Riveting tool and using method thereof

A technology for riveting tooling and tooling plates, which is applied to auxiliary devices, feeding devices, positioning devices, etc., can solve the problems of long time and complicated switching process of riveting tooling, so as to reduce usage, reduce positioning switching time, and reduce on-site venues. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

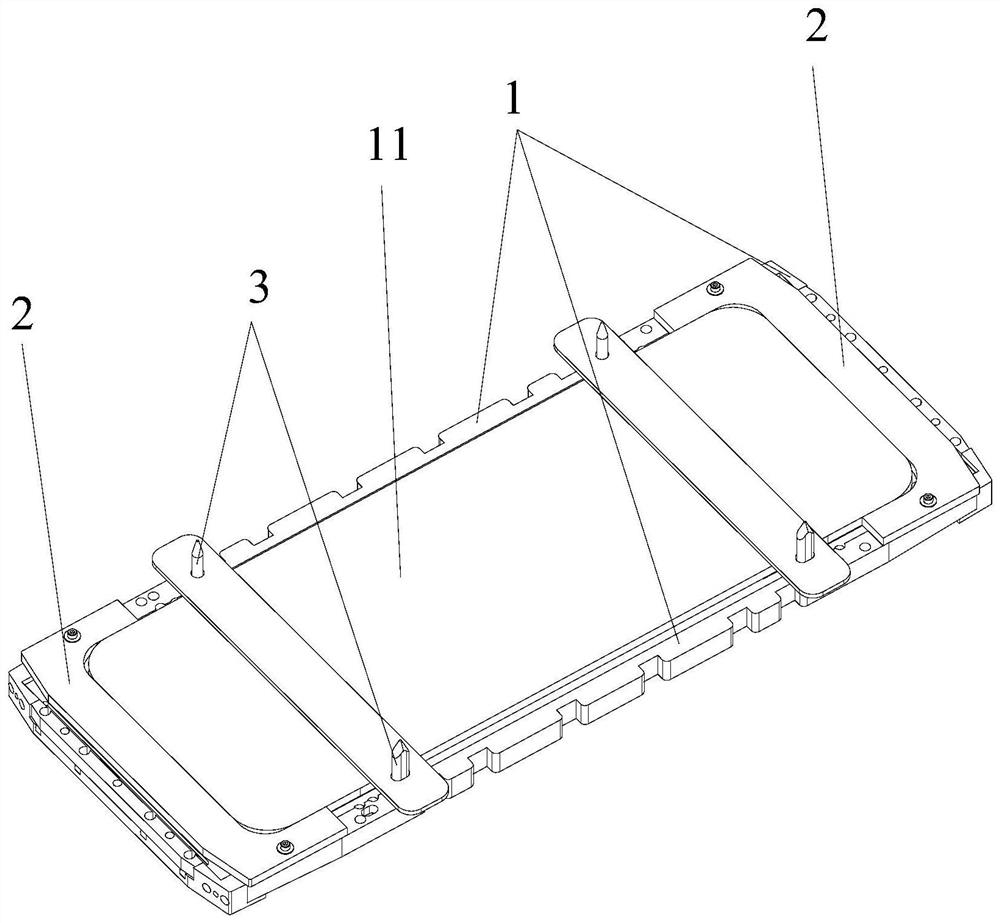

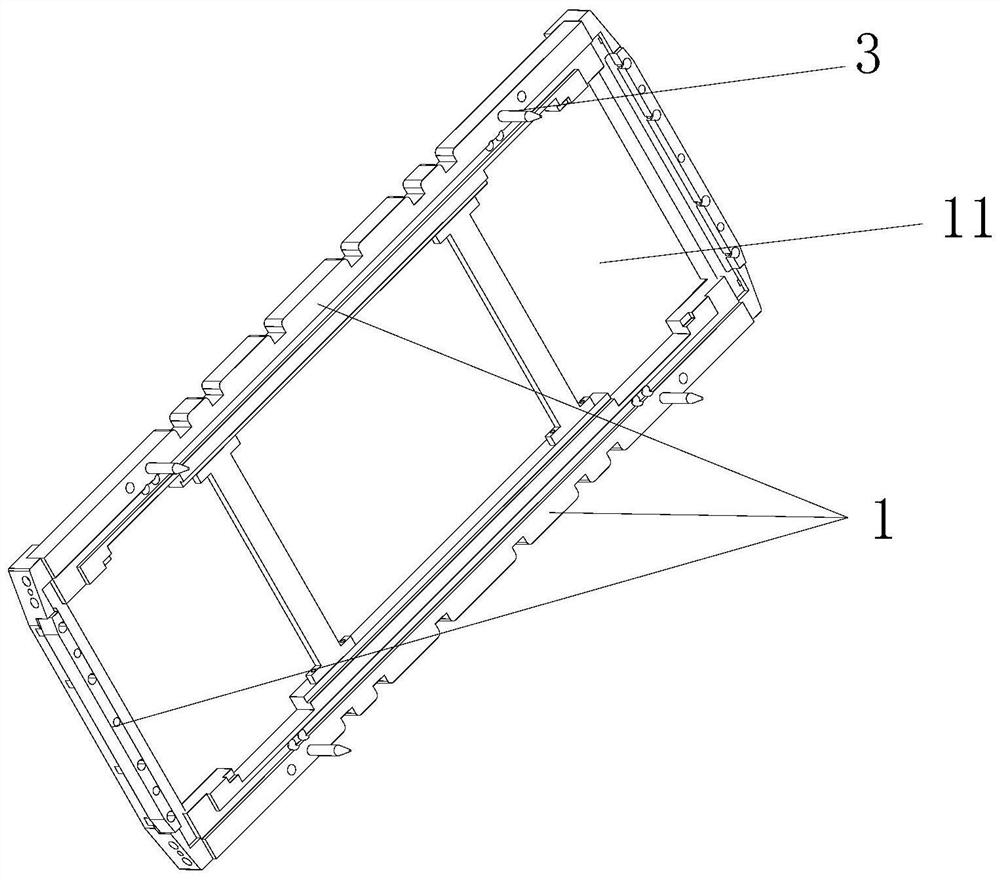

[0028] Such as figure 1 and figure 2 The shown riveting tooling includes: a plurality of tooling plates 1, all the tooling plates 1 together form an accommodation groove 11, and parts are placed in the accommodation groove 11; a limit mechanism 2, the limit mechanism 2 can slide The opening of the accommodating groove 11 is grounded, and the limiting mechanism 2 can abut against the peripheral side of the part.

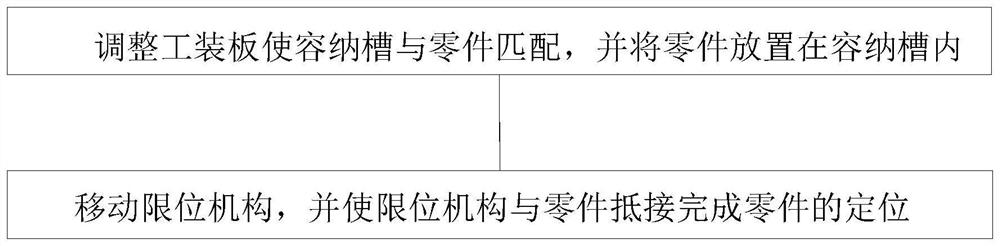

[0029] When positioning the parts, it is only necessary to place the parts in the receiving groove 11, and then move the limit mechanism 2 so that the limit mechanism 2 abuts against th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap