Split-flow regulation and control double-circulation coupling type high-temperature heat pump equipment

A high-temperature heat pump, coupled technology, applied in lighting and heating equipment, heat pump, heating water/sewage treatment, etc., can solve the problems of reducing processing efficiency, energy consumption, etc., to enhance processing efficiency, reduce usage, and strengthen fixed balance effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Figure 1 to Figure 6 Shown:

[0029] The invention provides a high-temperature heat pump equipment of split-flow regulation and dual-circulation coupling type,

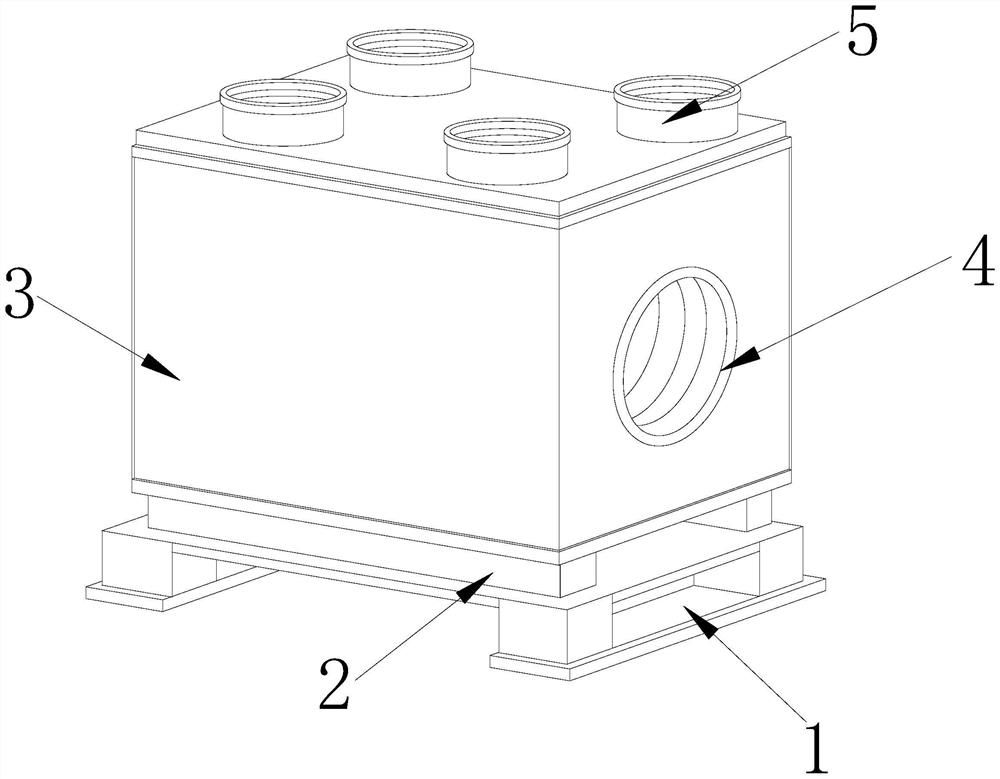

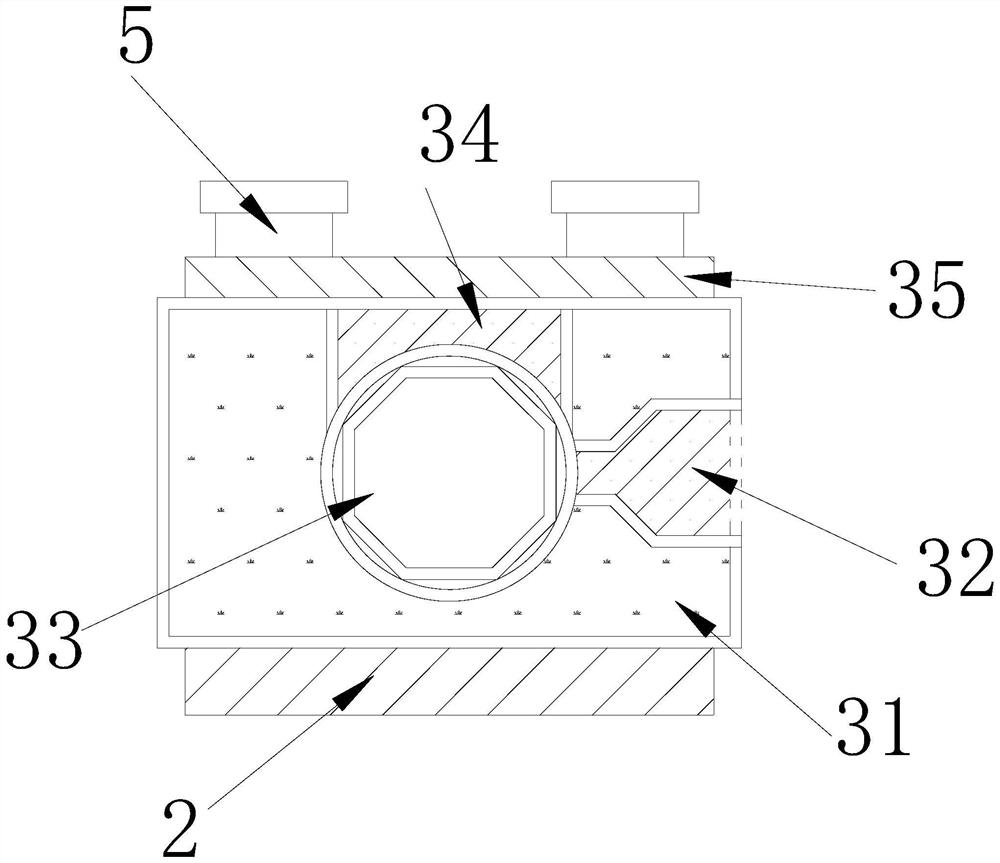

[0030] Its structure comprises, support seat 1, positioning block 2, processing box 3, connecting ring 4, distributing chimney 5, the upper end of described support seat 1 and the lower end of positioning block 2 fit together, the lower end of described processing box 3 and positioning block The upper end of 2 is fixedly connected, the connecting ring 4 is embedded in the side of the processing box 3, and the distribution chimney 5 is installed on the upper end of the processing box 3.

