Swing mechanism for driving part of machine tool to rotate

A technology of slewing mechanism and machine tool, which is applied in the direction of metal processing machinery parts, manufacturing tools, metal processing equipment, etc. It can solve the problems of increasing cost expenditure, occupying space, affecting positioning accuracy, etc., and achieves the effect of precisely controlling the rotation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

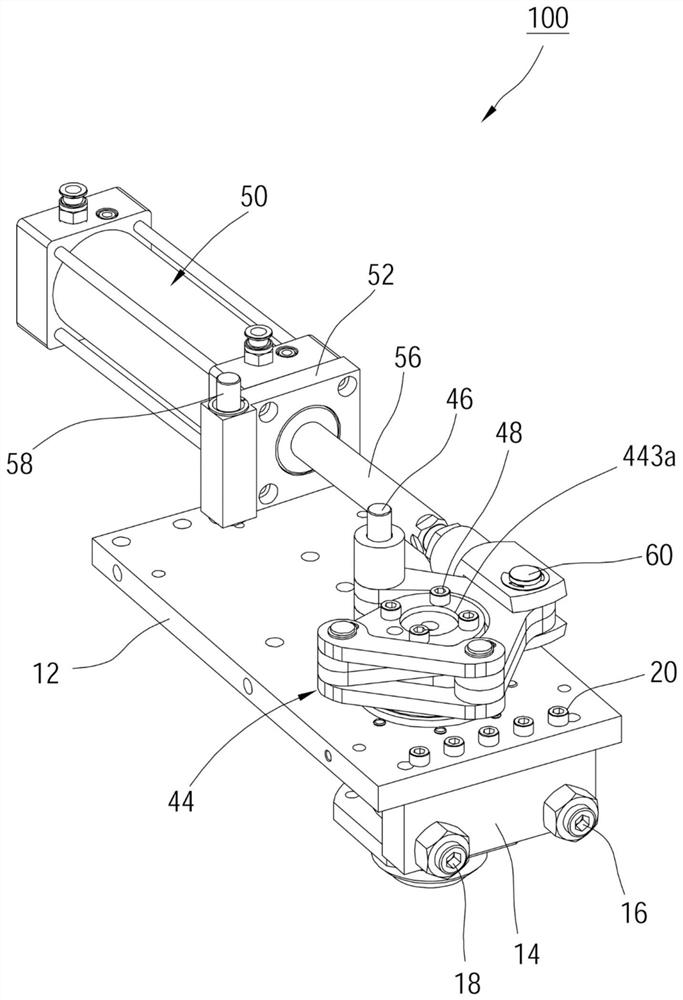

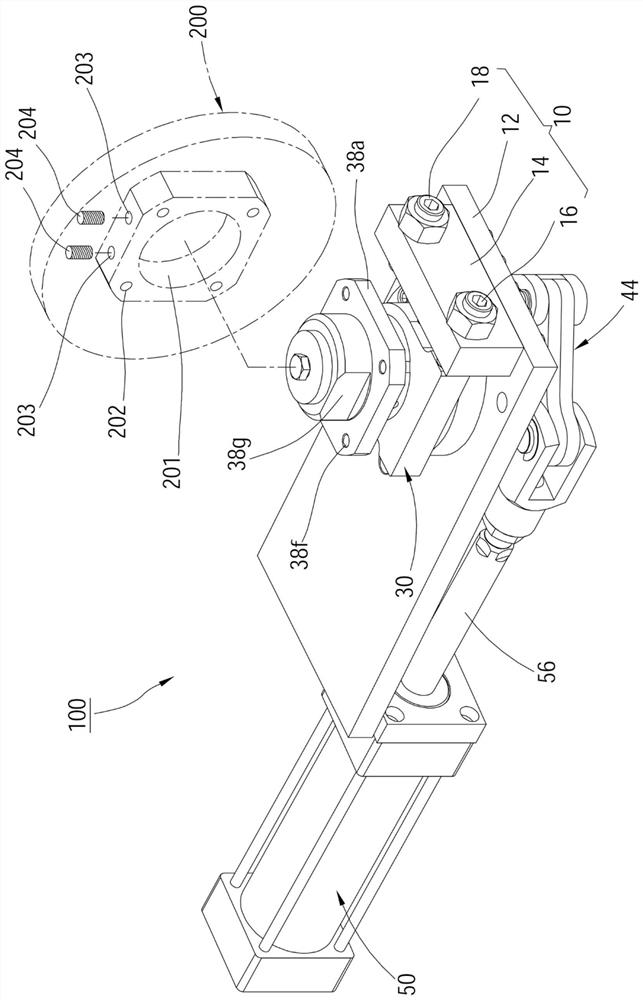

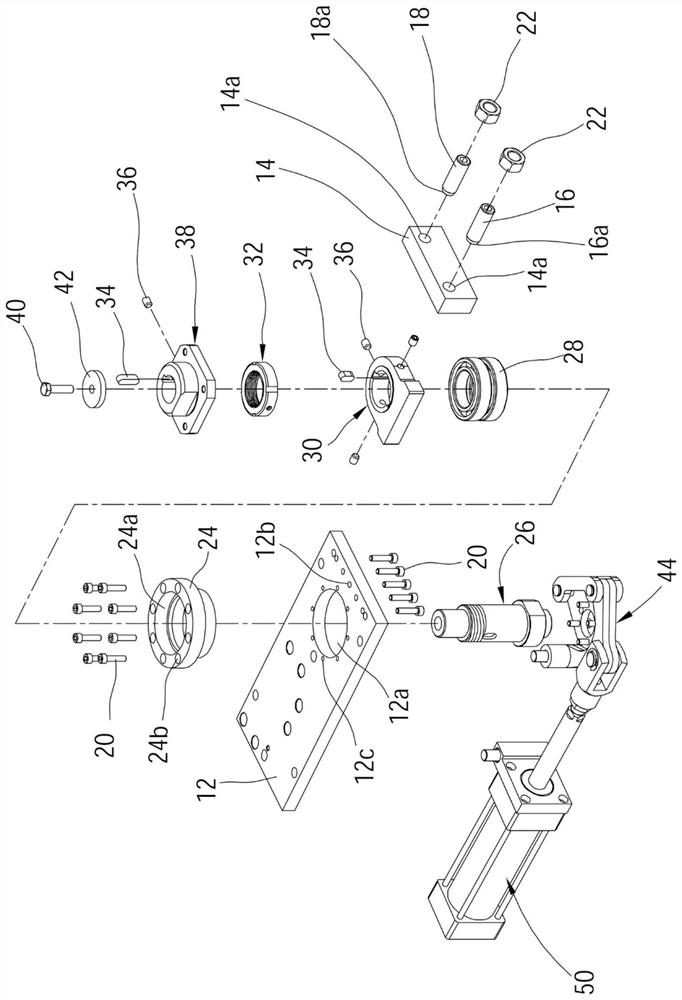

[0092] In order to illustrate the present invention more clearly, a preferred embodiment is given and described in detail with accompanying drawings as follows. Please refer to Figure 1 to Figure 4 As shown, the rotary mechanism 100 of a preferred embodiment of the present invention is used to drive the parts of the machine tool to rotate. The aforementioned parts are, for example, the tool changing arm of the automatic tool changing mechanism or a kind of changing plate, but not limited thereto. The rotary mechanism 100 of this embodiment includes a base 10 , a bearing seat 24 , a rotating shaft 26 , at least one bearing 28 , a block 30 , a locking nut 32 , a connecting seat 38 , a link mechanism 44 , and a driving mechanism 50 . Hereby explain one by one as follows.

[0093]The base 10 includes a solid rigid member 12 , a coupling block 14 , a first adjustment piece 16 and a second adjustment piece 18 . The rigid member 12 has a circular opening 12a, a plurality of throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com