Non-uniform-rigidity holding handle structure and manufacturing method

A manufacturing method and non-uniform technology, applied in manufacturing tools, manufacturing auxiliary devices, processing data acquisition/processing, etc., can solve problems such as finger discomfort and reduced work efficiency, and achieve improved grip comfort and high elastic modulus Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A design and preparation method for a non-uniform rigidity grip handle (rotary handle), comprising the following steps:

[0059] Step 1, determine the shape and size of the grip handle (handle), including diameter D, shape, and thickness h;

[0060] Step 2, constructing the shell structure for gripping the handle (handle);

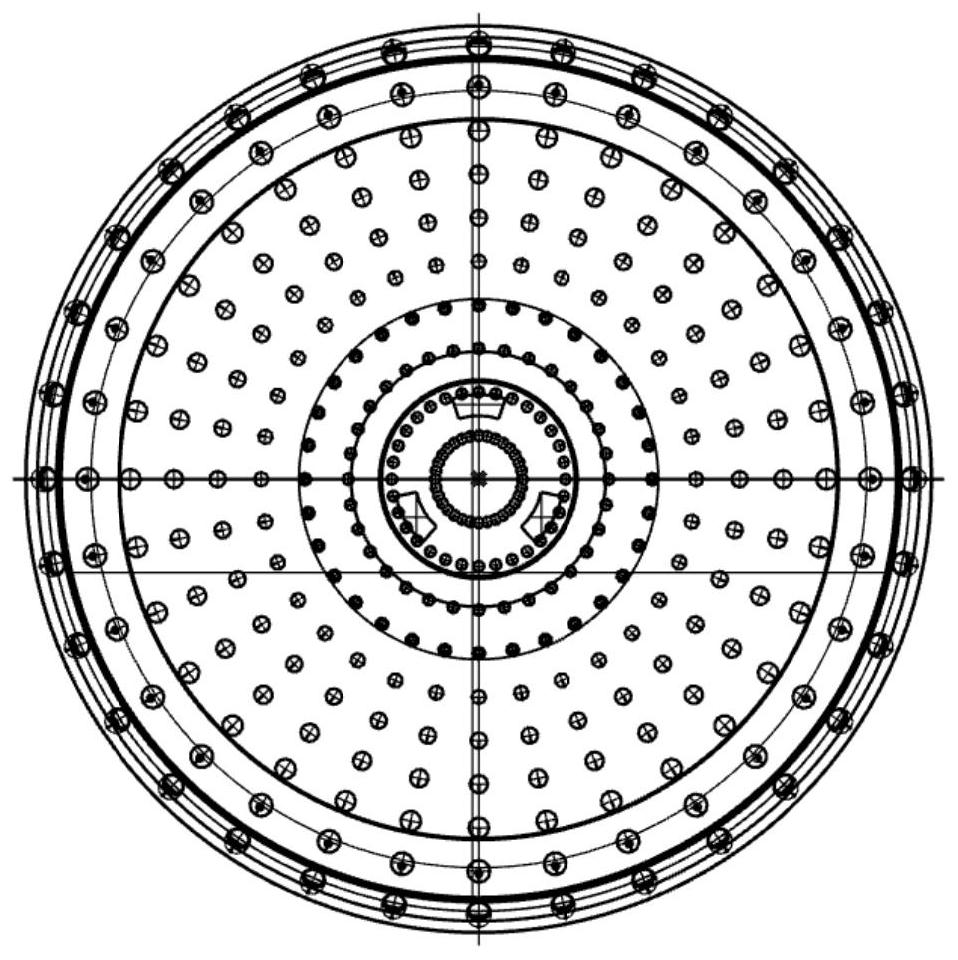

[0061] Step 3, constructing the foam structure of the gripping handle (rotary handle) in contact with the hand;

[0062]Step 4, select materials, and prepare non-uniform rigidity grip handles (rotary handles) through materials and 3D printing equipment.

