Curved surface type automobile glass physical performance testing device

A technology for automotive glass and physical properties, applied in the field of testing devices for physical properties of curved automotive glass, can solve problems such as inability to adjust impact strength, inaccurate test results, displacement or offset of curved automotive glass, and achieve increased stability in use and safety, increase the safety and stability of use, and improve the efficiency and convenience of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

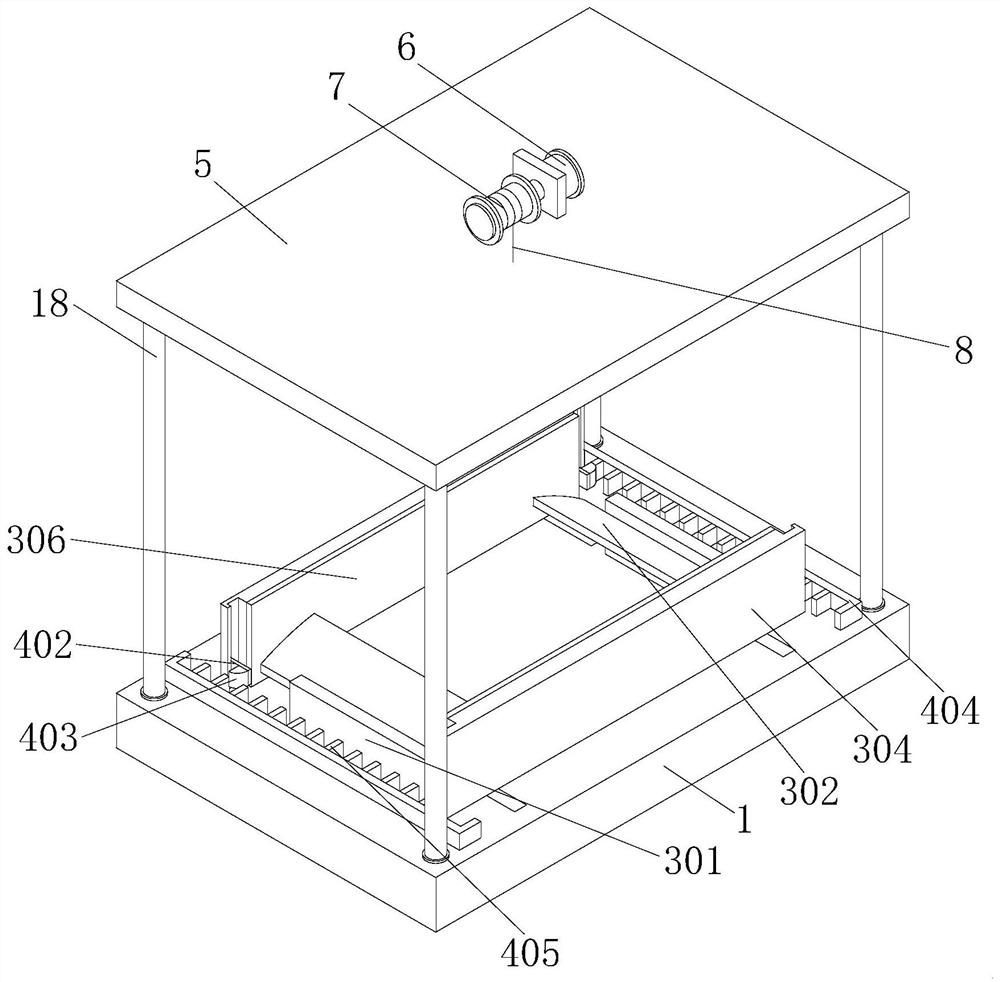

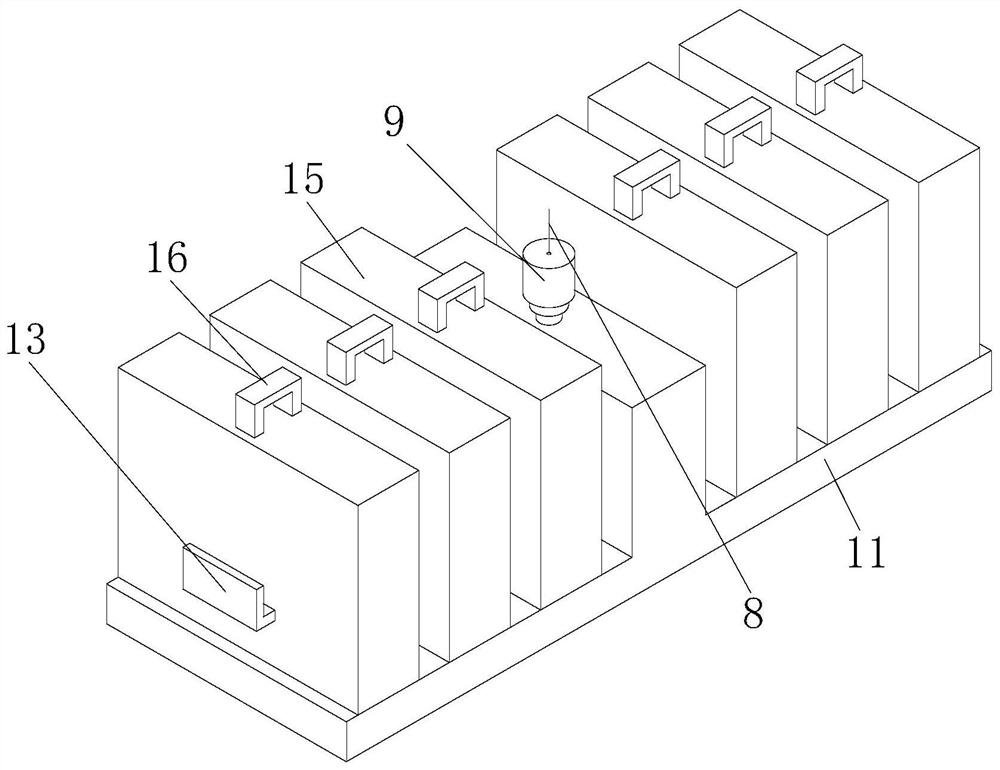

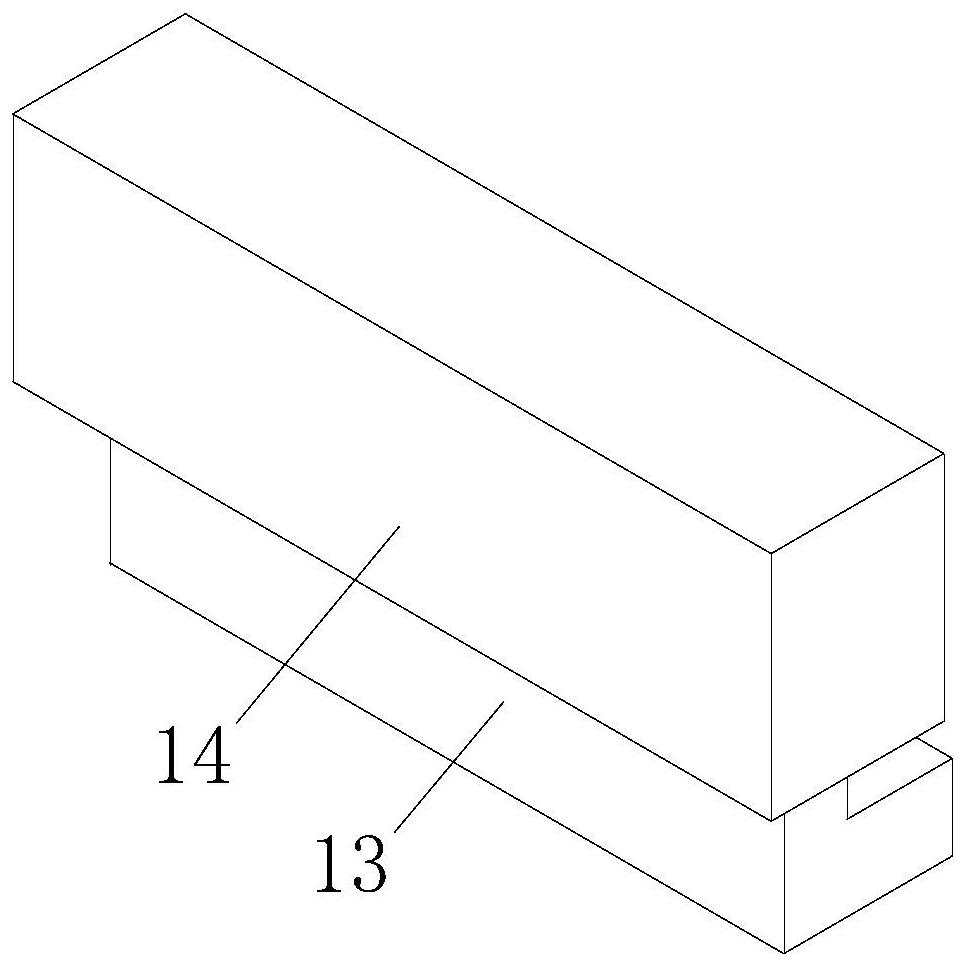

[0039] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

[0040] Such as Figure 1-Figure 12 As shown, a curved surface type automotive glass physical performance testing device includes a fixed base 1, a buffer protection component 2 is installed on the bottom end surface of the fixed base 1, and an automatic clamping and limiting component 3 is installed on the top surface of the fixed base 1, The top surface of the automatic clamping limit component 3 and the fixed base 1 is equipped with an automatic clamping and fixing component 4, the top surface of the fixed base 1 is welded and fixed with a support rod 18, and the top of the support rod 18 is welded and fixed with a fixed top plate 5;

[0041] The buffer protection assembly 2 includes a damping cylinder 201, a support base 202 and a sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com