Device and method for sinking aid of steel pipe pile in hard sandy soil layer using high pressure water jet

A high-pressure water jet, steel pipe pile technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve problems such as use defects, and achieve the effect of improving efficiency, simple operation and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

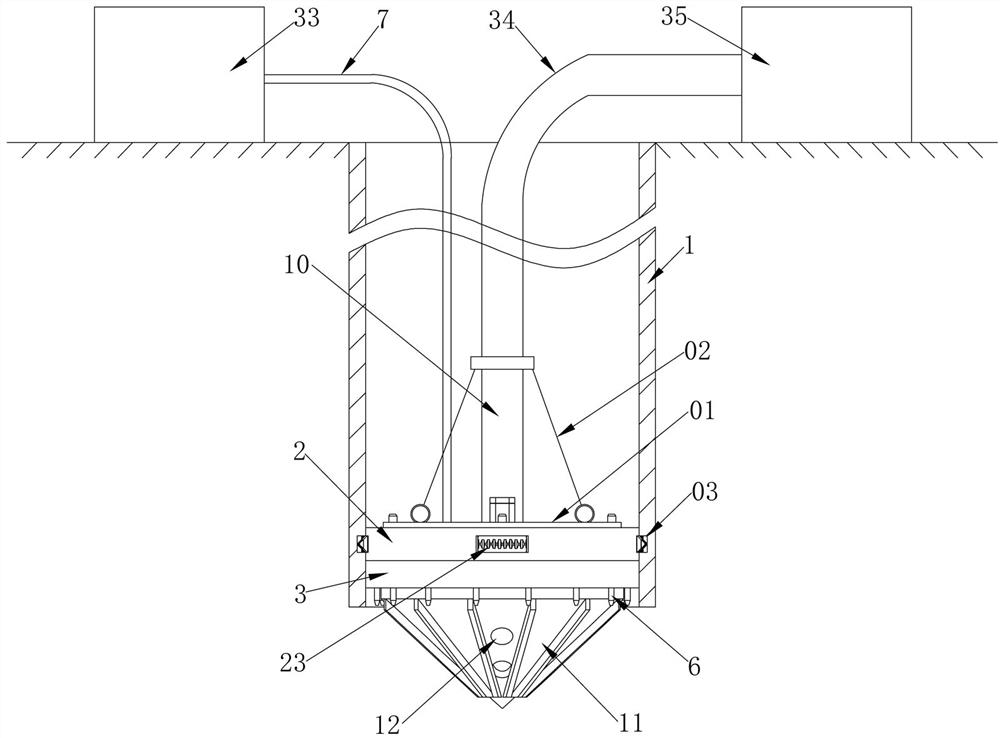

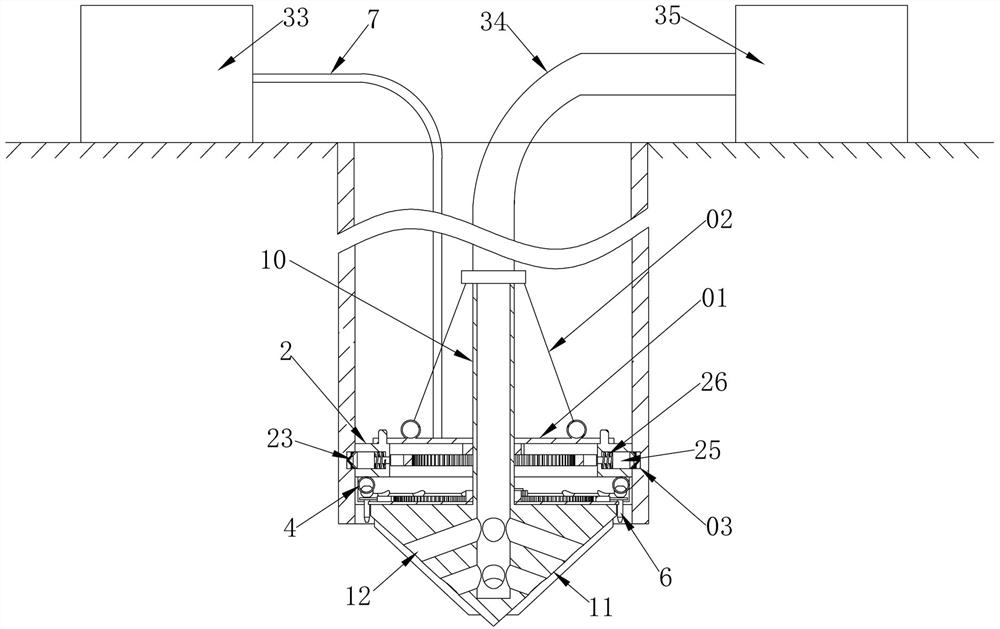

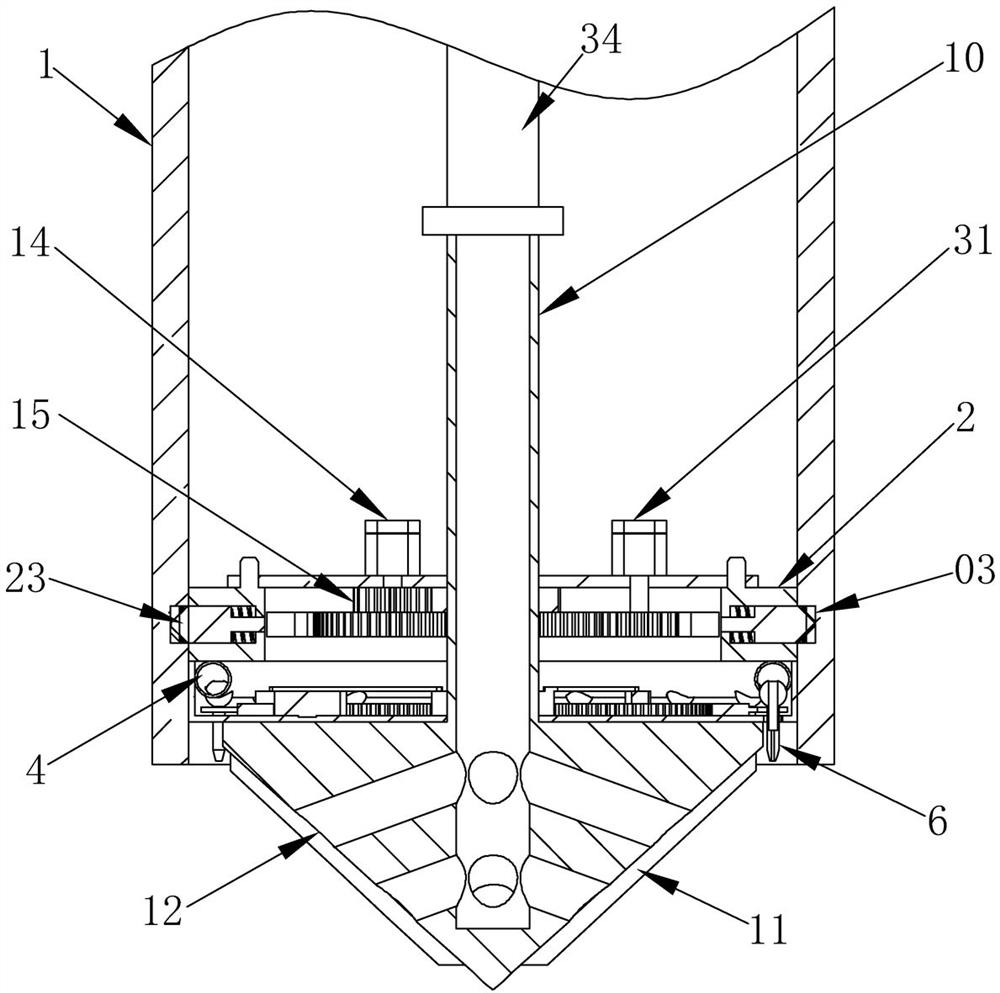

[0033] Embodiment 1, the present invention is a settling aid device for steel pipe piles in hard sandy soil layers using high-pressure water jets, including steel pipe piles 1, and the steel pipe piles 1 are vertically placed in the pre-drilled embedding holes on the ground by a crane, The bottom end inside the steel pipe pile 1 is coaxially and detachably installed with a positioning ring 2 with a top bolt fixed to the top plate 01. The outer diameter of the positioning ring 2 is slightly smaller than the inner diameter of the steel pipe pile 1, so that the positioning ring 2 can be placed in the The steel pipe pile 1 moves up and down coaxially. When installing the positioning ring 2, it can be inserted from one end of the steel pipe pile 1, and then the positioning ring 2 is fixed on the inner wall of the steel pipe pile 1. The top of the top plate 01 is fixedly connected There is a wire rope 02, and the other end of the wire rope 02 is connected with the crane. When the ste...

Embodiment 2

