Engine room escape routes for chemicals/oil tankers

An escape passage and chemical technology, applied in the field of cabin escape passages, can solve the problem of large space occupied by inclined ladders, and achieve the effects of improving grip comfort and firmness, good wear resistance, and improving grip comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

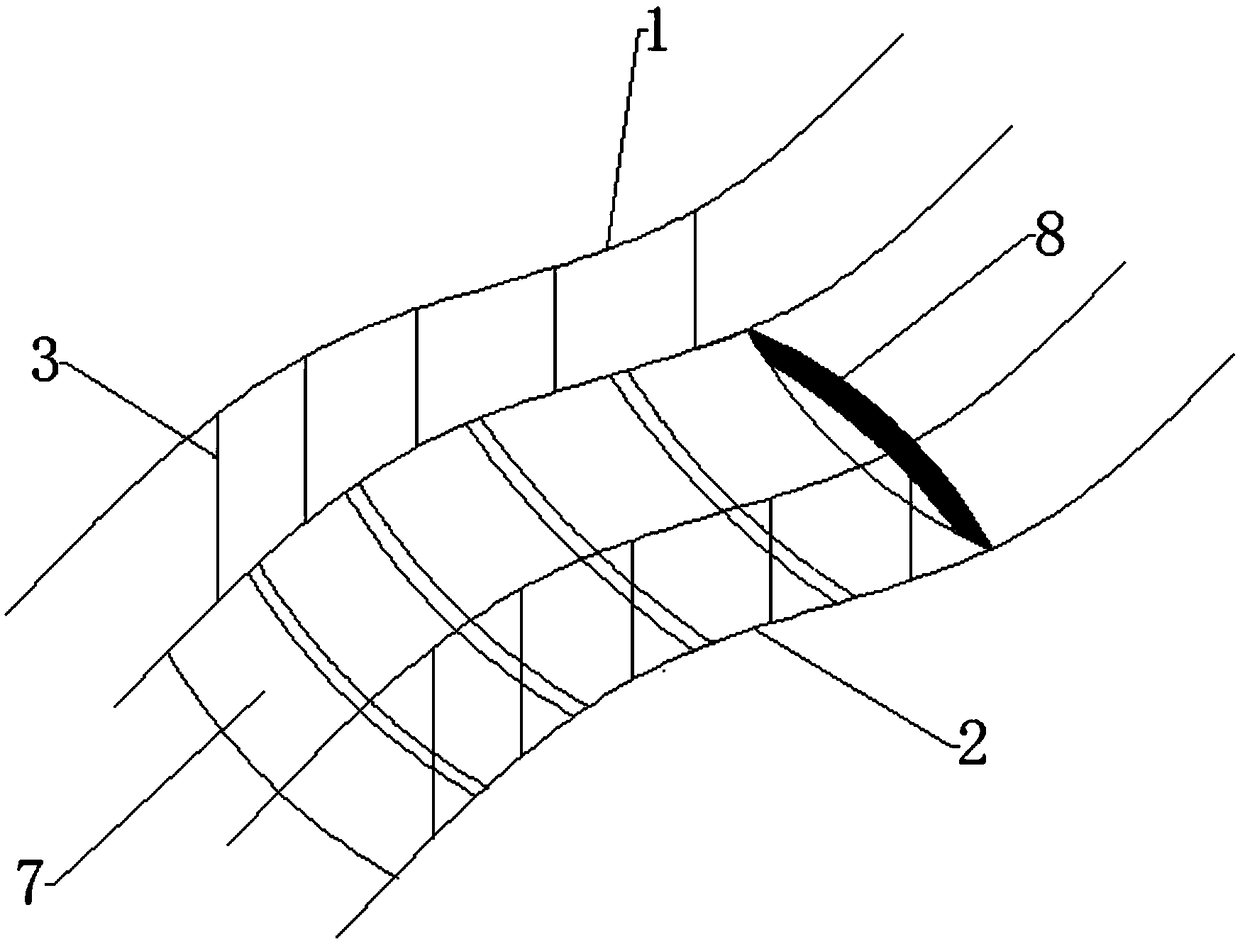

