High-altitude steel cantilever formwork support frame and construction method thereof

A formwork support and support frame technology, which is applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connector, and on-site preparation of building components to improve efficiency, reduce usage requirements, and reduce The effect of work difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

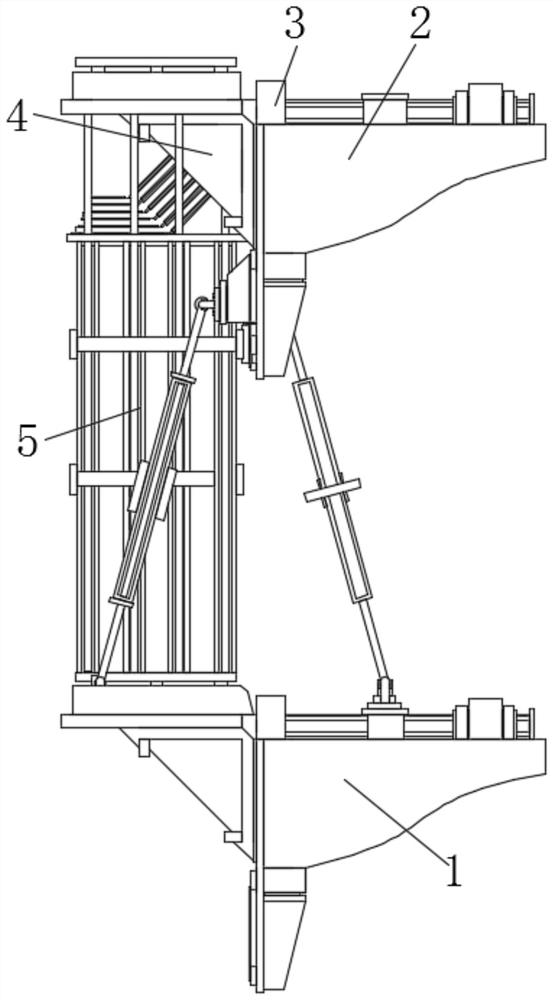

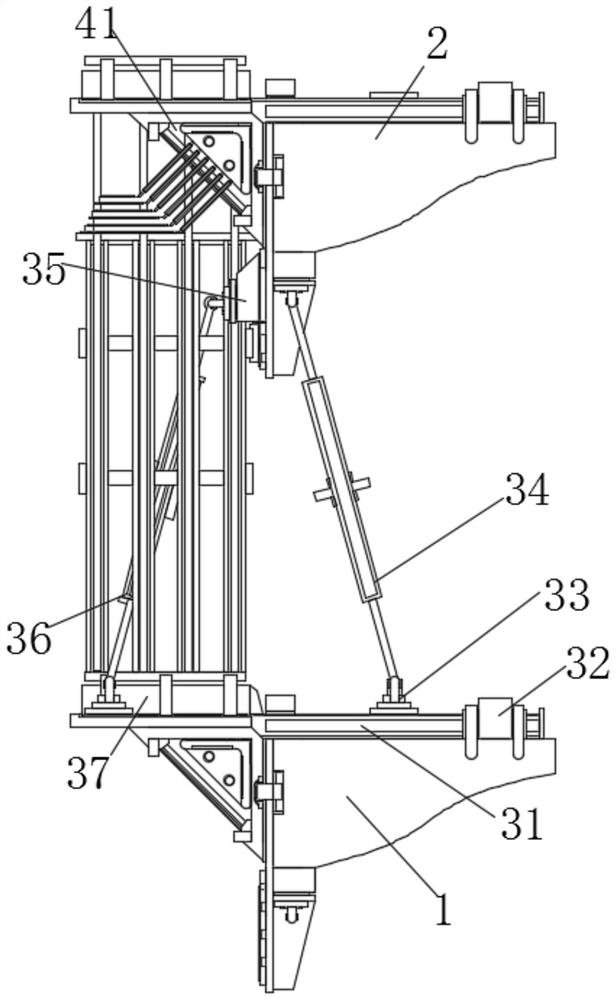

[0039] Example 1, such as Figure 1-3 As shown, when the support frame body 5 is erected to the inner side of the support platform 37, the support frame body 5 of a single node can be stably placed above the first beam body 1 under the system of the cantilever structure, and the support frame body 5 The upper direction extends to the second beam body 2. At this time, the positioning frame 43 set up under the triangular support seat 41 can be used as a connecting structure to promote the fixed connection between the positioning frame 43 and the supporting frame body 5, and further improve the connection system between the structures. and the stability of the integrated structure.