[0031] The processing box 3 is provided with an energizing end 31, a connecting channel 32, a compressor 33, an eruption shaft 34, and a dispersion layer 35. The energizing end 31 and the connecting channel 32 are in clearance fit, and the compressor 33 is embedded in the connecting channel 32. The side end of the eruption s...

Embodiment 2

[0039] Figure 7 to Figure 9 Shown:

[0040] The invention provides a high-temperature heat pump equipment of split-flow regulation and dual-circulation coupling type,

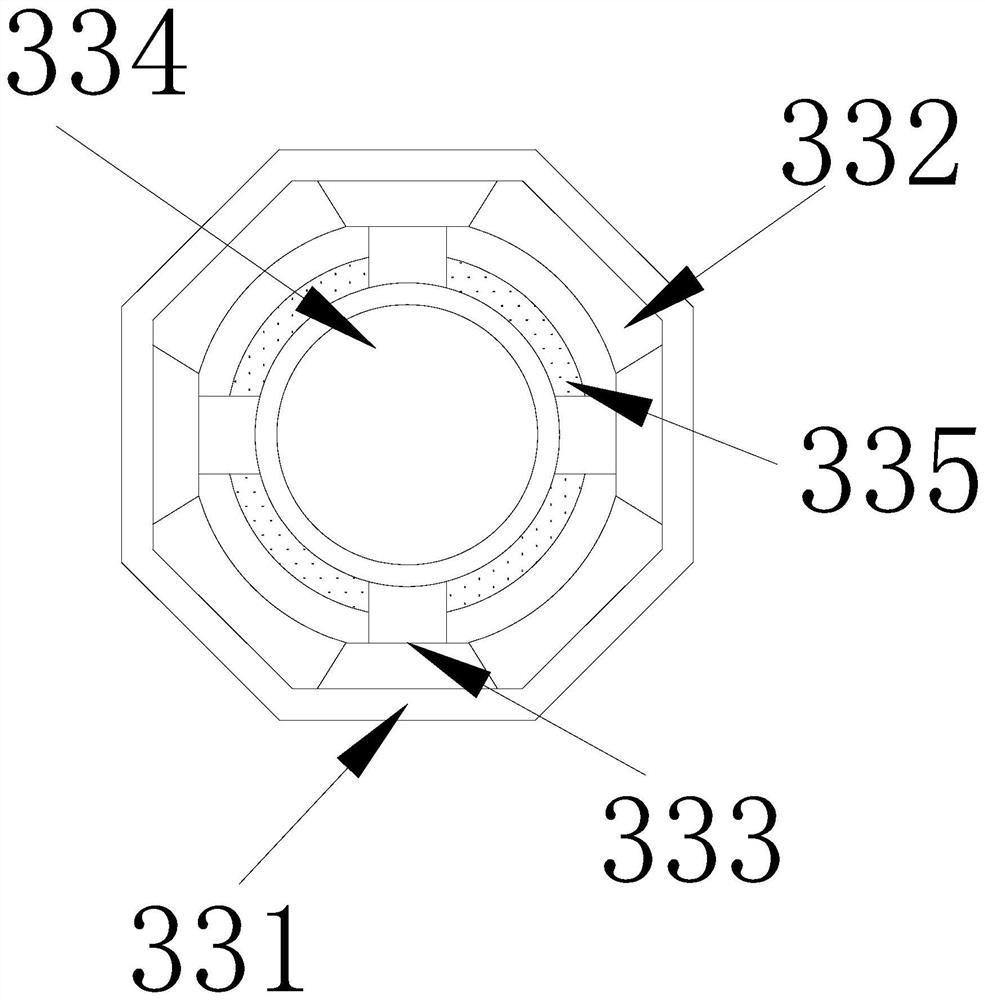

[0041] Its structure includes, the support rod 333 is provided with a connecting grid c1, a solid layer c2, and a lever c3, the connecting grid c1 is embedded in the solid layer c2, and the lever c3 is engaged with the lower end of the solid layer c2, The connecting grid c1 has an arc-shaped connecting grid and a square connecting grid, and the connecting grid c1 can effectively achieve a strengthened fixing effect and subsequent disassembly convenience to prevent stuck phenomena through two different connecting grids c1.

[0042] Wherein, the lower end of the lever c3 is provided with a limit ring c31, an interlayer c32, a fixed block c33, and a bolt plate c34. The limit ring c31 and the interlayer c32 are integrated, and the fixed block c33 is embedded in the interlayer c32. The bolt plate c34 is threadedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com