodiment is: when the winding roller 11 is installed, the hydraulic cylinders 13 at the bottom of the first support plate 4 and the second support plate 5 work, and the two hydraulic cylinders 13 work at the same time to push the first support plate 4 and the second support plate 5 respectively. , so that the first support plate 4 and the second support plate 5 are far away from each other, and then the winding roller 11 to be installed is placed on the compacting and unloading mechanism 2, and the winding roller 11 is located between the tops of the two compacting rollers 7 The gap between the winding rollers 11 is placed stably, and the two cylinders 14 work to push the first support 16 to move up. The first support 16 moves up to drive the winding rollers 11 to move upwards, so that the winding rollers 11 are located between the first turntable 8 and Between the second turntable 9, two hydraulic cylinders 13 contract and pull the first support plate 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com