Enhanced vapor injection variable-frequency air source heat pump hot water system and operation control method

An air source heat pump and hot water system technology, applied in heat pumps, refrigerators, refrigeration components, etc., can solve the problems of not being able to provide heat for the hot end, reduce discomfort, improve operating conditions, and increase total output heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

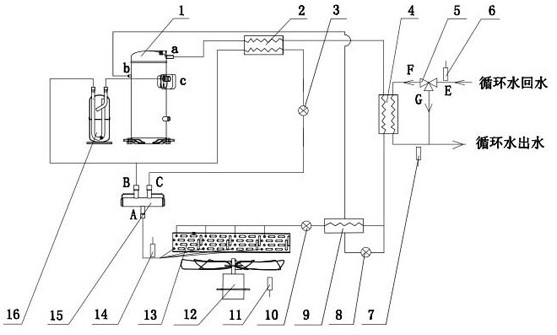

[0021] Such as figure 1 As shown, it is a variable frequency air source heat pump hot water system with air injection and enthalpy increase, which includes a compressor 1, a heat storage heat exchanger 2, a bypass electronic expansion valve 3, a refrigerant-water heat exchanger 4, and a three-way ratio Regulating valve 5, circulating water return temperature sensor 6, circulating water outlet temperature sensor 7, jet electronic expansion valve 8, economizer 9, main electronic expansion valve 10, outdoor ambient temperature sensor 11, outdoor unit fan 12, outdoor unit heat exchange Device 13, outdoor unit heat exchanger tube temperature sensor 14, three-way valve 15, ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com