Method for removing dry film on copper layer of circuit board

A technology for circuit boards and circuit board substrates, applied in printed circuits, printed circuit manufacturing, electrical components, etc., can solve problems such as copper surface oxidation, reduce PCB quality, accelerate copper surface oxidation speed and oxidation area, and avoid excessive Oxidation, the effect of reducing the oxidation rate

Active Publication Date: 2021-12-21

JIANDING HUBEI ELECTRONICS CO LTD

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] NaOH will react with the copper surface of the PCB to produce Cu(OH) 2 , that will cause the copper surface to oxidize; furthermore, the total time required for NaOH to remove the dry film is longer (the total time for soaking

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to view more

Login to view more PUM

Login to view more

Login to view more Abstract

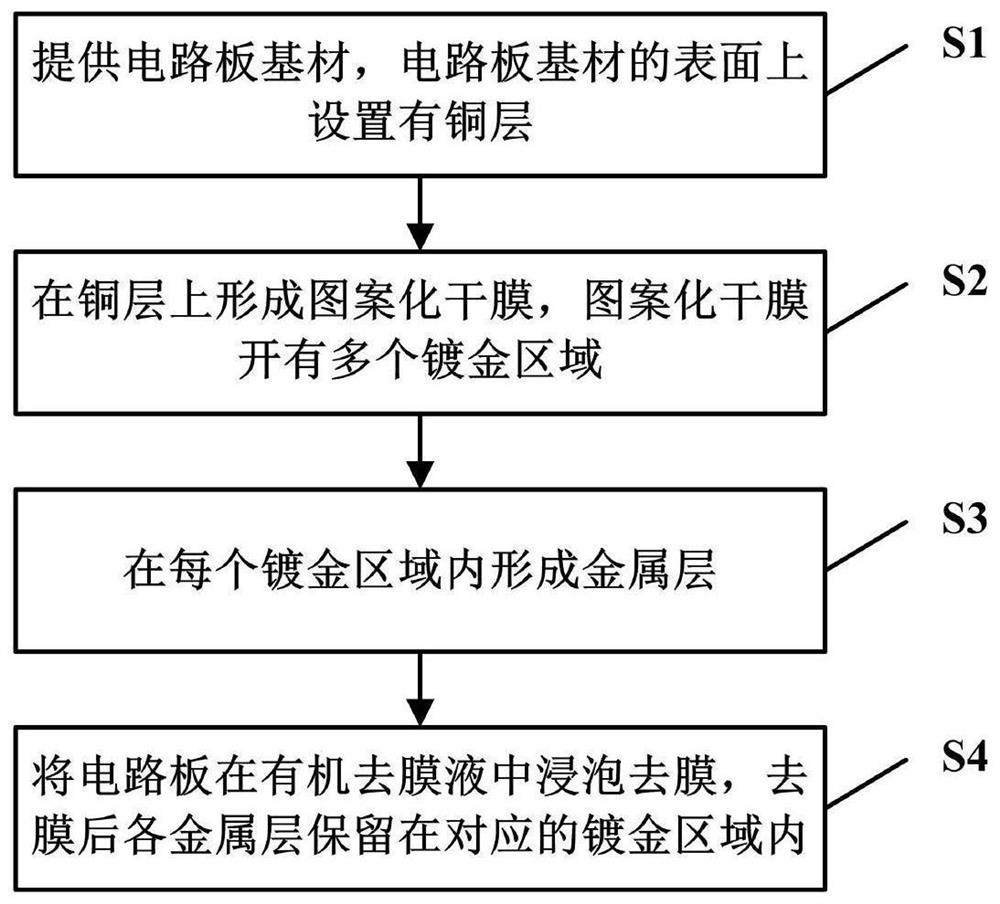

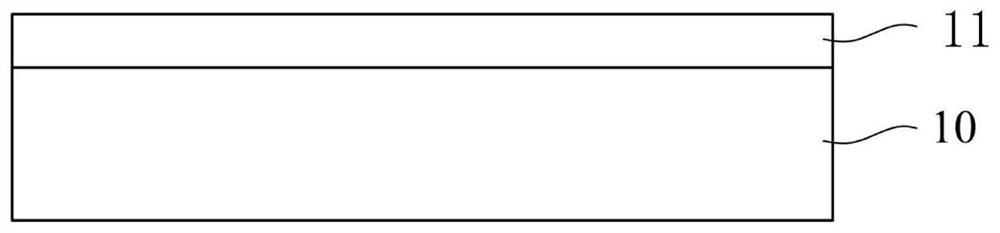

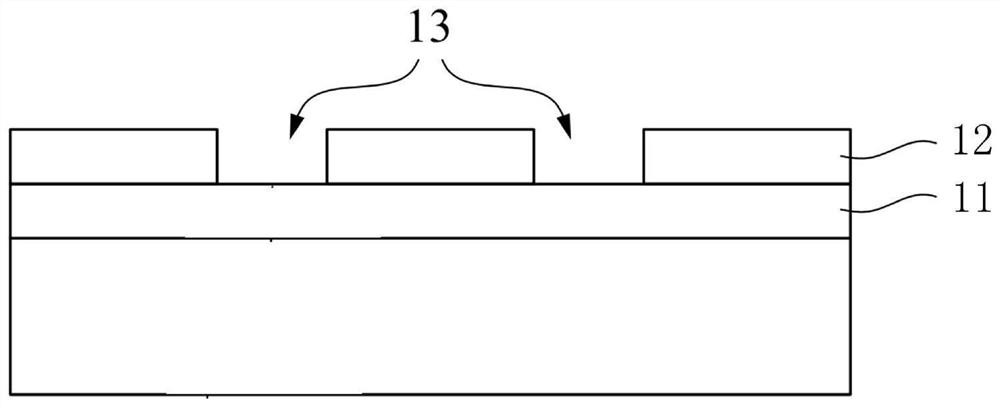

The invention discloses a method for removing a dry film on a copper layer of a circuit board, and relates to the field of circuit board manufacturing. The method comprises the following steps: providing a circuit board substrate, wherein a copper layer is arranged on the surface of the circuit board substrate; forming a dry film with a plurality of openings on the copper layer, wherein the copper layer area exposed in each opening is a gold plating area; forming a metal layer in each gold plating area; making the circuit board soaked and defilmed in an organic defilming solution at the temperature of 50-60 DEG C, wherein the organic defilming solution comprises sodium hydroxide, an interfacial agent, a copper protection agent and a regenerant; and after soaking is completed, the oxidation rate of the copper surface of the copper layer being 0.13%-1.25%.

Description

technical field [0001] The invention relates to the field of circuit board manufacturing, in particular to a method for removing a dry film on a copper layer of a circuit board. Background technique [0002] PCB (Printed Circuit Board, printed circuit board) is a circuit board formed by making electronic wiring connecting circuit parts into graphics according to circuit design, and then reproducing electronic conductors on insulators through specific mechanical processing and processing. The main purpose is to make the electronic components arranged on the circuit board function through the circuit on the circuit board. [0003] With the high performance of electronic products, the surface treatment of PCB will use gold plating or gold plating with excellent performance. In order to protect the substrate of the PCB, before gold plating or gold plating, a dry film is usually used to cover the surface of the circuit board substrate and selectively expose the copper surface to...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): H05K3/18

CPCH05K3/184H05K2203/0562Y02P10/20

Inventor 任念雷志红

Owner JIANDING HUBEI ELECTRONICS CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap