Mounting method of fabricated wall

An installation method and assembly technology, applied in the processing of walls, building materials, construction, etc., can solve the problems of increased labor costs and low installation accuracy, and achieve the effect of improving installation accuracy and high-precision installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

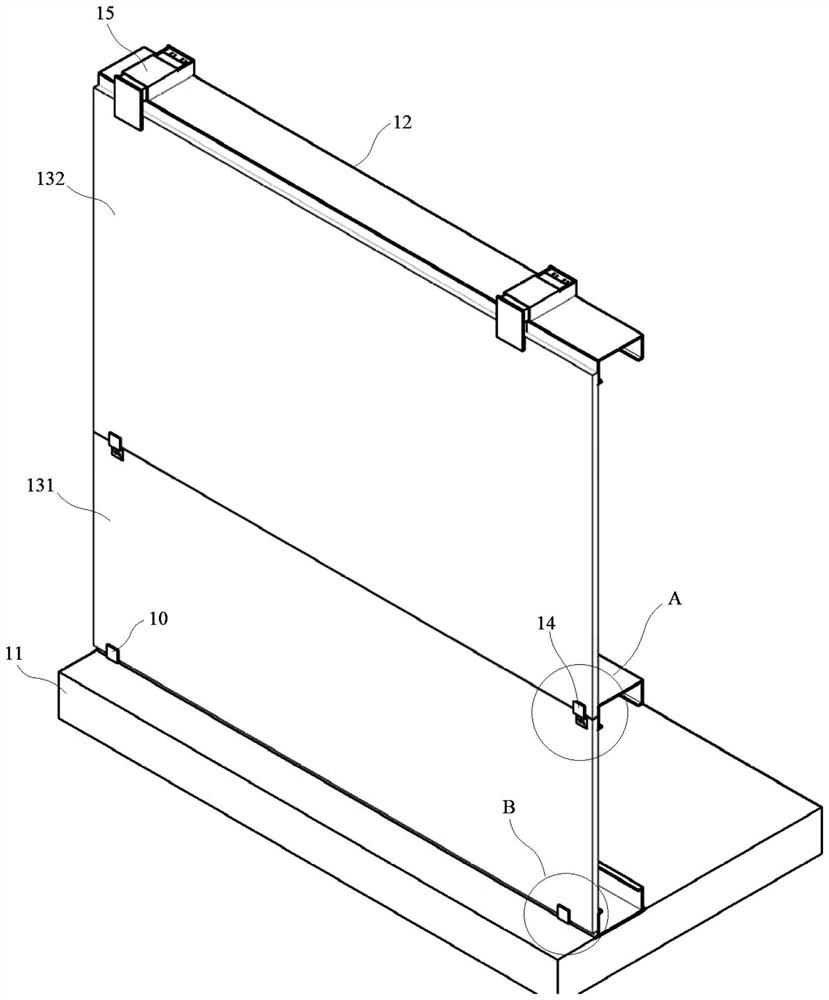

[0038] Embodiment 1: A method for installing a prefabricated wall, the wall includes a base layer 11, a support frame 12 installed on the base layer 11, a lower wall panel 131 and an upper wall panel 132 located outside the support frame 12;

[0039] The installation method includes the following steps:

[0040] Step 1, installing at least two starting supports 10 at the bottom of the supporting frame 12 at intervals;

[0041] Step 2, embed the lower end of the lower wallboard 131 into the starting support 10;

[0042] Step 3, connect the lower wall panel 131 with the crossbeam of the supporting frame 12 through a mounting clip 15;

[0043] Step 4, fixing the lower wall panel 131 with the support frame 12 by nailing;

