Sewage treatment equipment based on rotary uniform stirring of water treatment agent

A sewage treatment equipment and water treatment agent technology, applied in water/sewage treatment equipment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as reduced service life, filter corrosion, and single filter structure , to achieve the effect of increasing the service life and improving the cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

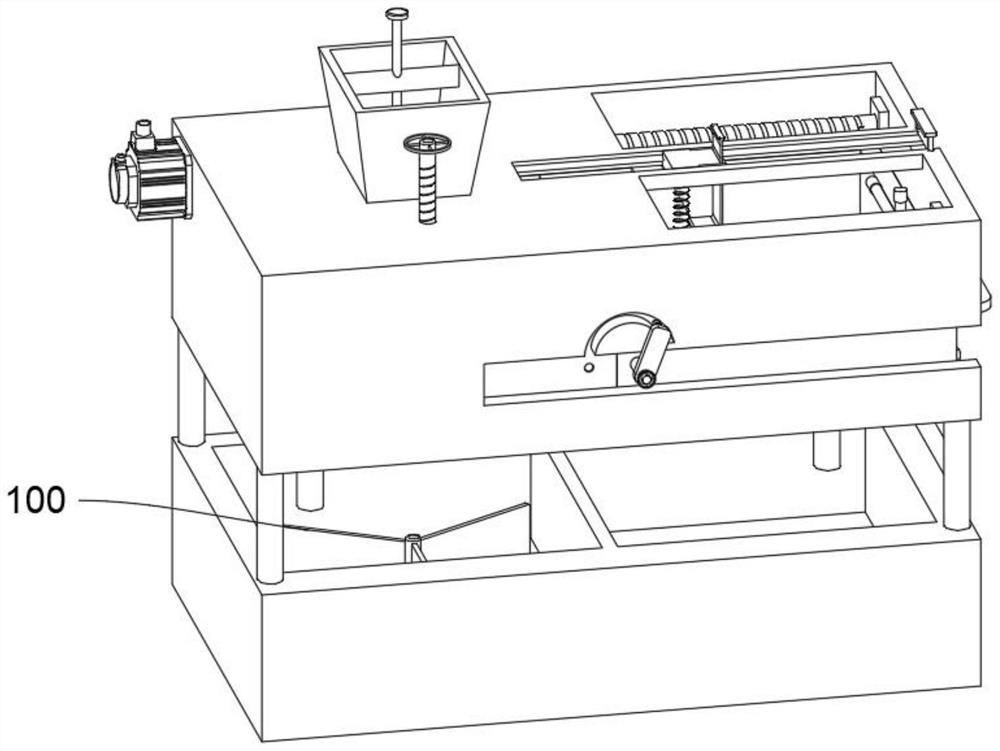

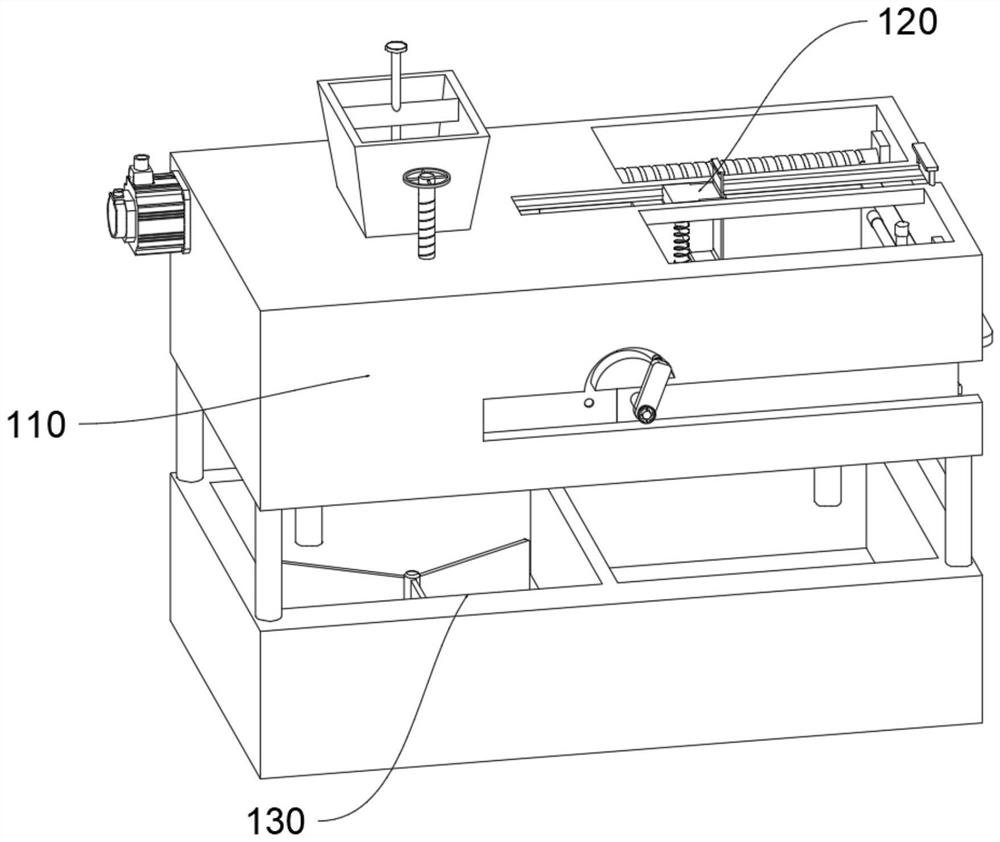

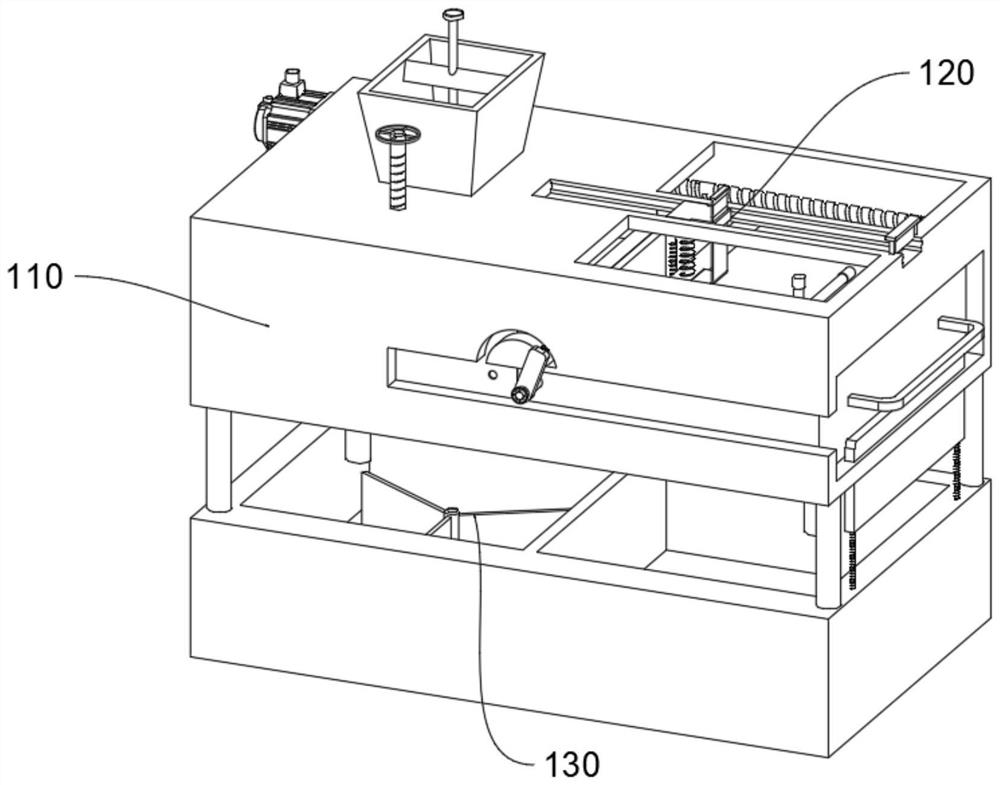

[0044] see Figure 1-Figure 9 As shown, the purpose of this embodiment is to provide a sewage treatment equipment based on a rotating water treatment agent uniformly stirred, including a sewage treatment device 100, and the sewage treatment device 100 at least includes:

[0045] Filter body 110, filter body 110 comprises casing 111, and the upper surface of casing 111 is communicated with liquid inlet bin 112, and the inside of casing 111 is provided with filter bin 113, and the inside of filter bin 113 is connected with filter plate 1134, the inner wall upper side of casing 111 A driving assembly 114 is provided, and the driving assembly 114 includes a driving screw 1141 and a cross bar 1146. The surfaces of the driving screw 1141 and the cross bar 1146 are connected with guide rods 1142, and the bottoms of the guide rods 1142 are provided with guide springs 1143 , the bottom of the guide spring 1143 is equipped with a magnetic plate 1144, one end of the filter chamber 113 is...

Embodiment 2

[0056] In order to facilitate simultaneous removal of the filter chamber 113 and the cleaning chamber 115, the difference between this embodiment and Embodiment 1 is that please refer to Figure 7 with Figure 10 Shown:

[0057]Wherein, the side wall of the housing 111 is provided with an arc opening 1112, one end of the surface of the filter chamber 113 is provided with a fixing hole 1133, and the side wall of the cleaning chamber 115 is equipped with a connection assembly 117, the connection assembly 117 includes a connection shaft 1171, and the connection shaft 1171 runs through the casing 111 communicates with the cleaning chamber 115, the surface of the connecting shaft 1171 is rotatably connected with a fixed plate 1172, and one end of the surface of the fixed plate 1172 is equipped with a connecting buckle 1174 through a connecting spring 1173, and the connecting spring 1173 can slide along the inside of the arc mouth 1112, and the connecting buckle 1174 is connected a...

Embodiment 3

[0059] In order to improve the practical effect of the end chamber 1114, the difference between this embodiment and Embodiment 1 is that, please refer to Figure 11 Shown:

[0060] Wherein, the inner side of the end chamber 1114 is provided with an upper plate 122, the side ends of the upper plate 122 are provided with side rods 1221, the side rods 1221 are plugged and fixed with the housing 111, and a baffle plate 1222 is installed between the side rods 1221, wherein The baffle plate 1222 can block the inside of the end cavity 1114, that is, close the end cavity 1114, prevent the cleaning slider 121 from sliding out of the end cavity 1114, and at the same time, when the cleaning slider 121 needs to be moved out of the cleaning plate 1212, it can be moved upward. Pull out the upper plate 122 , that is, the side bar 1221 and its baffle 1222 leave the interior of the end chamber 1114 , and the cleaning slider 121 can slide out along the end chamber 1114 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com