[0036] Embodiment 2, on the basis of Embodiment 1, the water pumping pipe 10 is coaxially fixed with a water pumping pipe gear 13 located below the top plate 01. The water pumping pipe gear 13 can rotate synchronously with the water pumping pipe 10. The top of the 01 is fixedly installed with a pumping pipe motor 14, which is connected to the power supply and control switch on the ground through wires. When the motor 14 rotates, the pumping pipe gear 13 can be driven to rotate through the pumping drive gear 15, thereby driving the sinking drill bit 11 to rotate.

Embodiment 3

[0037] Embodiment 3, on the basis of Embodiment 2, the inner surface of the sprinkler ring 8 is coaxially fixed with a sprinkler ring gear 16, and the sprinkler ring gear 16 can rotate synchronously with the sprinkler ring 8. A sprinkler gear 17 meshing with the sprinkler ring gear 16 is rotatably installed on the bottom surface of the water pump. When the sprinkler gear 17 rotates, it can drive the sprinkler ring gear 16 to rotate. 18. When the water pumping pipe 10 rotates, it can drive the spray head driving ring 18 to rotate synchronously. The spray head driving ring 18 is fixedly connected with the external tooth circular arc rack 19 and the internal tooth circular arc which can be respectively meshed with the spray head gear 17 through the connecting rod 04. rack 20;

[0038] as attached Figure 9 As shown in the figure, if the water pumping pipe 10 is rotated clockwise, the nozzle drive ring 18 can drive the externally toothed circular arc rack 19 and the internal toot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com