Process for advanced treatment of coking wastewater and coupled fluorine ion removal

A coking wastewater, advanced treatment technology, applied in the coking wastewater advanced treatment stage organic matter, chromaticity and fluoride ion coupling removal, cyanide field, can solve the problem that affects the stable operation of the coking wastewater zero discharge treatment system, affects the life of the evaporation crystallizer, fluorine There are no problems such as treatment effect, and the effect of improving fluorine removal effect, stable effect and low treatment cost is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

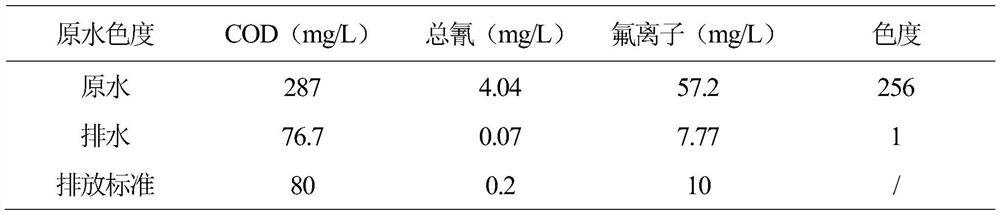

[0026] The first and second phase treatment project of coking wastewater in a company, the treated water comes from solvent dephenolization, wastewater after ammonia distillation, coal fine process drainage, chemical production process drainage, COG condensate water and various accident drainage, mainly by biological anoxic and aerobic treatment, mixed It consists of three parts: coagulation filtration treatment and sludge dehydration treatment. The design processing scale is 5800m 3 / d, handle direct efflux.

[0027] The COD content of the influent water in the physical and chemical treatment stage after biochemical treatment of coking wastewater is 150-500mg / L, and the cyanide content is 1-2mg / L. The chromaticity is in the range of 128-256 times, the fluoride is in the range of 30-60mg / L, and the wastewater discharge requirements meet the discharge limit value of pollutant discharge standard for coking chemical industry (GB16171-2012). Table 2 Newly established enterprise w...

Embodiment 2

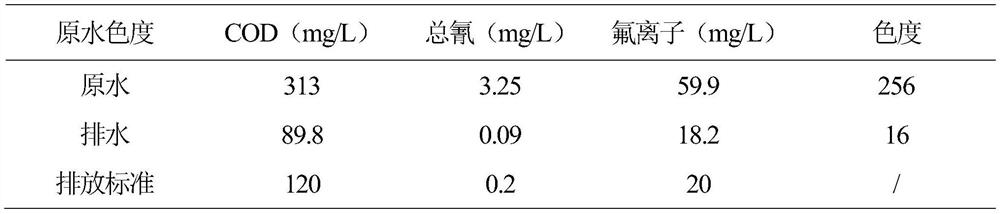

[0032] In the coking wastewater treatment area of a company, the raw water is composed of gas condensate water, residual ammonia water, ammonia distillation discharge liquid, and hydrogen production wastewater. The two-stage AO+physicochemical+constructed wetland process is mainly adopted. The design processing scale is 6200m 3 / h, handle direct efflux.

[0033] The COD content of the biochemical effluent is 200-600mg / L, and the cyanide content is 0.5-3mg / L. The chromaticity is in the range of 128-256 times, the fluoride is in the range of 30-70mg / L, and the direct discharge of wastewater is required to meet the indirect discharge standard of pollutants in the coking chemical industry.

[0034]In the physical and chemical treatment stage of biochemical effluent, the original physical and chemical treatment device was modified, and 400mg / L of BH type agent was added to the first physical and chemical reaction tank, stirred and reacted for 30min, and then entered into the sec...

Embodiment 3

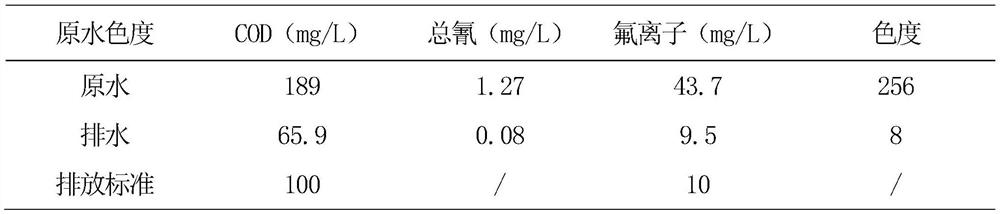

[0038] A coke oven wastewater treatment station adopts the technological process of pretreatment + biochemical treatment + post-treatment, and the volume of wastewater treated after biochemical treatment is about 140m 3 / h, the COD content of biochemical effluent is 200-300mg / L, the cyanide content is 0.5-2mg / L, the chromaticity is in the range of 128-256 times, and the fluoride is in the range of 30-40mg / L. After treatment, it enters the advanced treatment device and requires COD Content- <10mg / L.

[0039] In the physical and chemical treatment stage after the biochemical effluent, set up a coagulation reaction tank and a sedimentation tank. Add 300mg / L of BH type reagent to the first physical and chemical reaction tank, stir and react for 30min, and then enter the second physical and chemical reaction tank; add hydrogen to the second reaction tank Adjust the pH to neutral with sodium oxide, then add 600 mg / L of defluorinating agent, stir and react, enter the coagulation reac...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap