Silk rereeling and pre-tightening device for textile processing

A technology of silk and pre-tensioning parts, applied in the direction of silk reeling, etc., can solve the problems of easily scattered reeled silk, waste of resources, inconvenient sorting and recycling of miscellaneous silk, etc., to prevent excessive vibration frequency, reduce processing costs, and facilitate recycling The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

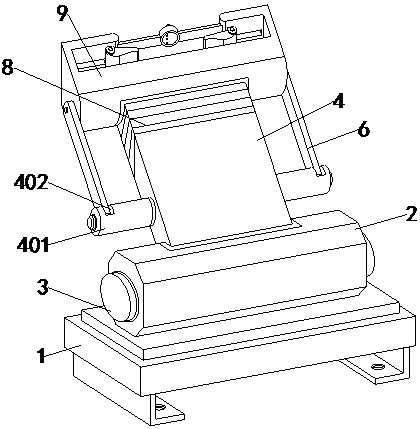

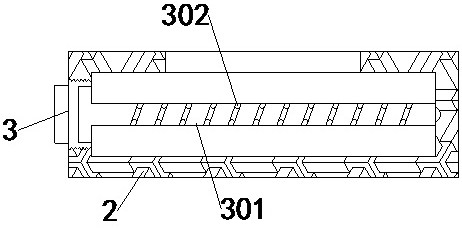

[0038] see Figure 1-Figure 12 , a spinning pretensioning device for textile processing silk, comprising a mounting support 1 and a collecting box 2, the collecting box 2 being installed on the top of the mounting support 1;

[0039] Specifically, first place the installation support 1 at the front end of the re-swing position of the silk, and install the installation support 1 and the re-swing equipment through bolts to maintain the stability of the installation support 1;

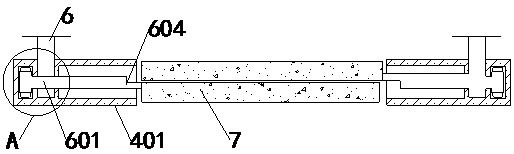

[0040] A receiving tube 4 is installed at the rear upper corner of the collection box 2, and the left and right sides of the receiving tube 4 are fixedly installed with symmetrically arranged subsidiary side cylinders 401, and the rear side of the subsidiary side cylinder 401 is provided with a turning groove 402, And inside the attached side cylinder 401 and outside the rotating groove 402, there is a shock absorbing groove 5, and the inner wall of the shock absorbing groove 5 is fixed with a butt plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com