Rotary bottle blowing machine bottom die structure for medical infusion bottle production

A rotary blow molding machine technology, applied in the field of blow molding machines, can solve the problems of long trial period, cumbersome parts replacement, sticking together, etc., and achieve the effect of improving product qualification rate and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

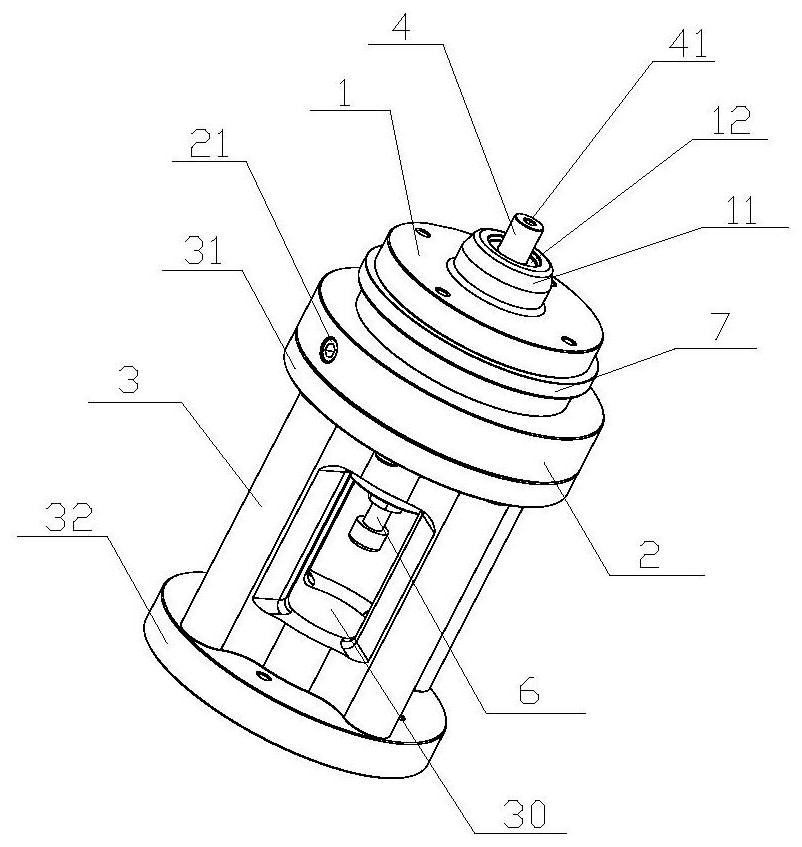

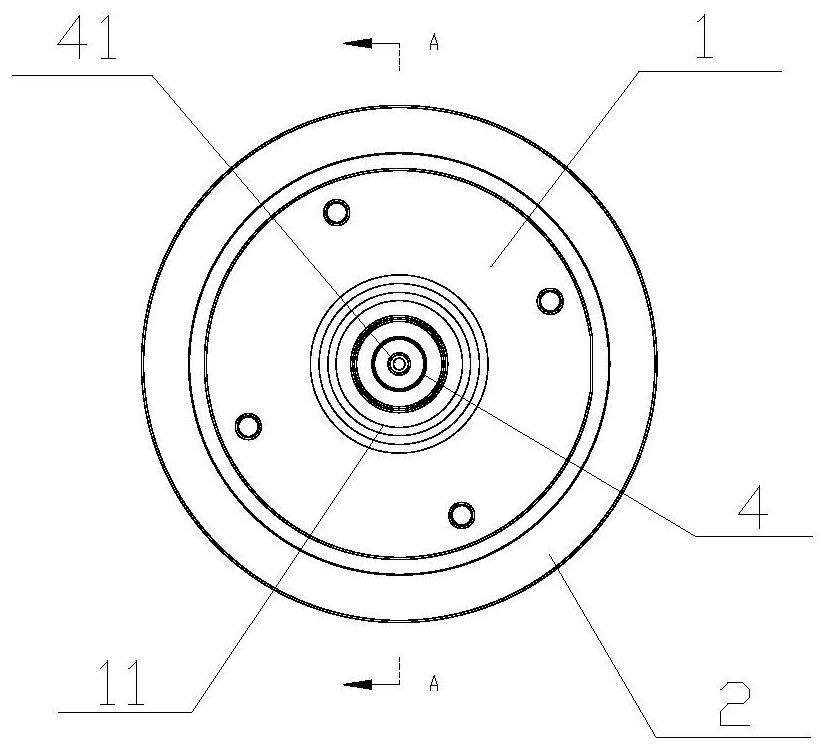

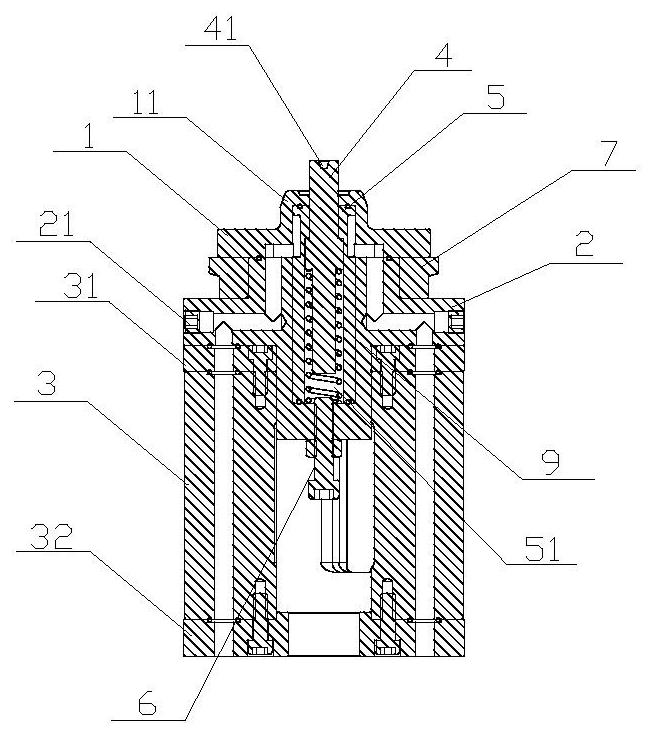

[0030] refer to Figure 1 to Figure 13 , this embodiment provides a bottom mold structure of a rotary blow molding machine for the production of medical hanging bottles, including a bottom mold 1, a water sealing plate 2, a support frame 3, a cooling core 5, a guide rod 4 and a jacking mechanism 6, The bottom mold 1 is installed on the water sealing plate 2, and the water sealing plate 2 is installed on the support frame 3. The upper end of the bottom mold 1 extends upwards out of the hanging bottle support part 11, and the upper end of the hanging bottle supporting part 11 is provided with a ring groove 12, and the hanging ring The groove 12 is connected with the guide hole, the upper and lower ends of the cooling core 5 are respectively installed inside the bottom mold 1 and the water sealing plate 2, the inside of the cooling core 5 is provided with a cavity 51 with the upper and lower ends open, and the guide rod 4 is installed in the cavity 51 and can move up and down alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com