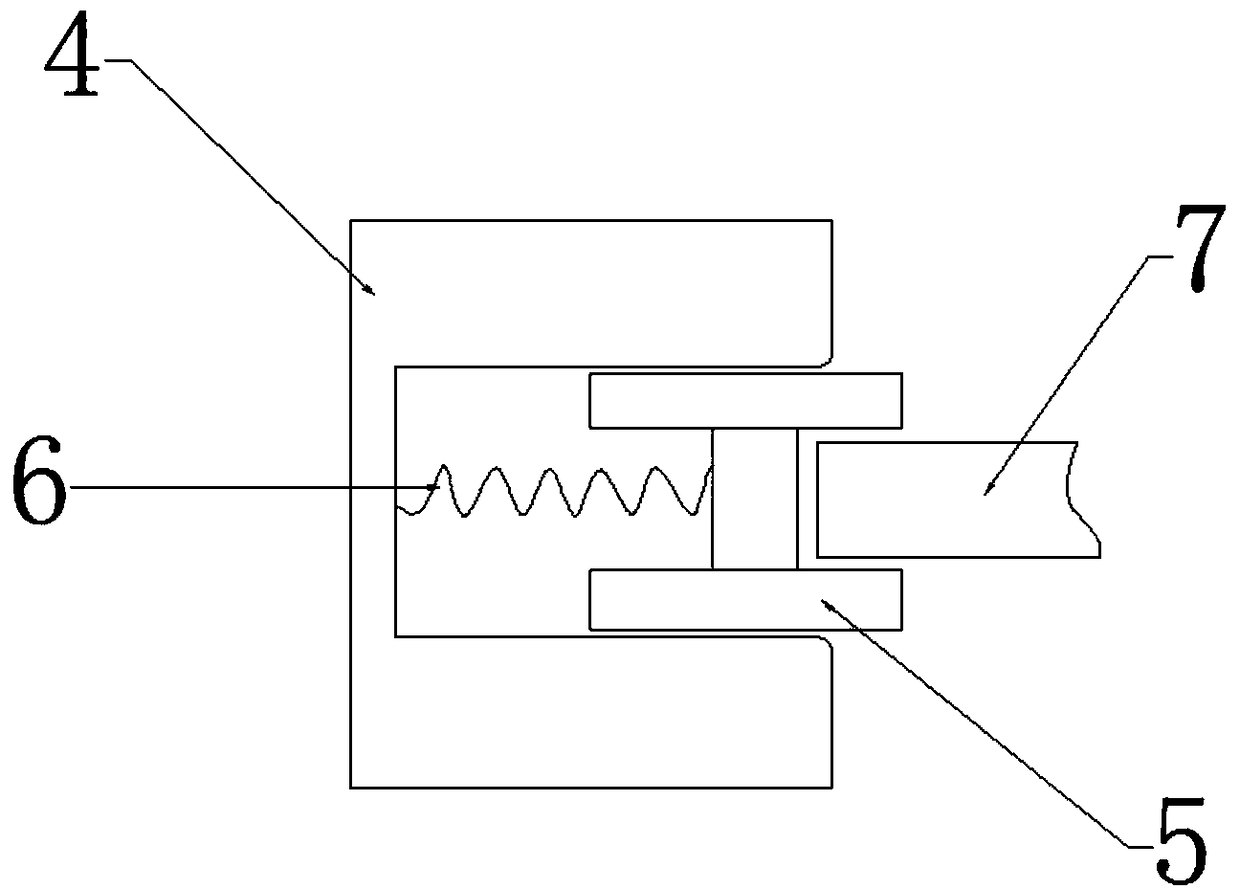

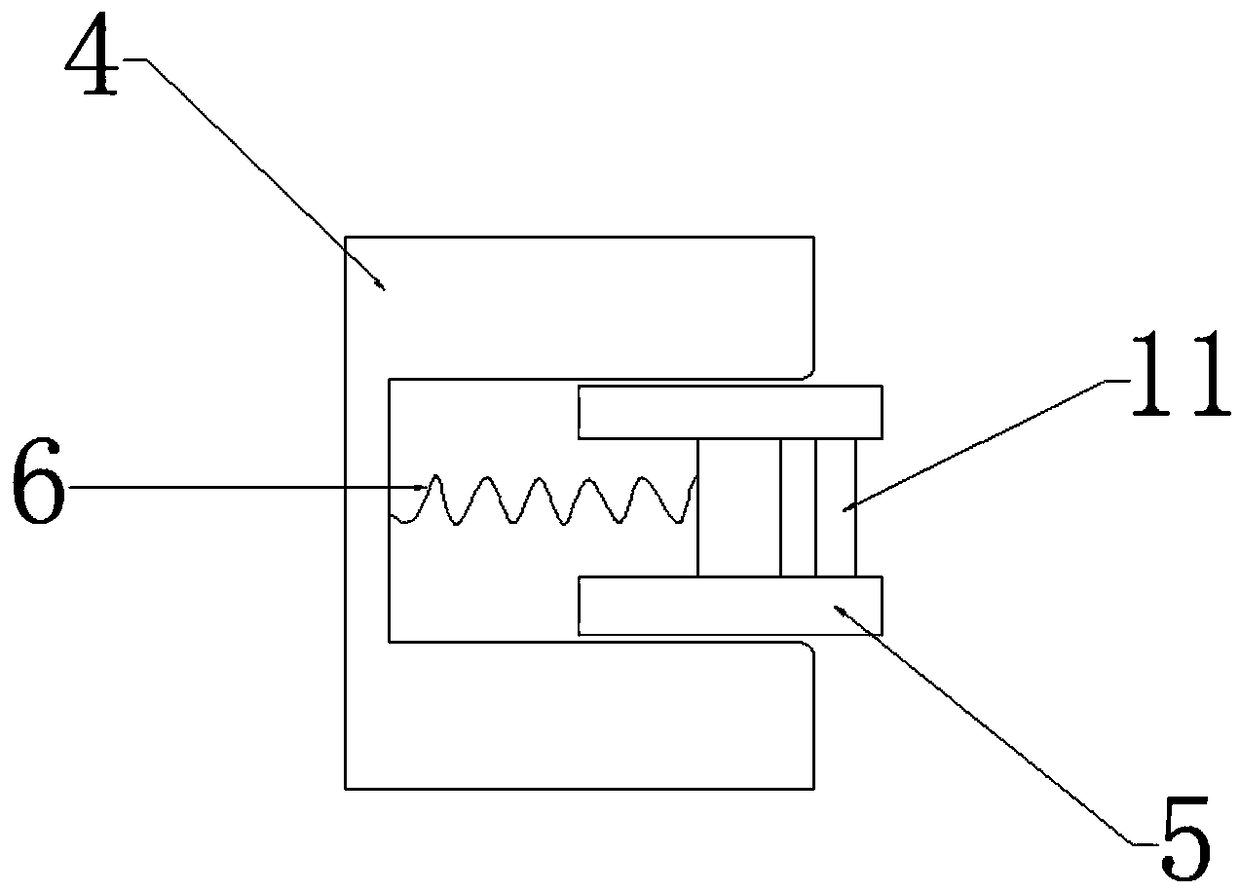

[0026] Such as figure 1 , Figure 2a and Figure 2b As shown, the engine room escape channel of the chemical / oil tanker includes a spiral stair frame, a pedal bracket 5 arranged on the stair frame and a pedal 7 horizontally installed on the pedal bracket 5, and it is characterized in that the stair frame includes parallel The left half of the ladder frame and the right half of the ladder frame are set, and the left half of the ladder frame and the right half of the ladder frame all include an upper spiral pipe 1 and a lower spiral pipe 2 arranged in parallel, and the upper spiral pipe 1 A number of connecting rods 3 are vertically arranged between the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com