Main transmission device for strip wrapping machine

A technology of main drive and belting machine, applied in the direction of mechanical drive clutch, mechanical equipment, brake type, etc., can solve the problems of complex overall structure of belting machine, difficult manufacturing, processing and maintenance, etc., to ensure installation stability, guarantee Production processing and maintenance efficiency, the effect of ensuring work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

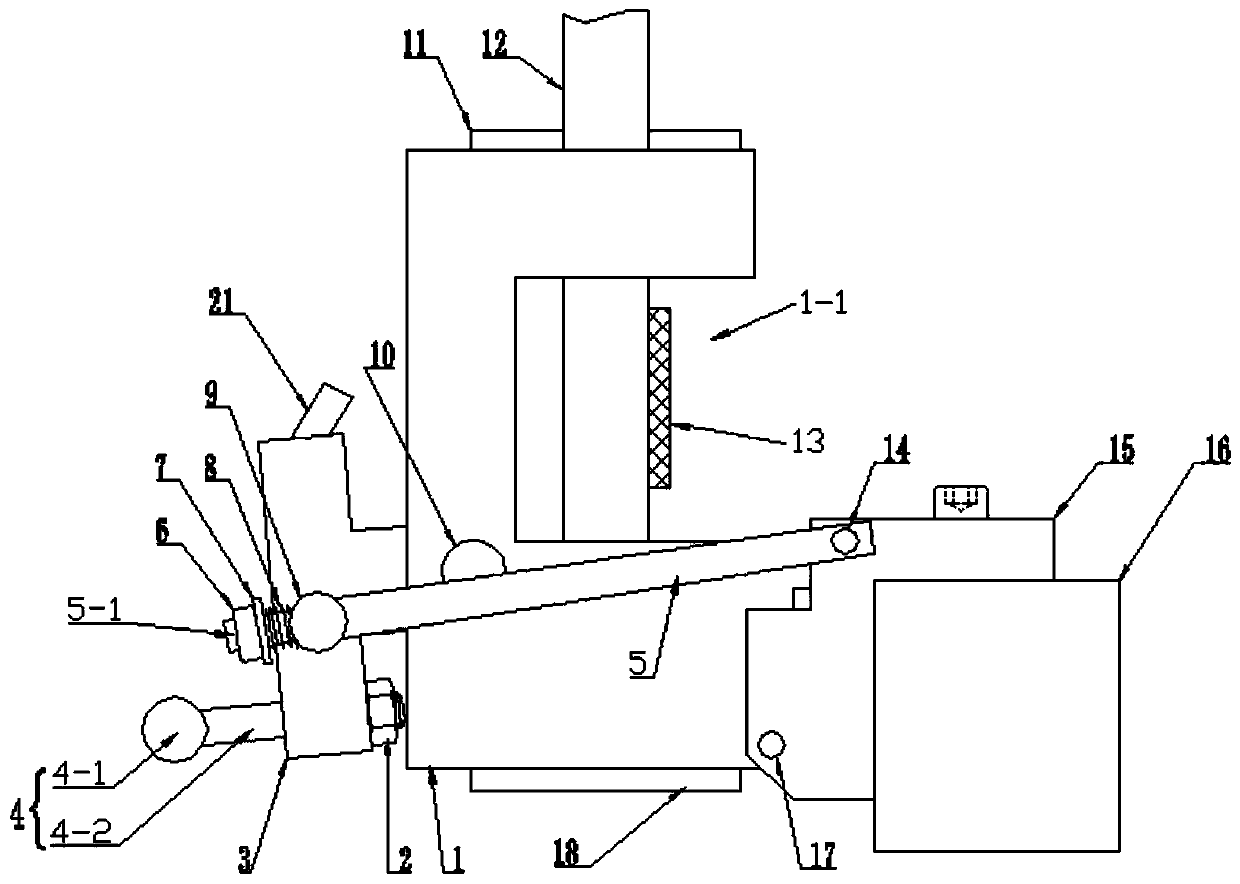

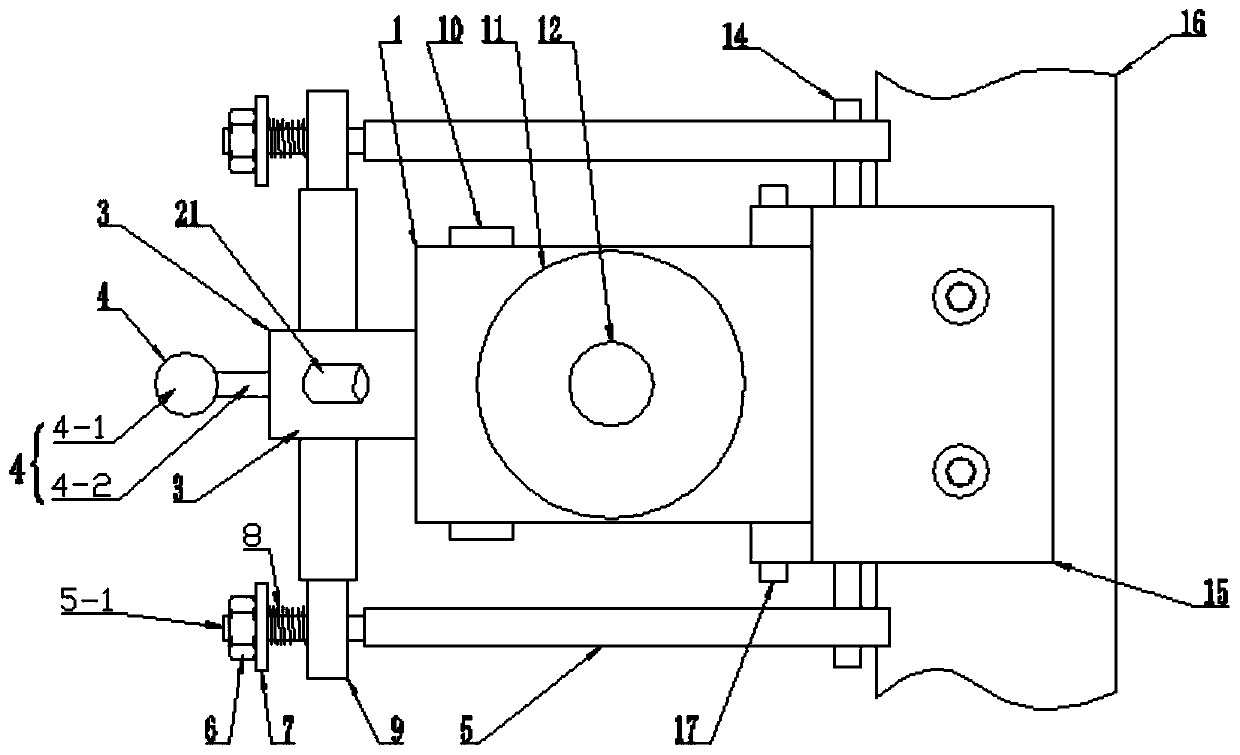

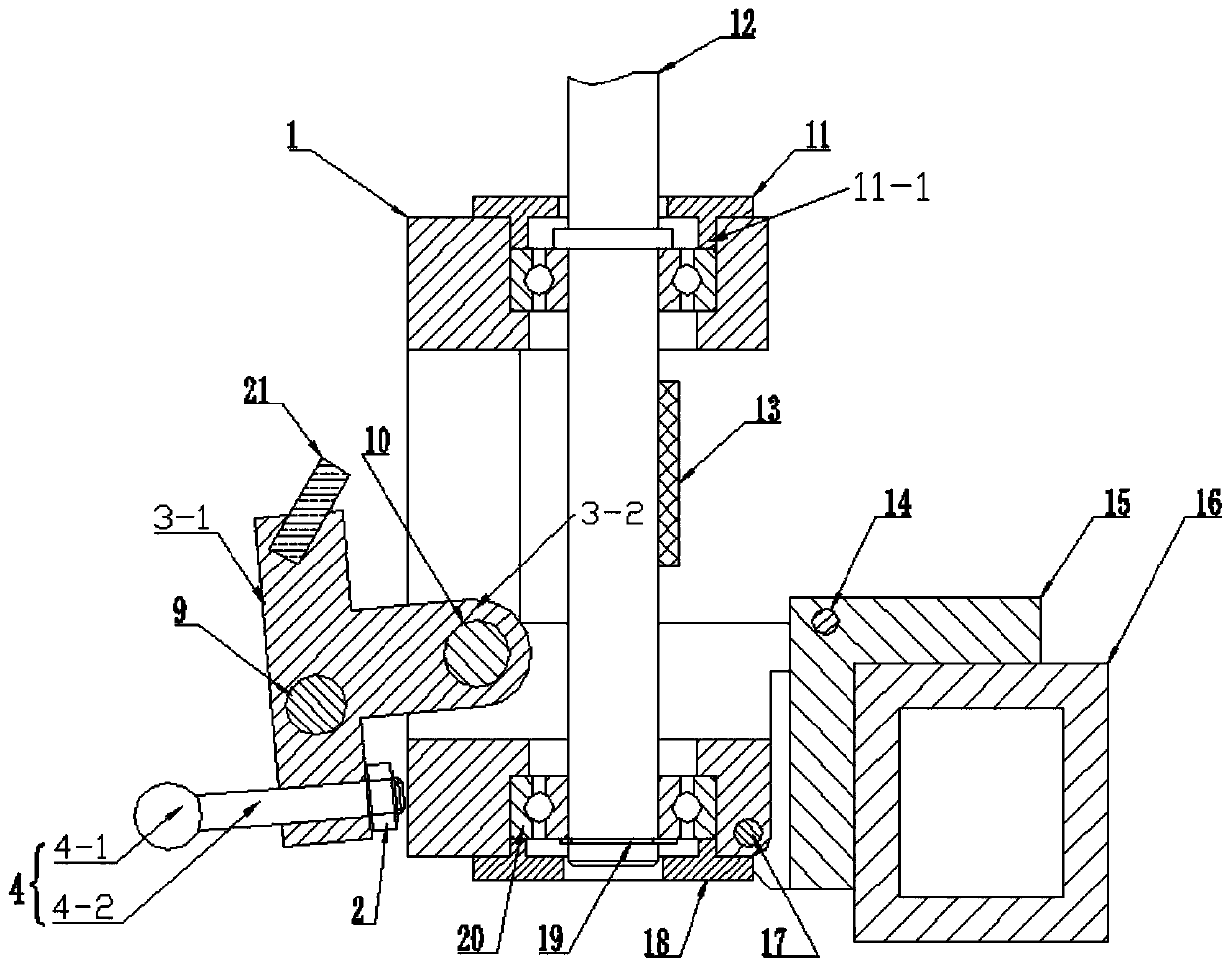

[0035] Such as Figure 1-8 As shown, a main transmission device suitable for a taping machine includes a crossbeam 16 and several transmission units, and several transmission units are detachably mounted on the crossbeam 16 at intervals, and the transmission unit includes a base 1, a main shaft 12 and a link mechanism, the main shaft 12 is vertically rotatably installed on the base 1, the lower side of the right end of the base 1 is rotatably installed on the lower end of the beam 16, and the right end of the link mechanism is rotatably connected with the upper end of the beam 16. The left end of the connecting rod mechanism is rotationally connected with the left end of the base 1, and the main shafts 12 of several transmission units are all connected to the transmission belt 13. Fitting transmission or disengagement, the main shaft 12 is provided with a line passing hole through the axis.

[0036] Preferably, the transmission unit further includes a first bracket 15, the fi...

Embodiment 2

[0047] Such as Figure 9As shown, a copper foil wrapping device is used to produce copper foil signal lines. The main transmission device described in Embodiment 1 is applied to the copper foil wrapping device. The upper end of the main shaft 12 is processed into a large bottom and a small top The tapered structure, the upper end of the main shaft 12 is sequentially sleeved with a tape storage cylinder 22, a tape assembly 23, a conical spring 25 and a fixed ring 24, and the tape storage cylinder 22 is provided with a tapered installation penetrating through the shaft center. hole, the fixed ring 24 is fixed on the upper end of the main shaft 12, the conical spring 25 is sleeved on the main shaft 12 between the fixed ring 24 and the strap assembly 23, and the fixed ring 24 passes through the conical spring 25 abutting and pressing the strap assembly 23 and the storage drum 22 .

[0048] As a preference, the strap assembly 23 includes a first bracket 23-2, a second bracket 23-4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com