Embodiment 2

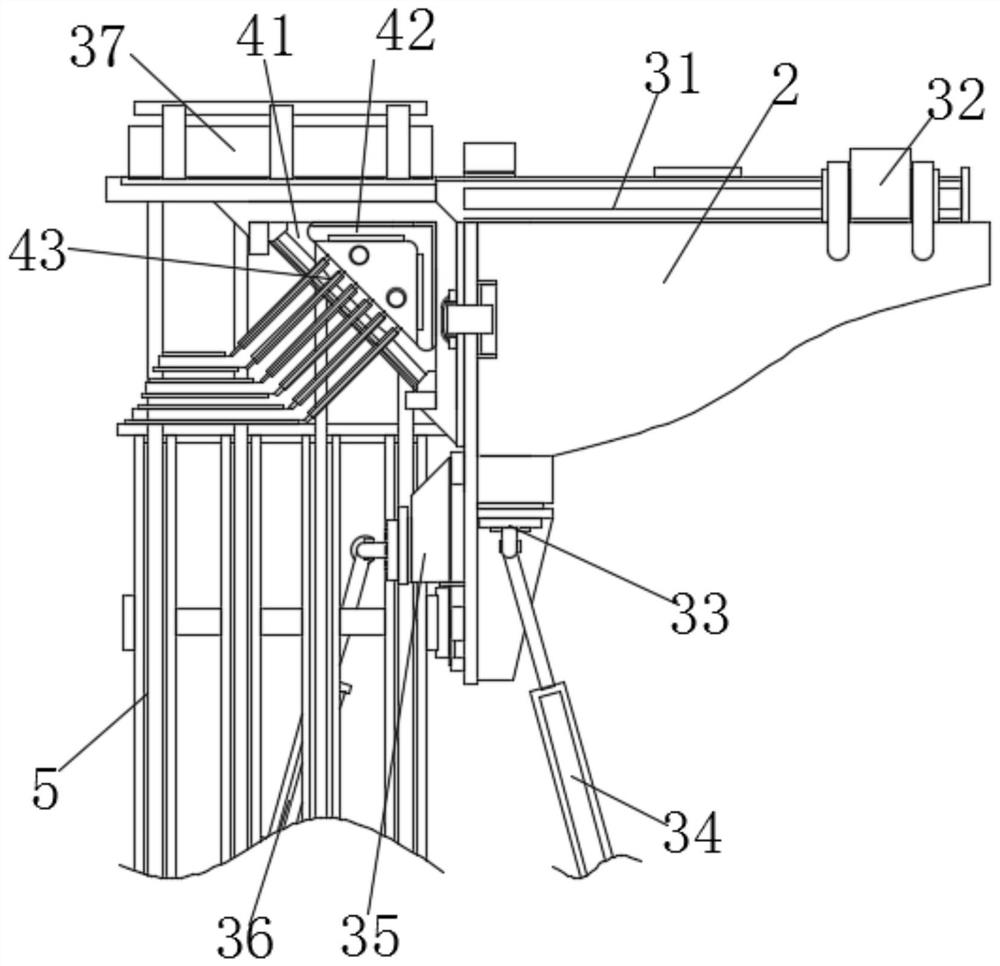

[0040] Example 2, such as Figure 4-5 As shown, when the two sets of triangular support bases 41 are assembled with the prefabricated structure through the scissor-type hinged rod 45 and the clamping plate 42, they can be guided and positioned through the positioning column of the clamping groove 44 and the positioning groove of the clamping plate 42. , increase the accuracy of the clamping plate 42 snapping into the inside of the clamping groove 44, improve the welding accuracy, and promote the movement adjustment between the scissor-type hinged rod 45 and the clamping plate 42 to be more stable, and use the inner sleeve 47 in The inner telescopic movement of the outer sleeve 46 is used as a guide system, so that the distance between the triangular support seat 41 is adjusted under the positioning of the clamping plate 42 and the clamping groove 44, and the auxiliary support plate 48 and the triangular support seat 41 are on the same horizontal plane to promote, The two sets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com