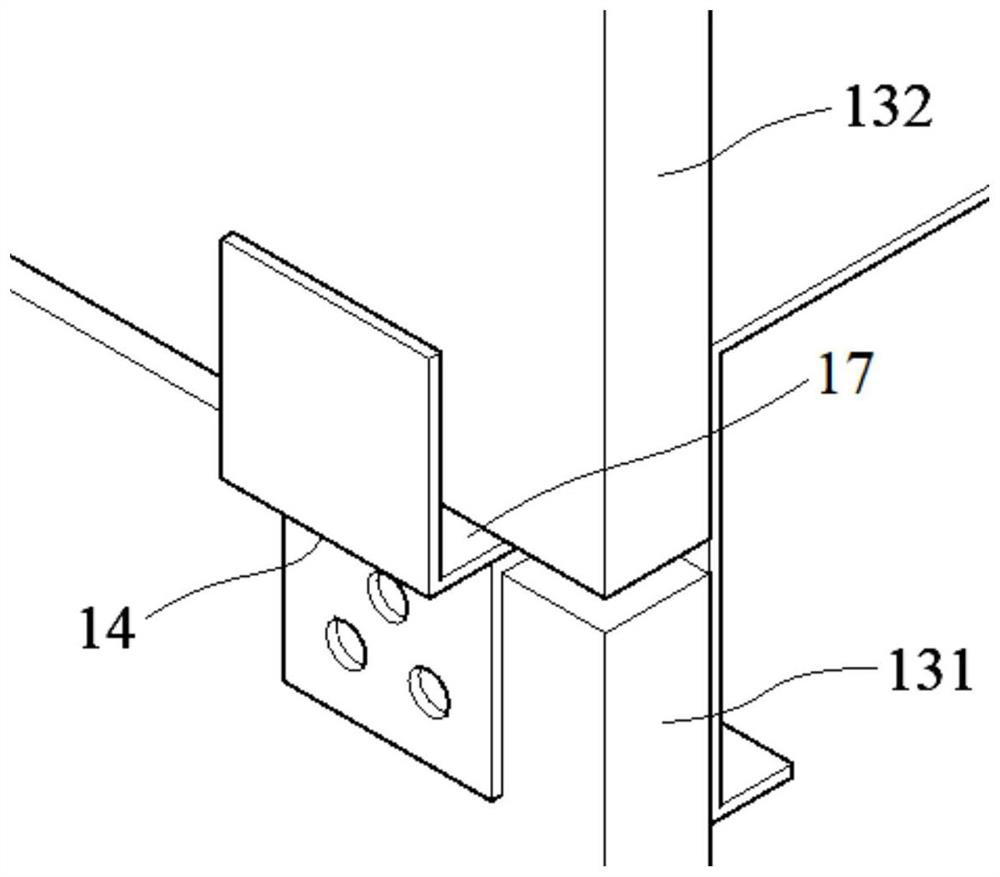

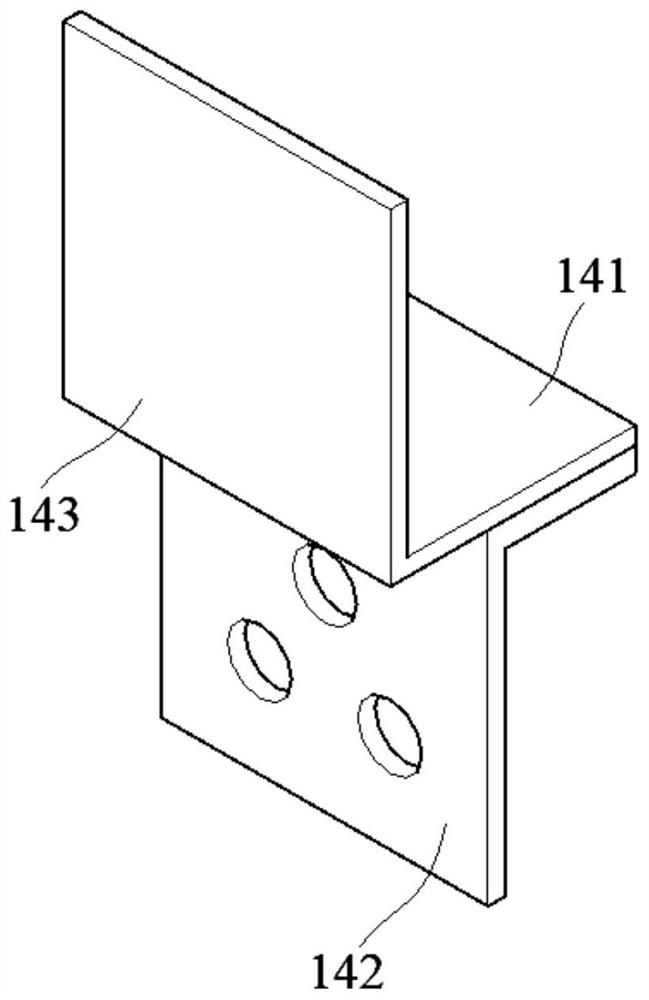

[0044] Step 5, install at least two transitional supports 14 at intervals on the upper part of the lower wall panel 131;

[0045] Step 6, embed the lower end of the upper wallboard 132 into the transition support 14;

[0046] Step 7. Connect the upper wall p...

Embodiment 2

[0053] Embodiment 2: A method for installing a prefabricated wall, the wall includes a base layer 11, a support frame 12 installed on the base layer 11, a lower wall panel 131 and an upper wall panel 132 located outside the support frame 12;

[0054] The installation method includes the following steps:

[0055] Step 1, installing at least two starting supports 10 at the bottom of the supporting frame 12 at intervals;

[0056] Step 2, embed the lower end of the lower wallboard 131 into the starting support 10;

[0057] Step 3, connect the lower wall panel 131 with the crossbeam of the supporting frame 12 through a mounting clip 15;

[0058] Step 4, fixing the lower wall panel 131 with the support frame 12 by nailing;

[0059] Step 5, install at least two transitional supports 14 at intervals on the upper part of the lower wall panel 131;

[0060] Step 6, embed the lower end of the upper wallboard 132 into the transition support 14;

[0061] Step 7. Connect the upper wall p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com