Rotary raw coal iron removal device for coal mining

A rotary, raw coal technology, used in magnetic separation, solid separation, chemical instruments and methods, etc., can solve problems such as equipment damage and achieve the effect of preventing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

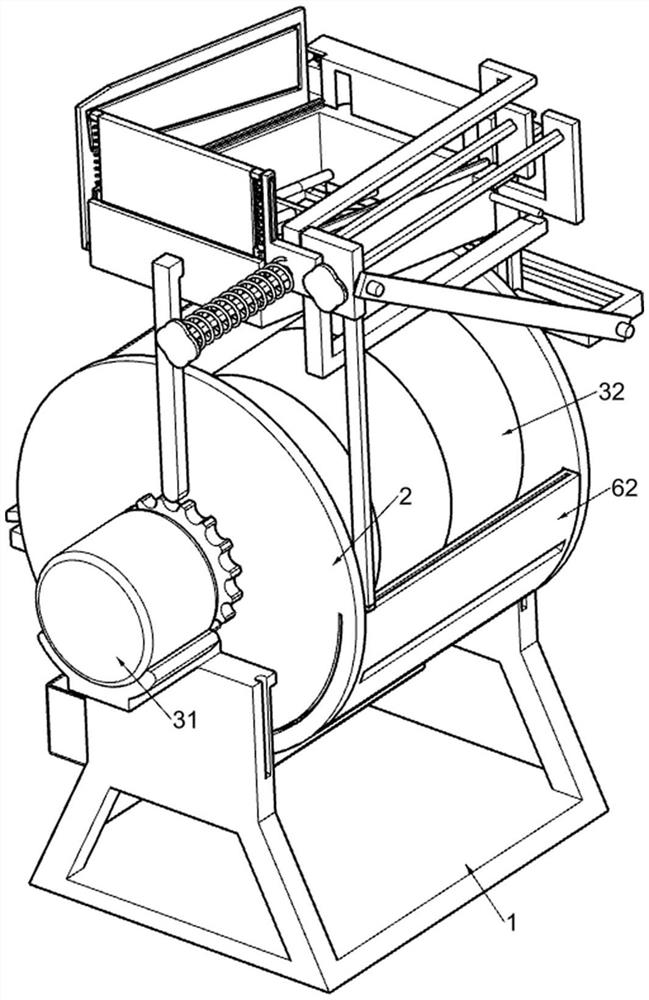

[0028] A kind of rotary raw coal iron removal device for coal mining, such as Figure 1-7 As shown, it includes a support chassis 1, a slotted support disc 2, a separation plate 201, a classification frame 202, a screening assembly 3, an anti-stacking assembly 4 and a reset assembly 5, and two slotted supports are fixedly installed on the support chassis 1. Disc 2, two slotted supporting discs 2 are jointly welded with a separation plate 201, and the support chassis 1 is provided with two sorting frames 202, the sorting frame 202 is used to place coal and metal objects, and is used to screen coal The assembly 3 is arranged on the support base frame 1 , the anti-stack assembly 4 for preventing coal accumulation is arranged on the screening assembly 3 , and the reset assembly 5 is also arranged on the screening assembly 3 .

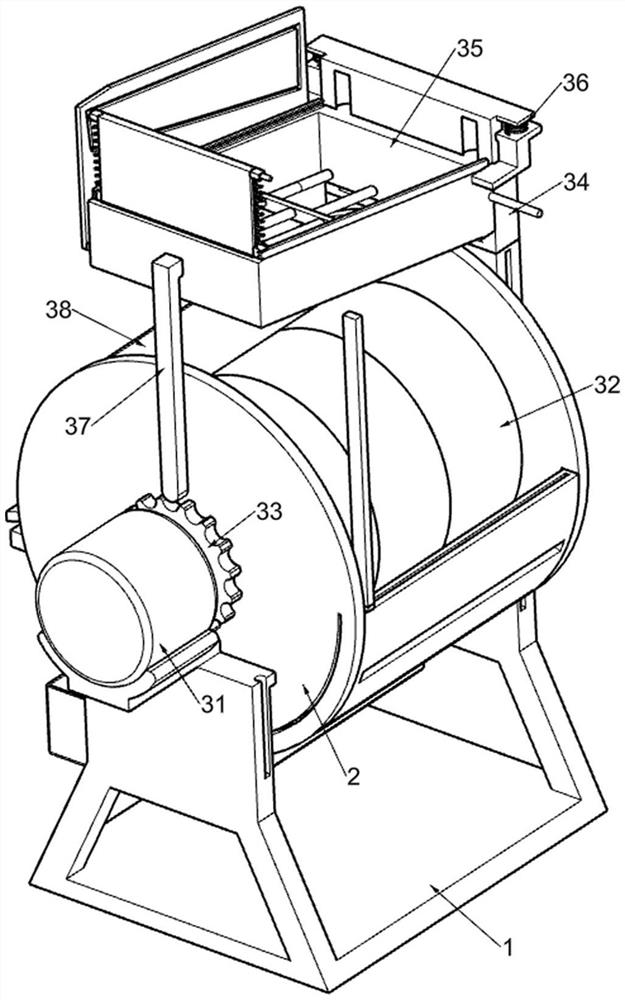

[0029] The screening assembly 3 includes a motor 31, a magnetic roller 32, a vibrating plate 33, a support plate 34, a multi-stage inclined screen frame 35...

Embodiment 2

[0037] On the basis of Example 1, such as Figure 8-9 As shown, it also includes a toggle assembly 6, the two slotted support discs 2 are jointly provided with a toggle assembly 6, the toggle assembly 6 is used to push aside the metal objects contained in the coal, and the toggle assembly 6 includes a second Two transmission rods 61, slotted plates 62 and arc toggle plates 63, the second transmission rods 61 are welded on the reset frame 56, two slotted support discs 2 are jointly provided with slotted plates 62, and the slotted plates 62 and Classification frames 202 are in contact with each other, and the slotted plate 62 is slidably connected with an arc toggle plate 63. The arc toggle plate 63 is used to toggle the coal on the slot plate 62, and the arc toggle plate 63 is connected to the first Two transmission rods 61 are fixedly connected.

[0038] When the coal slides down from the magnetic roller 32, the coal will slide down into the internal sorting frame 202 through...

Embodiment 3

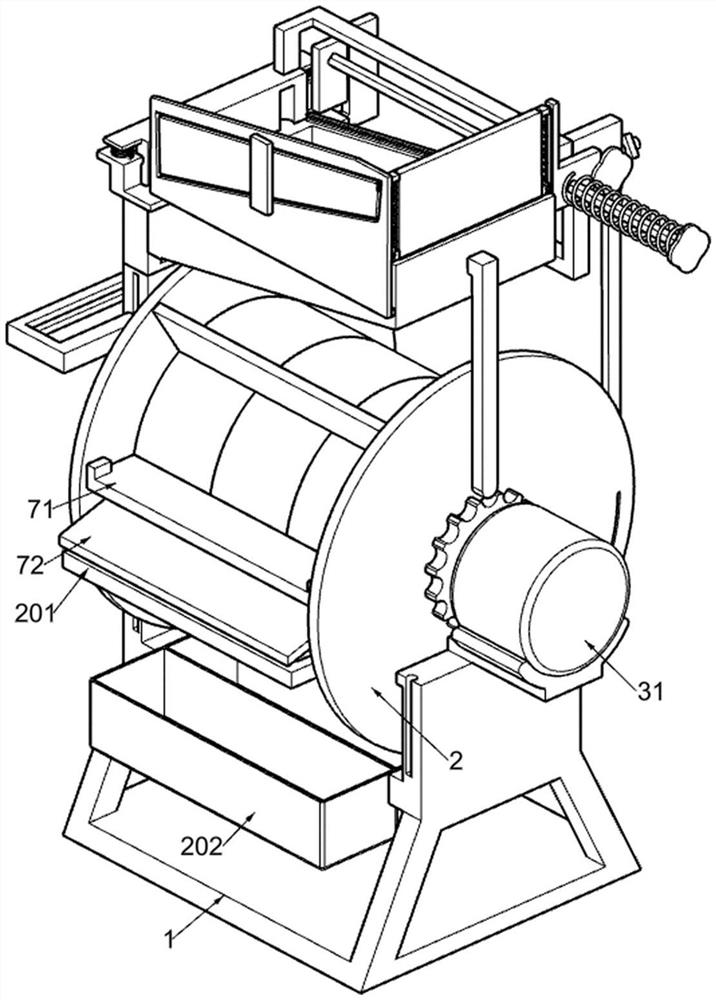

[0040] On the basis of Example 2, such as Figure 10 As shown, it also includes an iron filings removal assembly 7, and the iron filings removal assembly 7 is jointly arranged on the two slotted support discs 2, and the iron filings removal assembly 7 is used to remove iron filings on the magnetic roller 32, and the iron filings removal assembly 7 Comprising a scraper plate 71 and a second guide plate 72, the two grooved support discs 2 are welded together with a scraper plate 71, the scraper plate 71 is in contact with the magnetic roller 32, and the scraper plate 71 is used to move the magnetic roller 32 The iron filings adsorbed on the top are scraped off, and the second guide plate 72 is also welded on the two grooved support discs 2, and the second guide plate 72 is also in contact with the magnetic roller 32, and the second guide plate 72 is used for scraping off Iron filings are guided.

[0041] The scraping plate 71 can scrape off the iron filings adsorbed on the magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com