Brush carrier assembly

A technology of assembly and brush, applied in the direction of casing/housing/support, electrical components, electromechanical devices, etc., can solve problems such as brush bias and failure to obtain brush wear status in real time, and achieve the goal of improving product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the accompanying drawings.

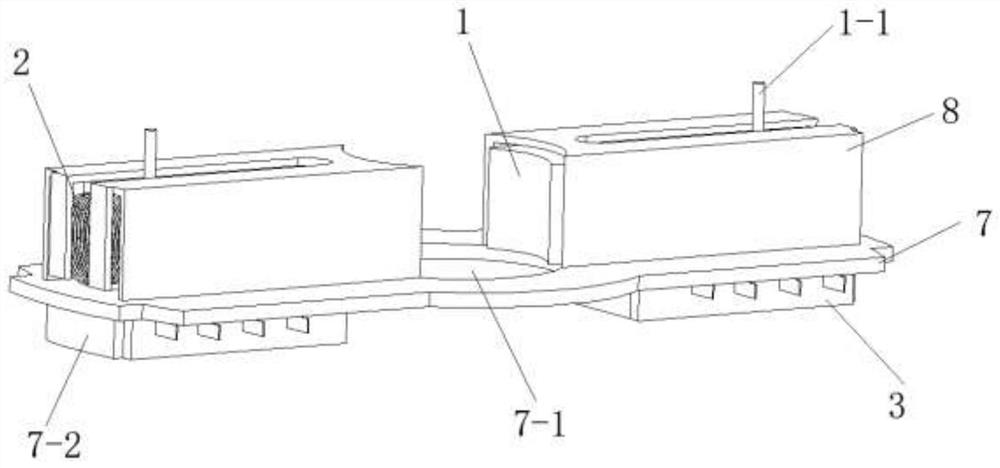

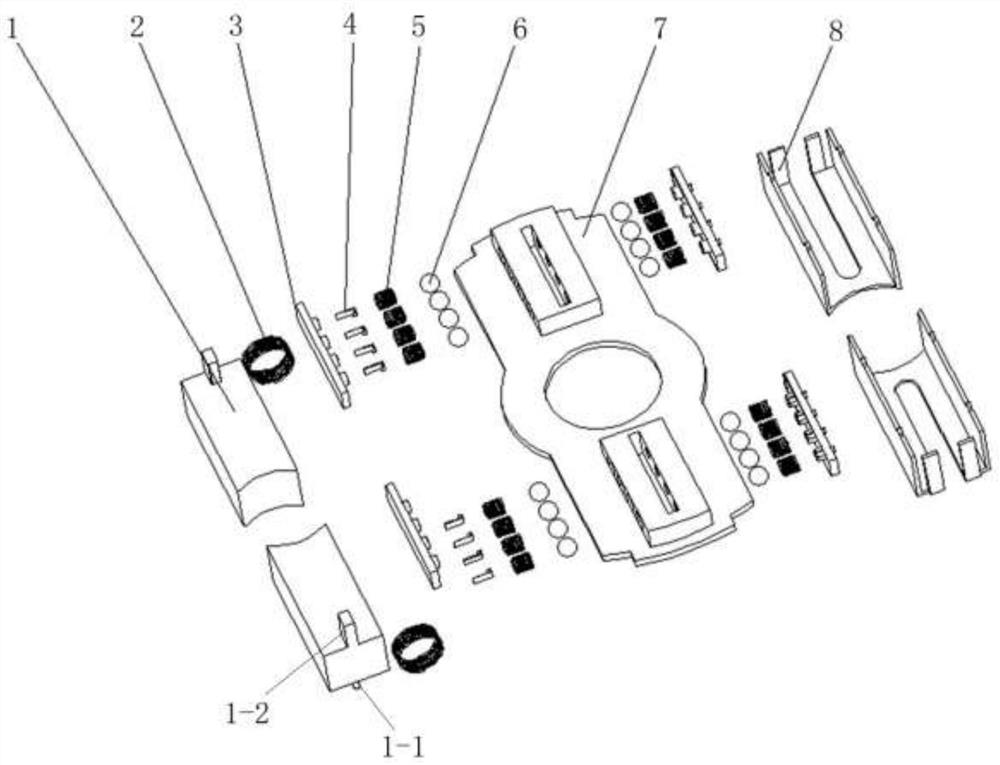

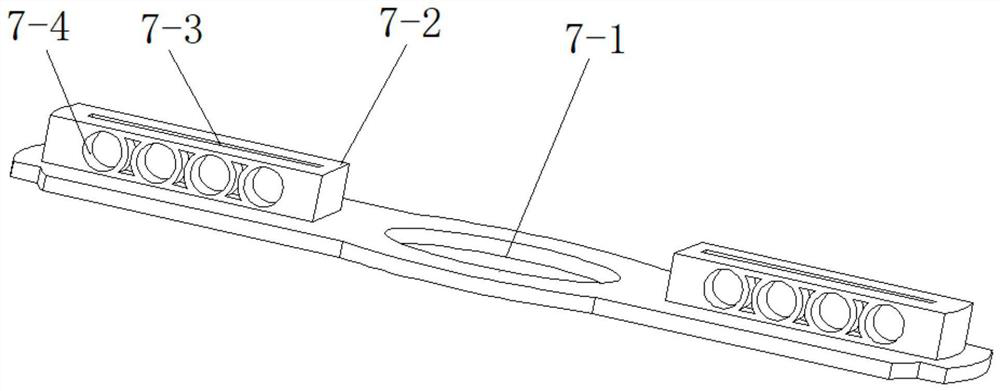

[0021] like Figures 1 to 3 As shown, a brush holder assembly of the present invention includes a brush plate 7, and the center of the brush plate 7 is provided with an assembly hole 7-1 for installing the steering gear. The steering gear is cylindrical and installed in the assembly hole 7-1 And can rotate freely.

[0022] Two brush boxes 8 are arranged symmetrically on both sides of the assembly hole 7 - 1 , and the brush boxes 8 are pressed and fixed on the surface of the brush plate 7 . Inside each brush box 8, a brush 1 that can move back and forth is arranged along the radial direction of the assembly hole 7-1. The top surface of the brush 1 has a brush braid 1-1 for connecting the power supply. The brush spring 2, the end of the brush spring 2 leans against the inner wall of the end of the brush box 8, and the front end leans against the brush 1, and the brush ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com