Cement stabilized macadam processing method

A technology of cement-stabilized crushed stone and a processing method, which is applied in the directions of roads, buildings, road repair, etc., can solve problems affecting asphalt roadbed, cement-stabilized crushed stone base cracks, asphalt roadbed cracks, etc., and achieve the effect of increasing service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

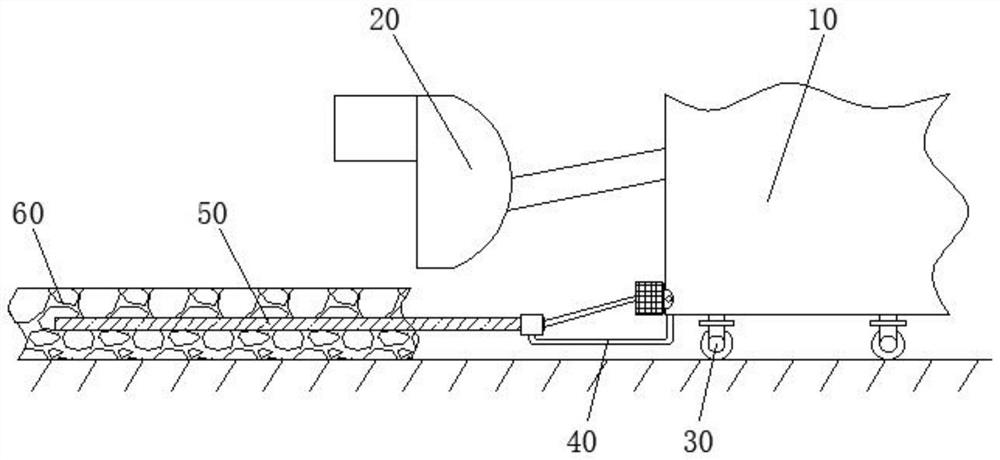

[0030] Such as figure 1 Shown, a kind of cement stabilized crushed stone processing method described in the present embodiment comprises the following steps:

[0031] S1, calculate the mixing ratio of the cement-stabilized gravel mixture, and stir and mix the cement-stabilized gravel mixture;

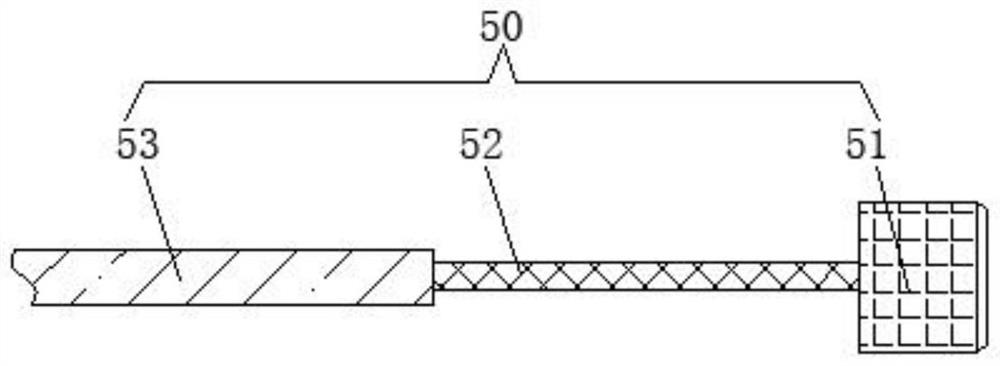

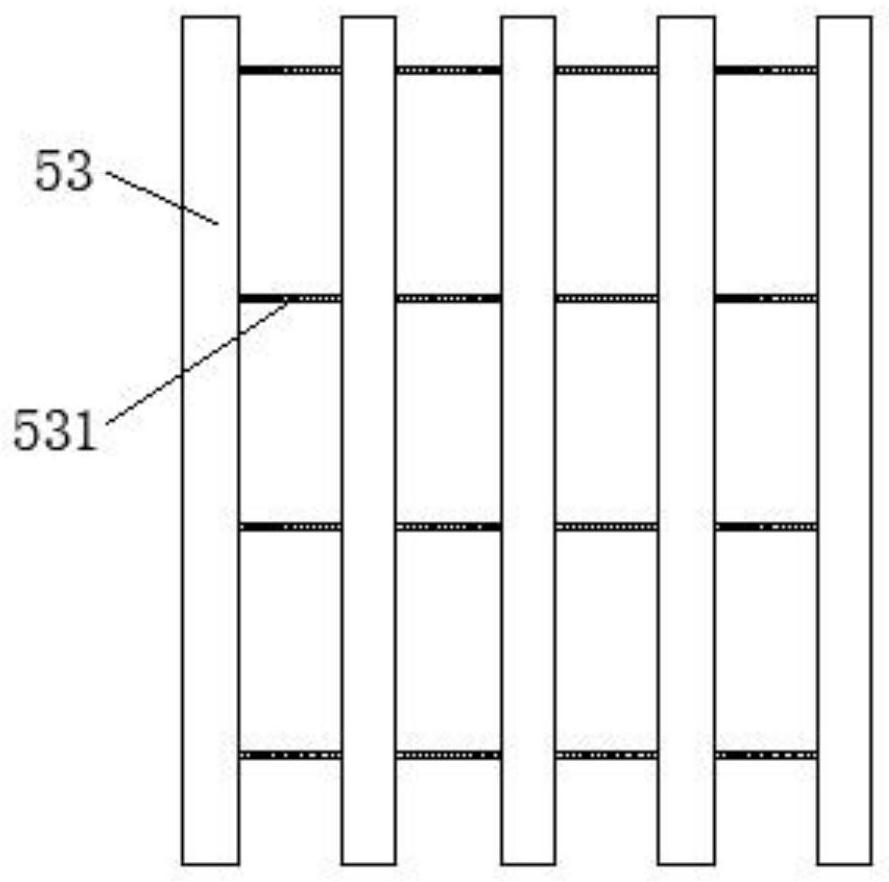

[0032] S2. Lay the cement-stabilized gravel mixture layer 60 on the roadbed. During the laying process, the vibrating member 50 vibrates the cement-stabilized gravel mixture, and the vibrating member moves along with the laying position of the cement-stabilized gravel mixture;

[0033] S3, after the cement-stabilized gravel mixture is vibrated by the vibrating member 50, the cement-stabilized gravel mixture layer 60 is then rolled;

[0034] S4. Maintain the cement-stabilized gravel mixture layer 60 until the strength of the cement-stabilized gravel mixture layer 60 is no less than 3.5 MPa.

[0035] This method can make the material filling between the gravel skeleton inside the cement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com