Clamp for electroplating machining production

A fixture and electric cylinder technology, which is applied in the field of fixtures for electroplating processing, can solve the problems of reducing product electroplating efficiency, wasting labor, wasting electroplating time, etc., and achieve the effects of reducing product shedding rate, saving labor waste, and improving electroplating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

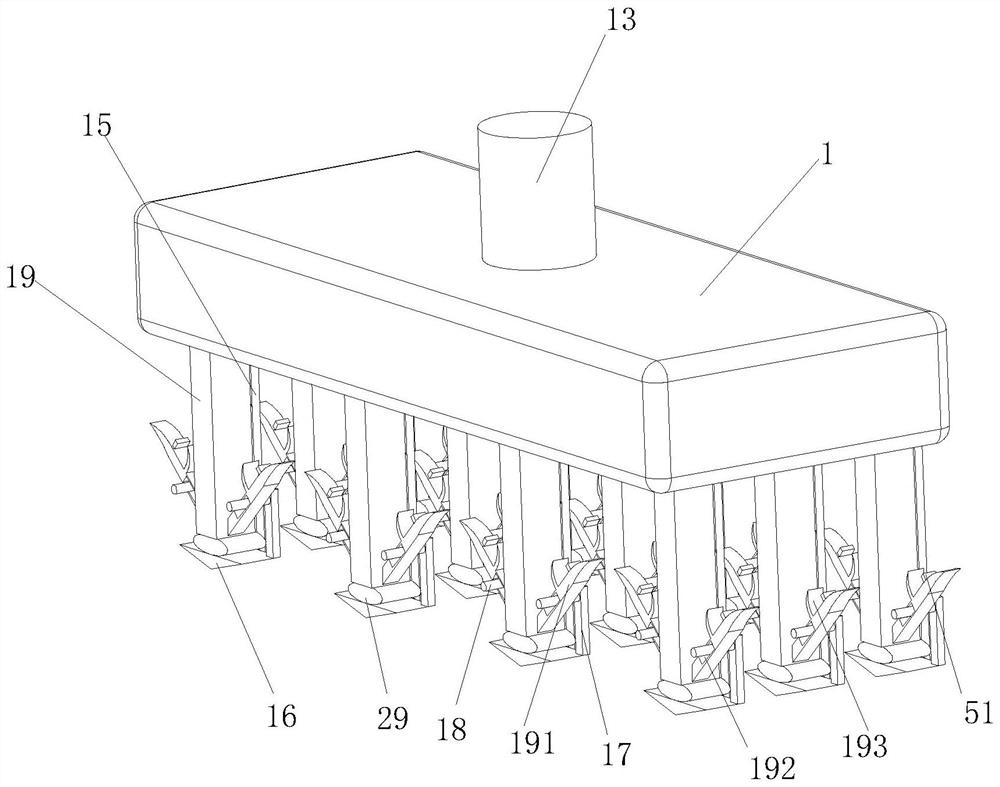

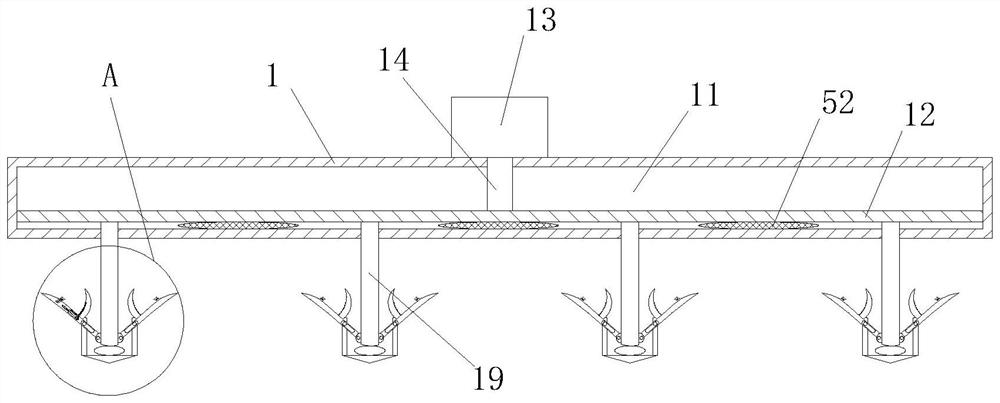

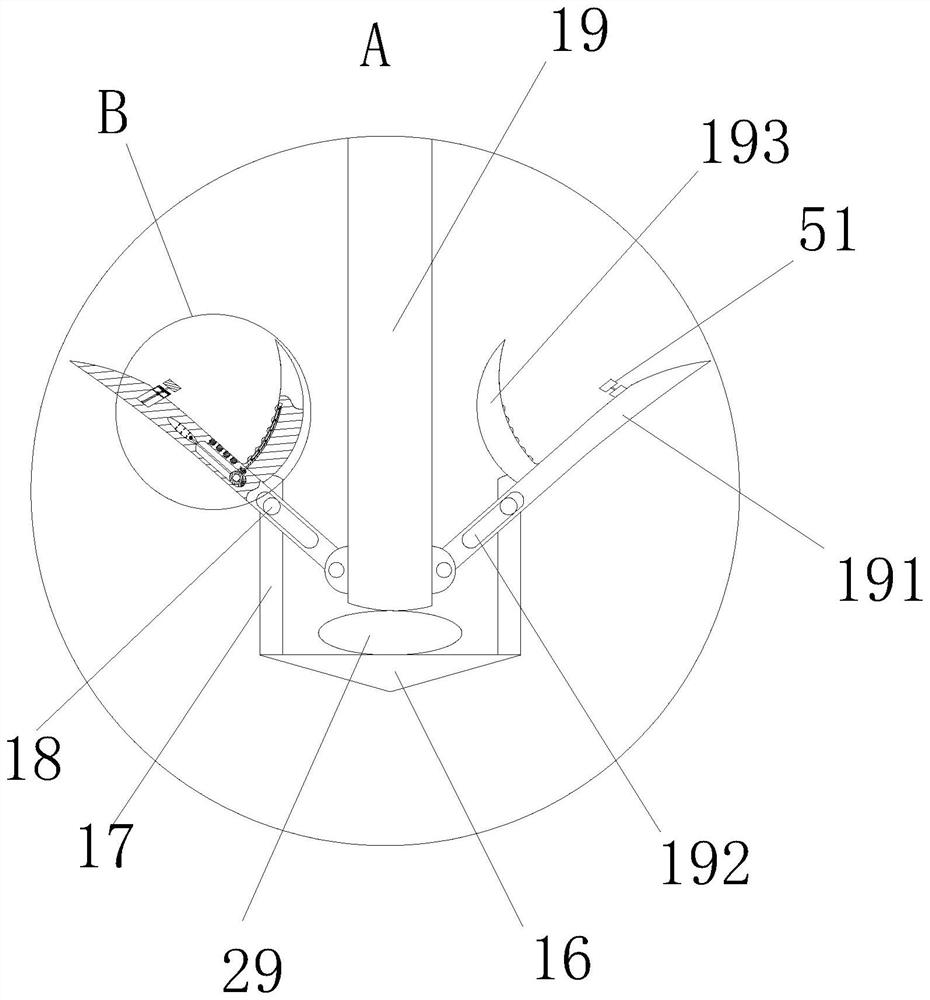

[0033] like Figure 1 to Figure 8 As shown, a jig for electroplating processing production according to the present invention includes a support plate 1; a first cavity 11 is opened in the support plate 1, and a moving plate 12 is slidably connected to the first cavity 11. ; The top of the support plate 1 is fixedly connected with an electric cylinder 13, and the electric cylinder 13 is provided with an electric rod 14, and the electric rod 14 extends into the first cavity 11 and is fixed on the top of the moving plate 12; the support plate 1. A group of fixed blocks 16 are fixedly connected to the bottom end through the fixed column 15; a pair of symmetrically distributed vertical plates 17 are fixed to the fixed blocks 16, and fixed shafts 18 are fixed to the vertical plates 17; the bottom of the moving plate 12 A moving rod 19 is fixedly connected to the position of the end relative to the fixed block 16; the moving rod 19 runs through the first cavity 11, and the two sides...

Embodiment 2

[0043] like Figure 9 As shown in Comparative Example 1, as another embodiment of the present invention, a set of anti-slip lines 47 are provided in the roller 41; during operation, the rotation of the roller 41 can not only loosen the electroplated product but also reduce friction In order to prevent sliding friction between the roller 41 and the product, the roller 41 is provided with anti-skid lines 47, which can avoid the product of sliding friction and ensure the rotation of the roller 41.

[0044]Working principle: When it is necessary to fix a product that needs to be electroplated, start the electric cylinder 13 to drive the electric rod 14 to move down, and the downward movement of the electric rod 14 will drive the moving plate 12 to move down, and the moving plate 12 will drive the moving rod 19 to move down, and the moving rod 19 moves down through the fixed shaft 18 and the first chute 192, so that the end of the hanging plate 191 is tilted, and people directly ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com