[0063] Further, step 1 specifically includes:

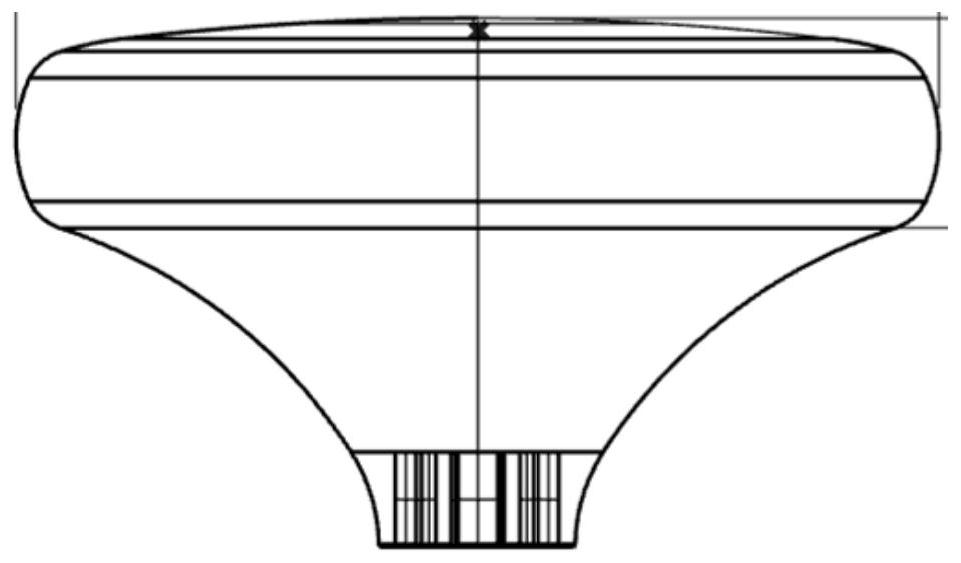

[0064] According to the size of the human hand is about 62-82mm, the diameter D of the handle (handle) is determined to be 75mm, the shape is round, and the thickness h is 17mm. figure 2 ;

[0065] In the Solidworks modeling software, carry out the modeling of the grip handle (handle), set the diameter D, thickness h, and attach figure 1 .

[0...

Embodiment 2

[0085] A method for designing and manufacturing a handle with non-uniform stiffness, comprising the following steps:

[0086] Step 1. Determine the shape and size of the handle, including outer diameter D, inner diameter d, shape, and thickness h;

[0087] Step 2, build the shell structure to hold the handle;

[0088] Step 3, constructing the unit cell structure of the part of the handle that is in contact with the hand;

[0089] Step 4, select materials, and prepare grip handles with non-uniform stiffness through 3D printing equipment.

[0090] Further, step 1 specifically includes:

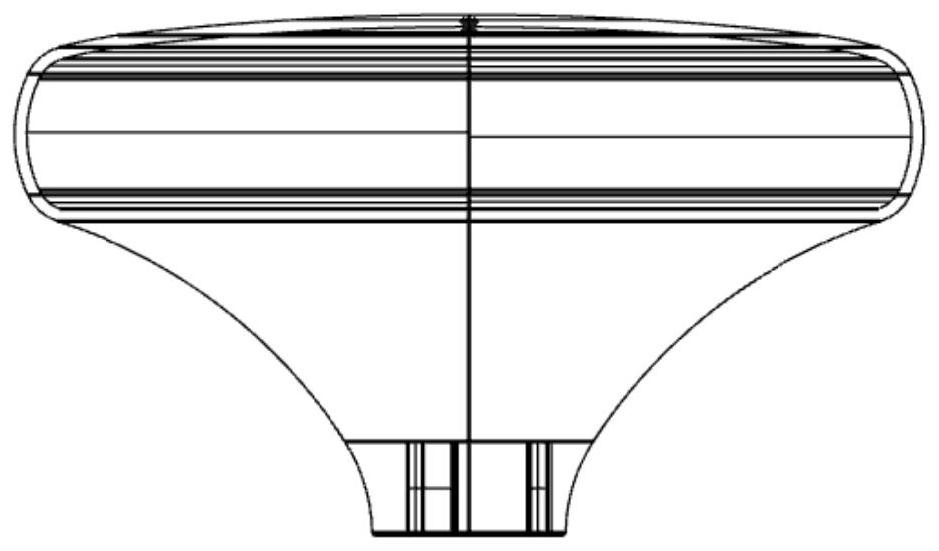

[0091] According to the size of the human hand is about 62-82mm, it is determined that the outer diameter D of the handle is about 35-40mm, the inner diameter d is 10-20mm, the shape is round, and the thickness h is about 10-15mm. figure 2 ;

[0092] Model the handle in Solidworks or RhinocerosCAD modeling software, set the outer diameter D, inner diameter d, shape, thickness h, and attach ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com