Method for improving precision of tire section scanning image

A cross-sectional scanning image and tire technology, which is applied to measuring devices, instruments, and optical devices, etc., can solve the problems of analysis result errors, failure to take into account, contour differences, etc., so as to improve the authenticity, improve accuracy, and make up for technical gaps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] A method for improving the accuracy of tire section scanning images, comprising the steps of:

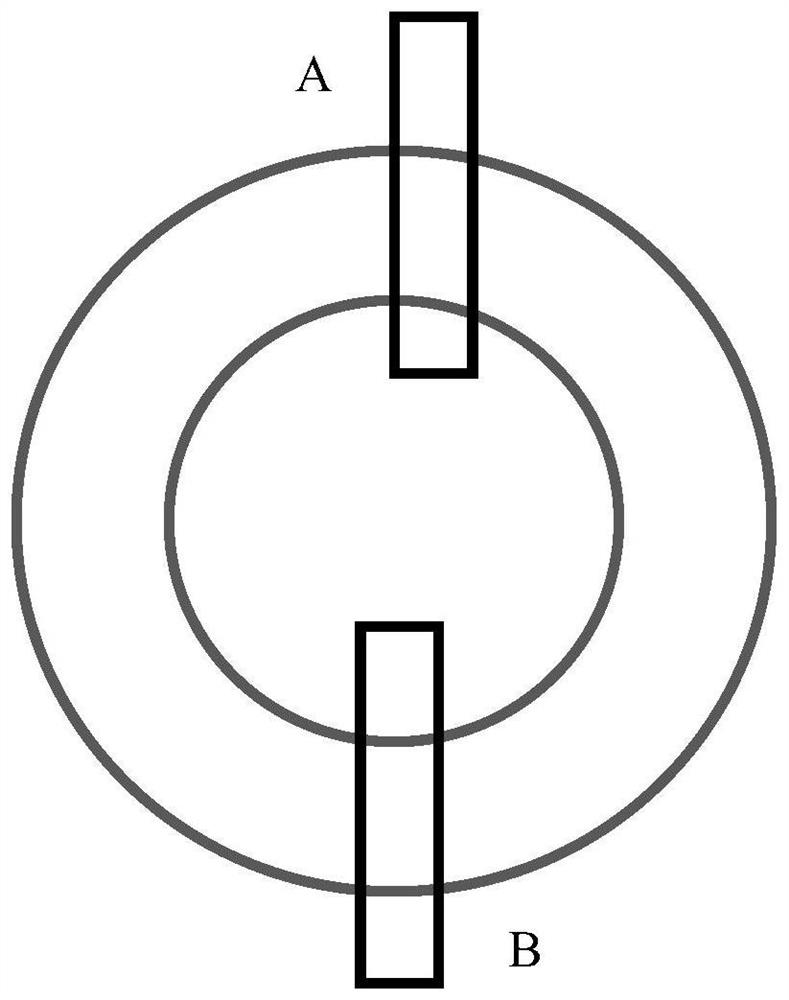

[0041] Such as figure 2 As shown, the first step: extract the tire contour line according to the tire design drawings. When the tire is a centrally symmetrical circle, extract the half-tire contour line; when the tire is non-centrosymmetrically circular, this situation is relatively rare. The outline of the whole tire needs to be extracted, and the extraction of the outline of the tire in this step can be performed by means of cad software.

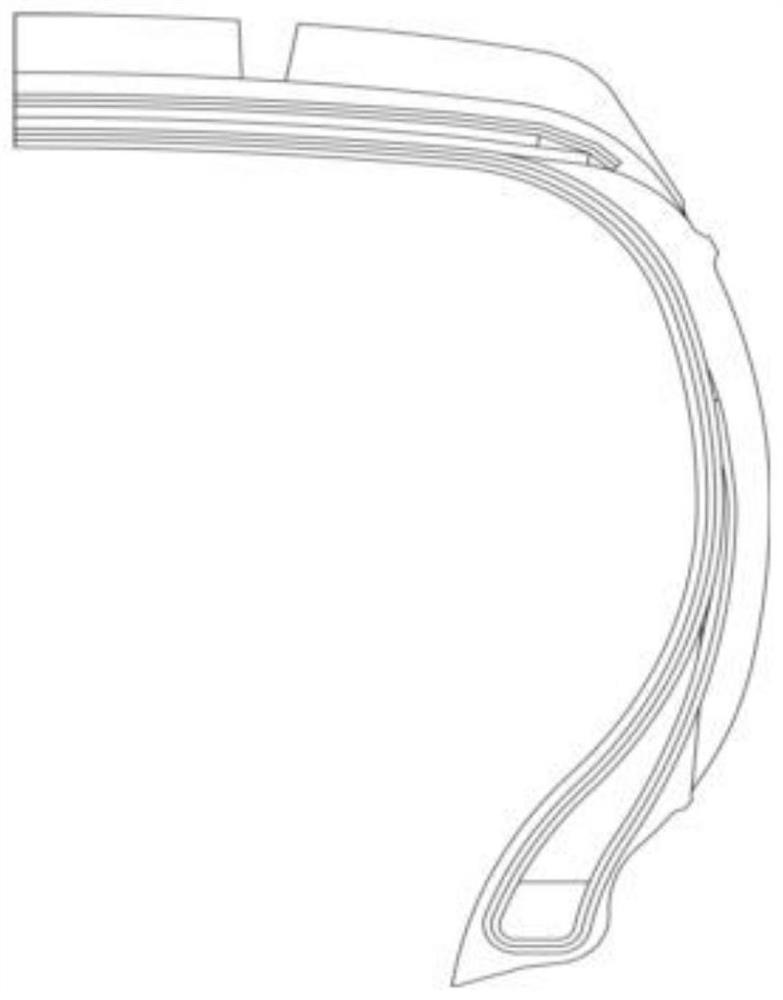

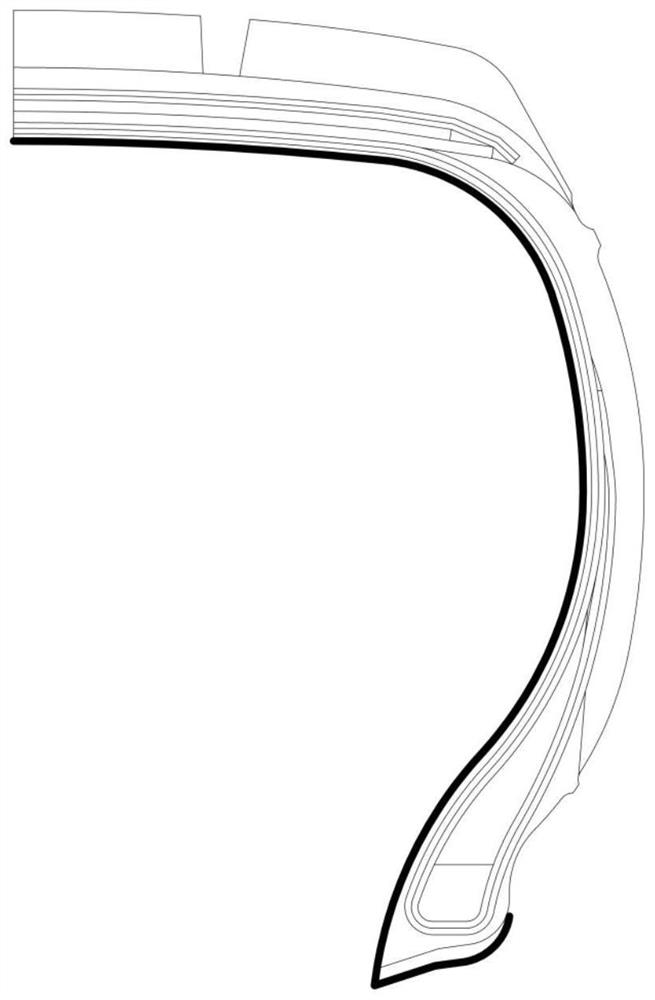

[0042] Such as image 3 and Figure 4 As shown, the second step: Import the tire outline obtained in the first step above into the 3D software. The tire itself has different structural layers, delete the outer outline, and only keep the inner outline, and then make a positioning fixture based on the inner outline ;

[0043] Such as image 3 , Figure 4 and Figure 5 As shown, the inner contour line obtained above includes the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com