Automatic installation equipment and installation method of geothermal floor

An automatic installation and geothermal floor technology, which is applied in the direction of construction and building construction, can solve the problems of high paving cost, low work efficiency, poor paving accuracy, etc., and achieve the effect of high paving accuracy and reducing paving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

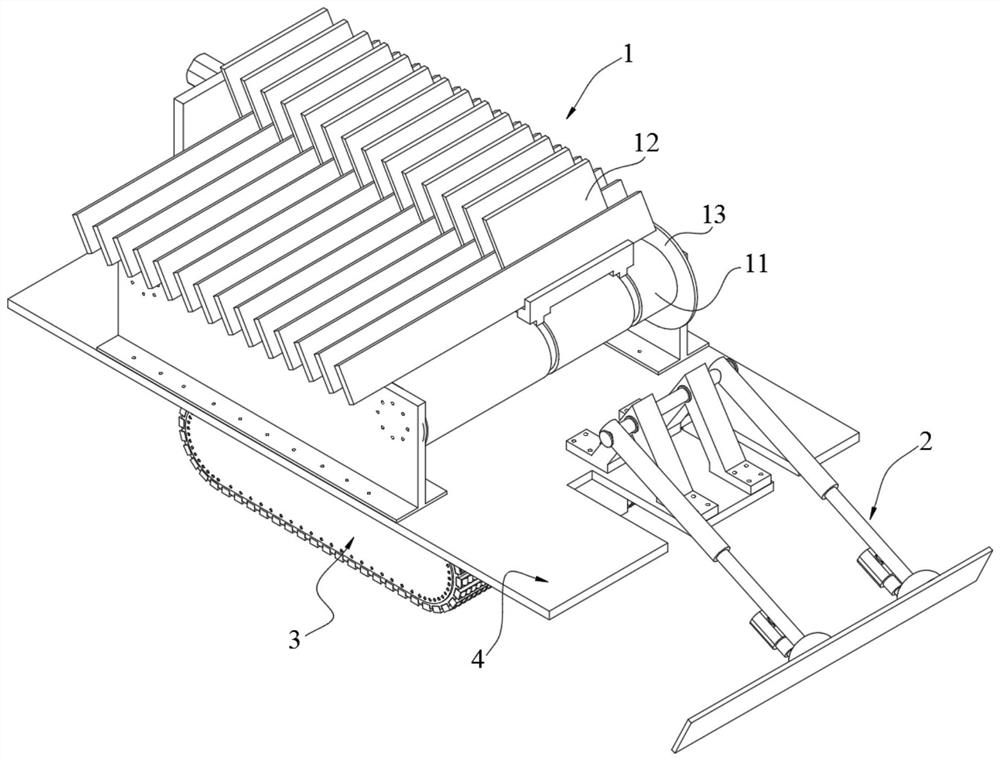

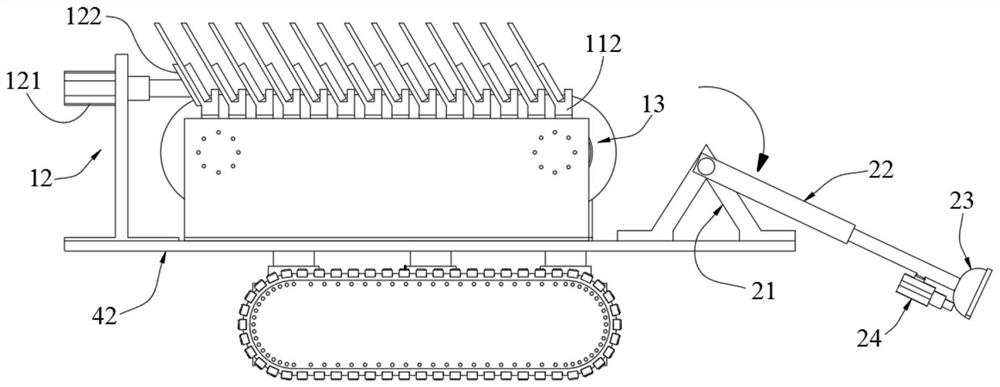

[0040] Example: Reference figure 1 The automatic installation equipment for self-adhesive flooring shown includes a feeding device 1, a paving device 2, a feeding device 3 that moves the feeding device 1 and the paving device 2 horizontally and vertically, and a control system. The feeding device 1 The paving device 2 is fixed on the feeding device 3 through the mounting seat 4, and the axes of the feeding device 1 and the paving device 2 coincide.

[0041] Mount 4

[0042]The mounting base 4 includes a base 41 fixedly connected to the feeding device 3 , a turntable 42 disposed on the base 41 , and a driving structure 43 for driving the turntable 42 to rotate relative to the base 41 . Wherein the driving structure 43 can be any structure in the prior art, for example, the base 41 is a hollow structure, the driving structure 43 is fixedly installed in the rotating motor in the base 41, and its extended end is fixedly connected with the turntable 42; or, Through gear transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com