Special bleeding-preventing zero-VOC color paste for multicolor paint and preparation method of color paste

A multi-color paint and color paste technology, applied in the direction of multi-color effect paint, pigment paste, etc., can solve the problems of poor color particle stability, air pollution, inconsistent effect, etc., achieve high environmental protection, good color retention, prevent The effect of color bleeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

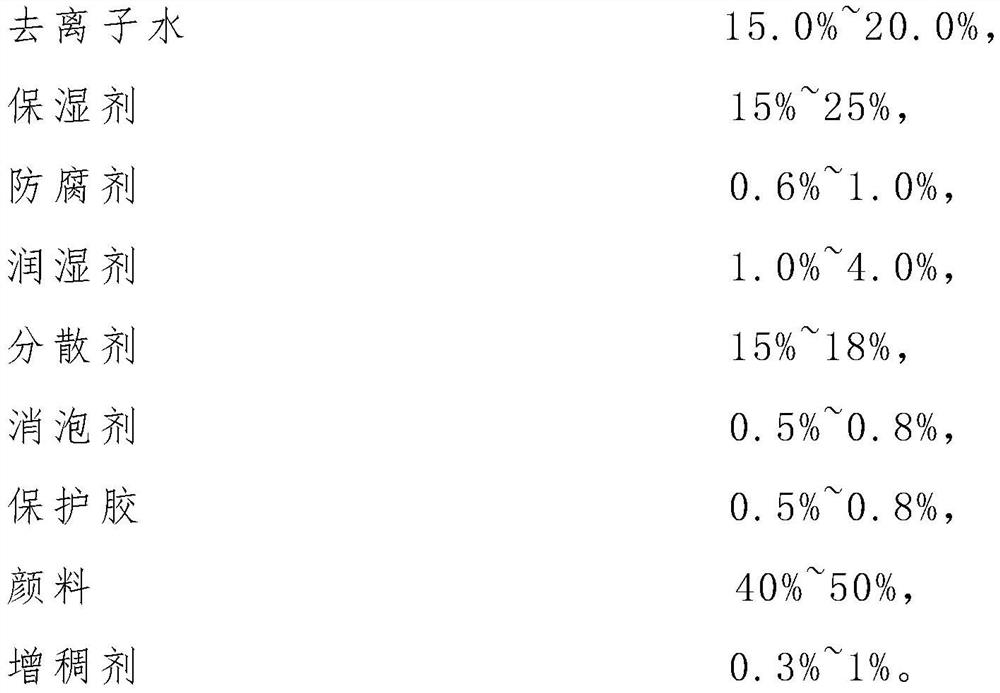

[0035] A method for preparing anti-bleeding and zero-VOC colorant specially used for colorful paints. The specific steps are as follows: first add deionized water into the reaction kettle, and then add humectants, preservatives, wetting agents, dispersants, and defoamers to disperse After 5 minutes, put in protective glue, adjust the pigment dispersion speed to 1000-1500 rpm, and disperse for 15-20 minutes to obtain a slurry dispersion; then use a pump to input the slurry dispersion into a sand mill for grinding, and the grinding speed Adjust to 800-1000 rpm, grind and disperse for 3-5 times, stop grinding until the slurry fineness is less than 5 microns, adjust the viscosity range to 70-90KU, filter and pack.

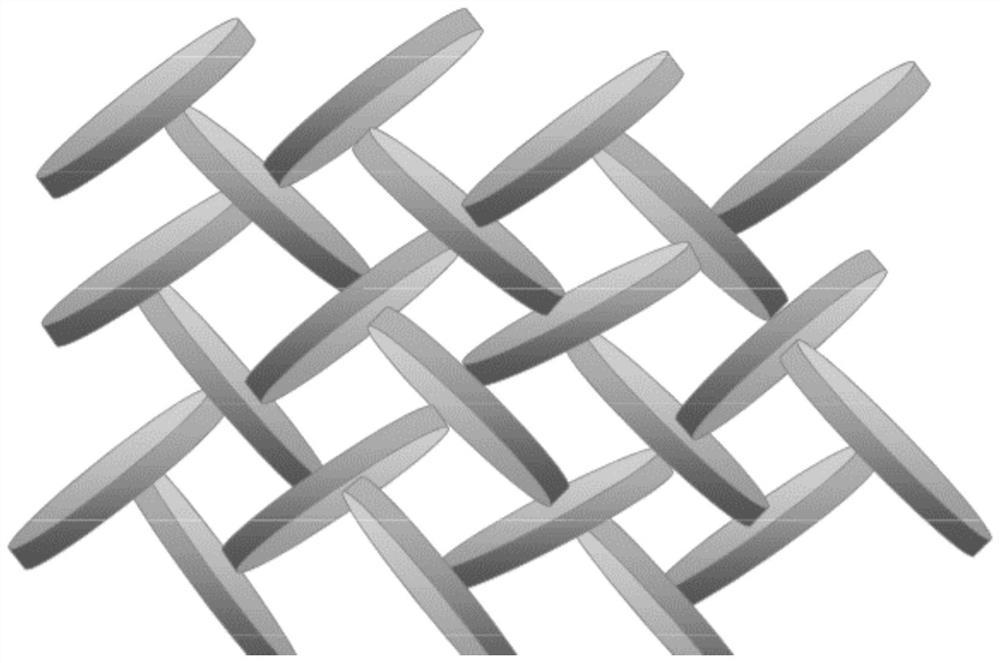

[0036] The present invention uses a modified aluminum-magnesium silicate or a modified sodium-magnesium-lithium silicate as a protective glue, which can form a potential isolation with deionized water and form a "card house structure", such as figure 1 As shown, the ad...

Embodiment 1

[0046]

Embodiment 2

[0048]

[0049]

[0050] The preparation method of embodiment 1 and embodiment 2, concrete steps are as follows: first add deionized water in the reactor, then add humectant, preservative, wetting agent, dispersant, antifoaming agent and disperse for 5 minutes, then put into Protective glue and pigment dispersion speed adjusted to 1000-1500 rpm, dispersed for 15-20 minutes to obtain a slurry dispersion; then use a pump to input the slurry dispersion into a sand mill for grinding, and adjust the grinding speed to 800-1000 rpm Grind and disperse 3-5 times per minute, stop grinding until the slurry fineness is less than 5 microns, adjust the viscosity range to 70-90KU, filter and pack.

[0051] The concrete performance of embodiment 1 and embodiment 2 is as table 1:

[0052] Table 1

[0053]

[0054] It can be known from the above table that the color paste of the present invention has excellent environmental protection and good anti-bleeding ability when applied to mul...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap