Pipe limiting devices and pipe lifting equipment

A technology for limiting devices and pipe fittings, applied in the directions of transportation, packaging, conveyors, etc., can solve the problems of pipe fittings slipping, poor pipe compatibility, and insufficient restrictions, avoiding shaking, improving shape fit, and improving compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following detailed description is merely the limitation of the invention, which will be a modification of the present embodiment without creative contributions to this embodiment after reading the present invention after reading the present invention. It is required to be protected by patent law.

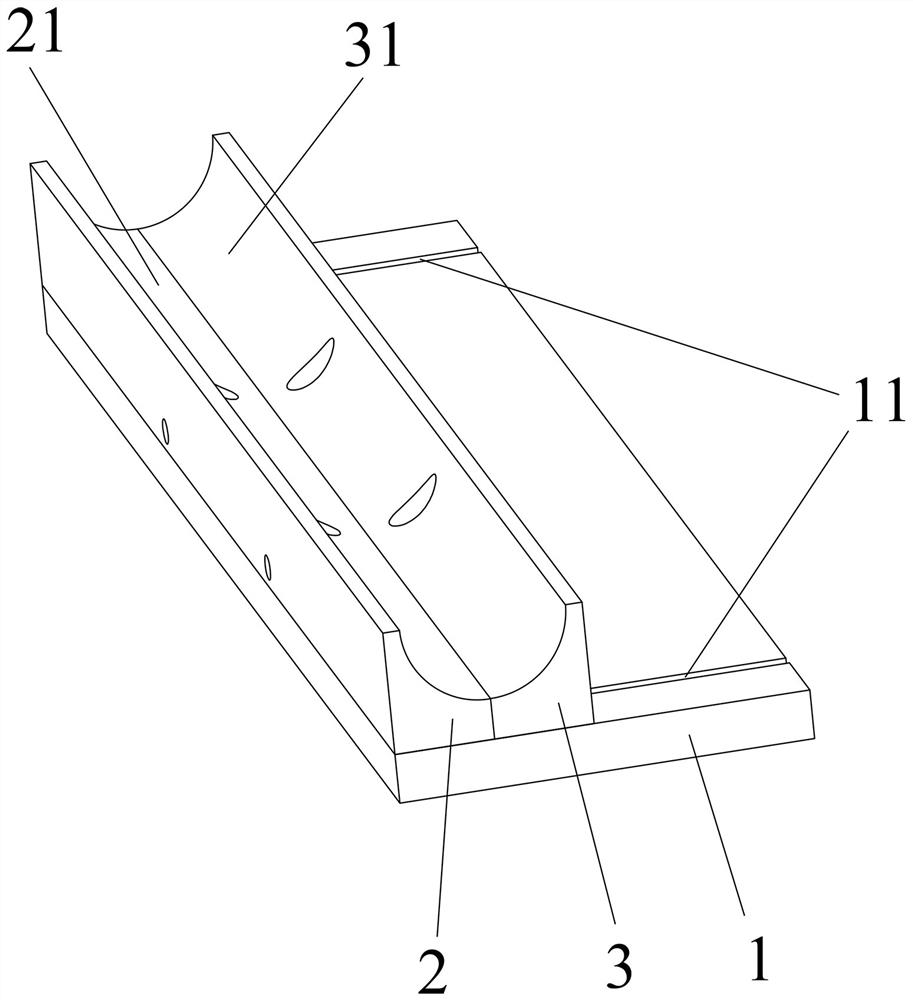

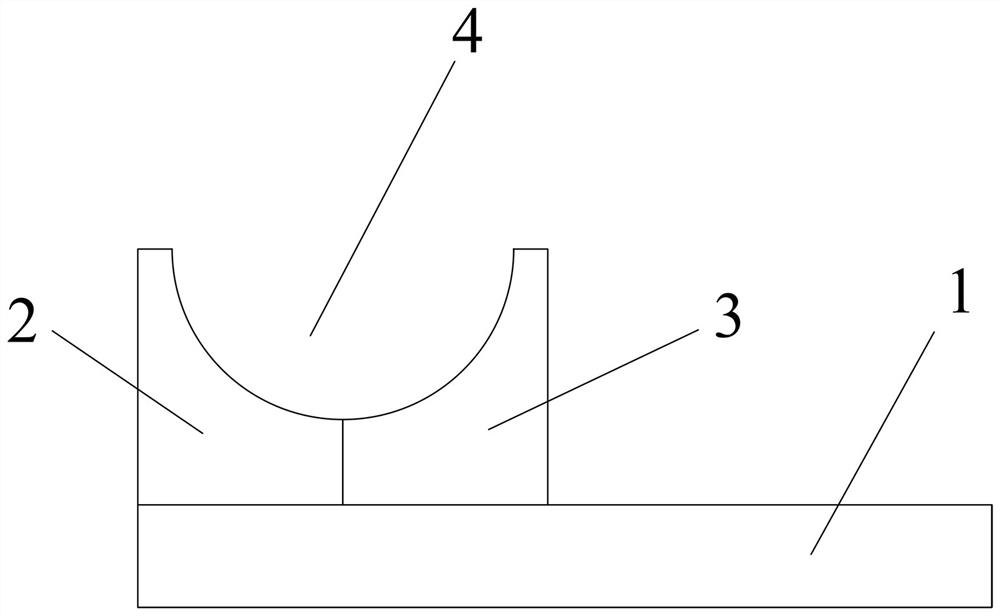

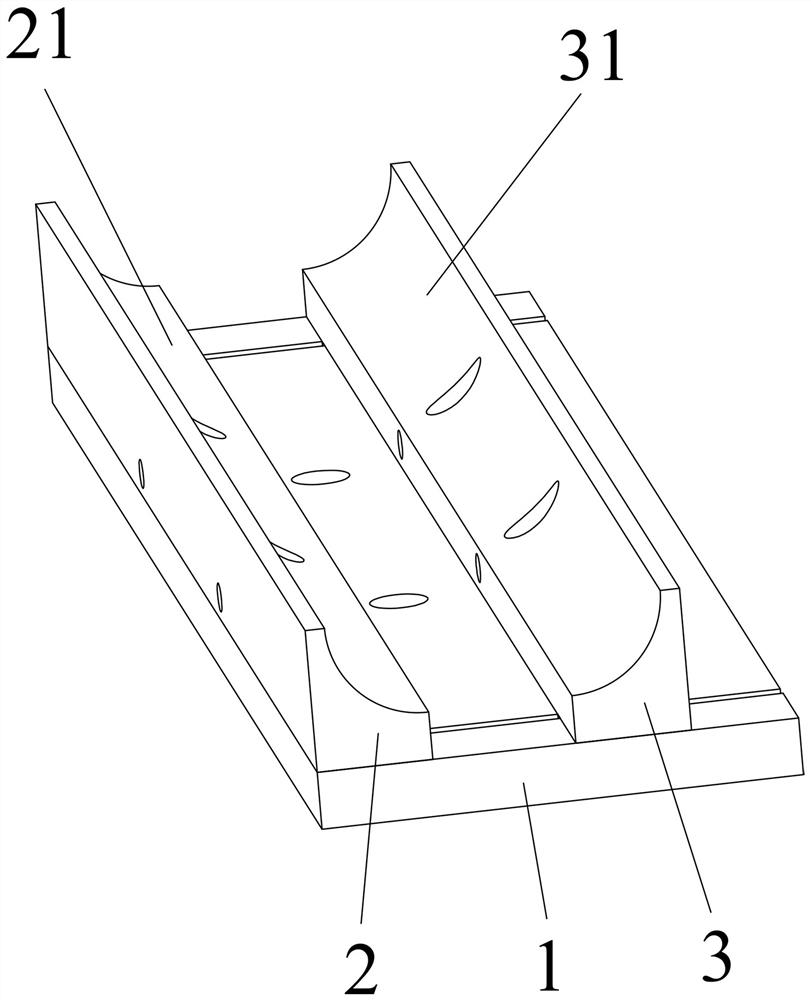

[0035] figure 1 A tube restricted device of the present invention is shown, including a base mounting plate 1, a front carrier holder 2 and a rear carrier 3, and a rear carrier 3, which are arranged on the base mounting plate 1, and the front carrier holder 2 has a support. The front support surface 21 of the pipe has a rear support surface 31 for supporting the tubing, and a housing groove 4 for limiting the tubing is formed between the front support surface 21 and the rear support surface 31. The tubular limit device A is mainly used to limit and carry the tube member in the lifting device, and the tube member is lifted, so the tube restricted device A needs to be fixed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com