Bottle toppling and conveying device for medicine bottles

A conveying device and medicine bottle technology, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of fragile glass material, low stability requirements, and unsuitable oral liquid medicine bottles, etc. The effect of high weight and low structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be explained more clearly and completely through the description of preferred embodiments of the present invention in conjunction with the accompanying drawings.

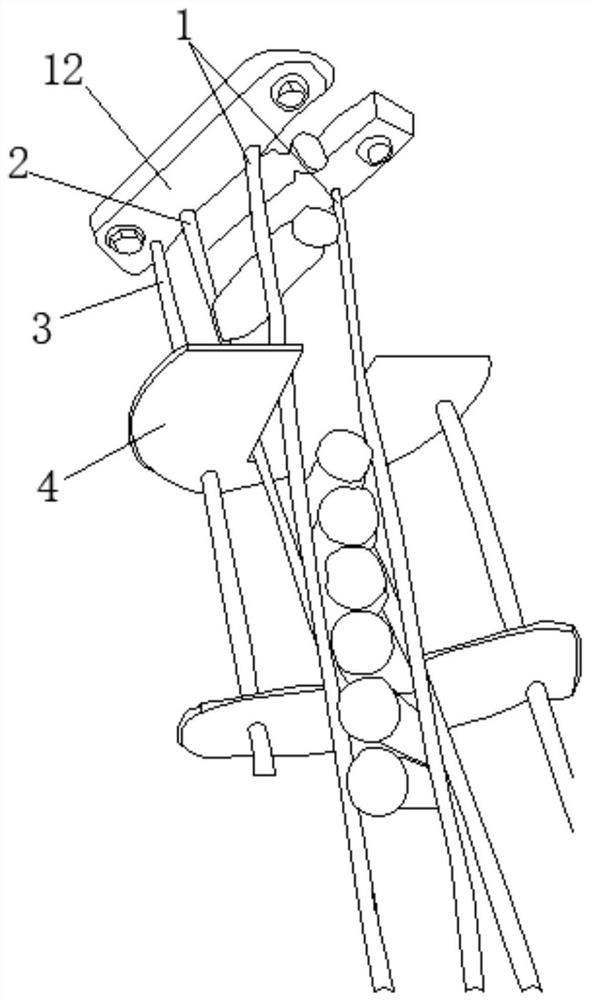

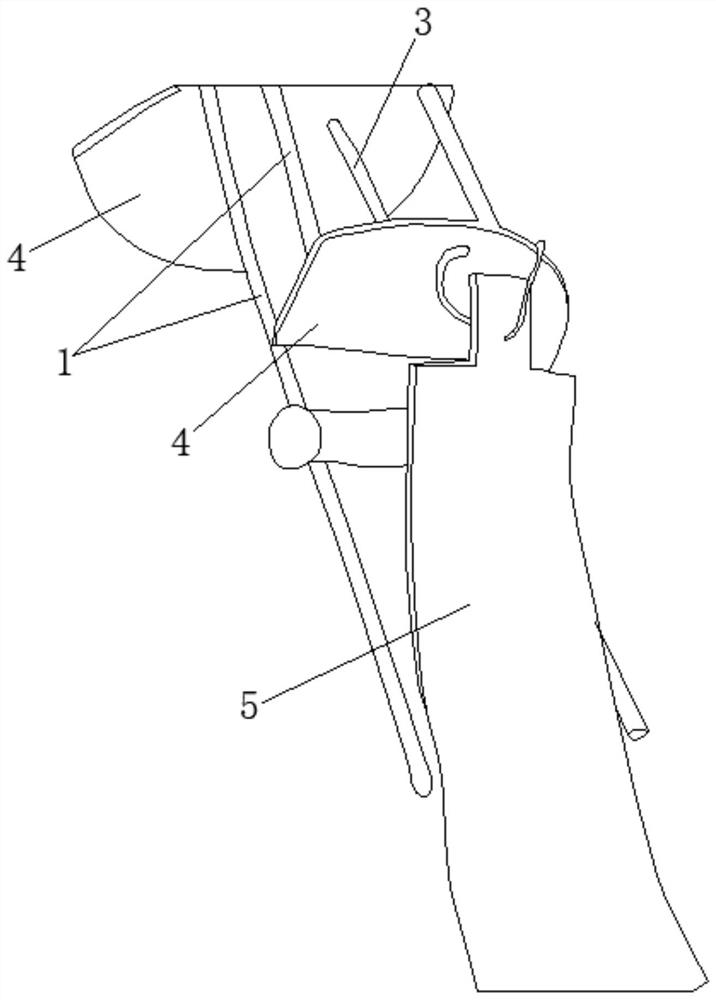

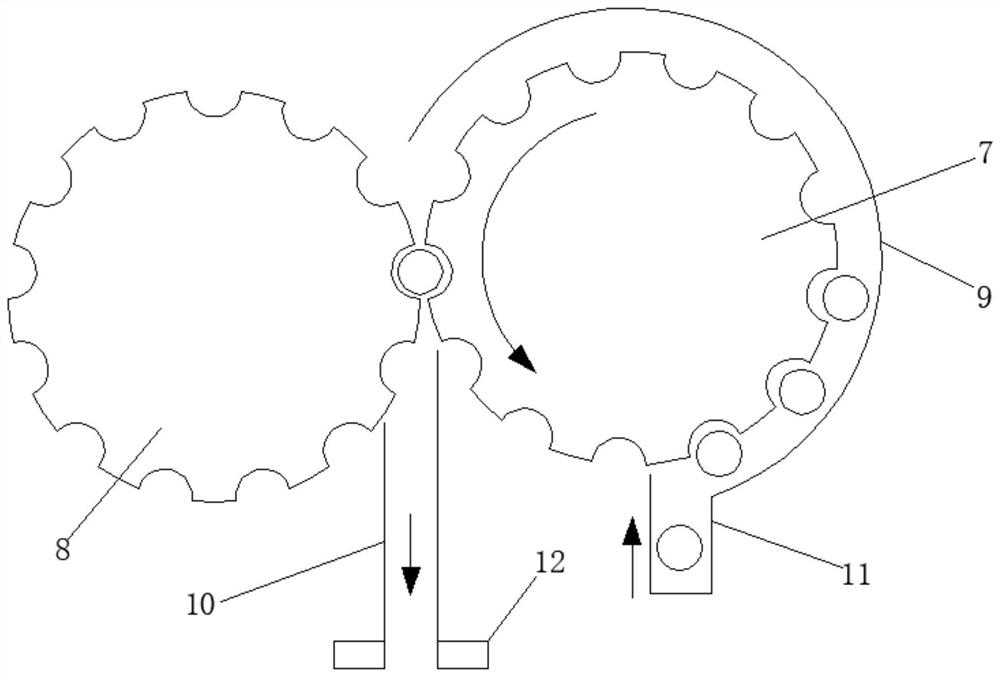

[0018] Such as figure 1 As shown, the bottle-inverting conveying device of the preferred embodiment of the present invention includes two fixed blocks 12, two stop bars 1 and at least one bottle-supporting bar 2 are welded on the two fixed blocks 12, preferably 2 A bottle holder bar 2. The two limit rods 1 collide with the body of the bottle, and the bottle bearing rod 2 collides with the bottom of the bottle. When there is power to send bottles one by one between the two limiting rods 1 continuously, the medicine bottles between the two limiting rods 1 can move along the length direction of the limiting rods 1 .

[0019] The state of the medicine bottle is constantly changed by the two position-limiting rods 1, so that the medicine bottle is gradually in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com