Plug-in base of molded case circuit breaker

A molded case circuit breaker, plug-in technology, applied in the direction of circuits, parts of protective switches, electrical components, etc., can solve problems affecting the safety and reliability of equipment, unstable contact pressure, temperature rise, etc., to achieve temperature Excellent performance, reduced contact internal resistance, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

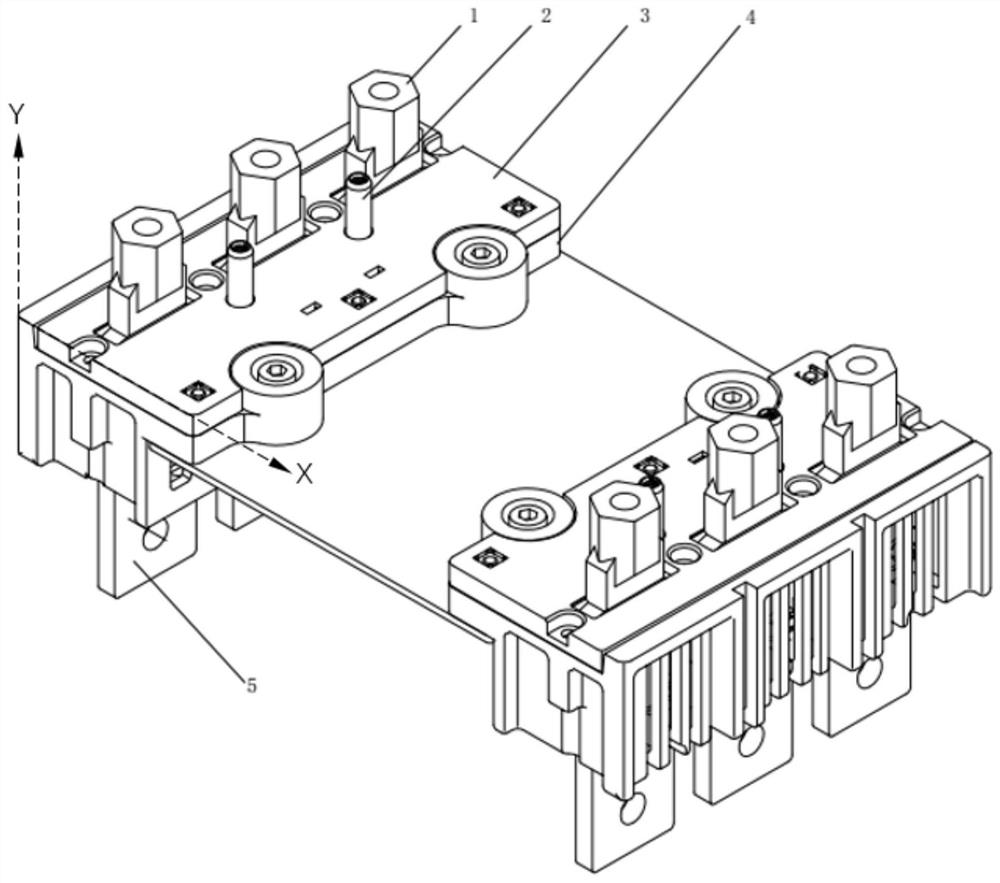

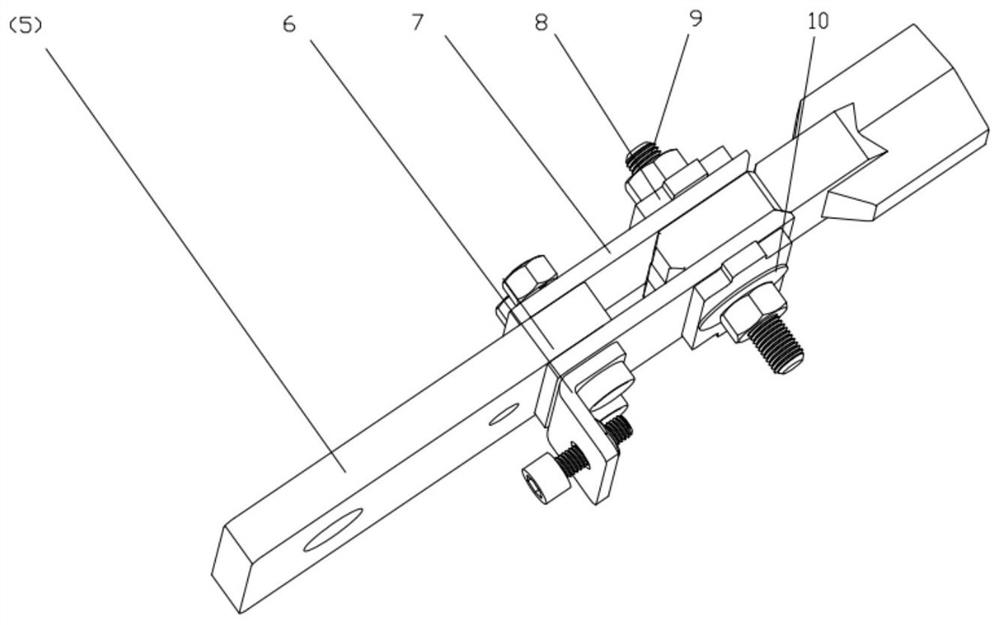

[0036] Such as Figure 1-11 The plug-in base of a molded case circuit breaker shown includes a plug 1, a fixed column 2, a cover 3, a base shell 4, an outer busbar 5, a fixed angle plate 6, a flexible connection plate 7, a pressure plate 8, a limit The rod 9 and the elastic member 10; the flexible connecting plate 7 is fixed to the outer busbar 5, and is installed on the base housing 4 through the fixed angle plate 6; the limit rod 9 passes through the elastic member 10, the pressure plate 8, and the flexible connecting plate 7, Placed in the base shell 4; the cover 3 is provided with a limit rod 9 and fastened with the base shell 4; the flexible connecting plate 7 can move in the base shell 4, when the plug 1 and the flexible connecting plate 7 are plugged When connecting, the plug 1 can automatically adjust the alignment to align with the gap between the two flexible connecting plates 7, and the plug 1 pushes and compresses the elastic member 10 to generate a clamping force,...

Embodiment 2

[0038] Such as Figure 12 A plug-in base of a molded case circuit breaker is shown, including a plug 1, a connector 11, a peripheral support structure 12 of the connector, and an outer busbar 5; the plug-in base is provided with a peripheral support structure 12 of the connector, and the peripheral support structure of the connector 12 is provided with a connector 11, and the plug 1 is connected to the outer busbar 5 through the connector 11; the connector 11 is set as an elastic connector, and the peripheral supporting structure 12 of the connector around the elastic connector is provided with a The position-limiting structure restricts the movement of the elastic connector in the second direction Y, prevents the movement of the connector in the second direction Y and affects the connection effect, the guiding structure for guiding the movement of the elastic connector and the movement of the elastic connector Space. The elastic connector includes a flexible connecting plate...

Embodiment 3

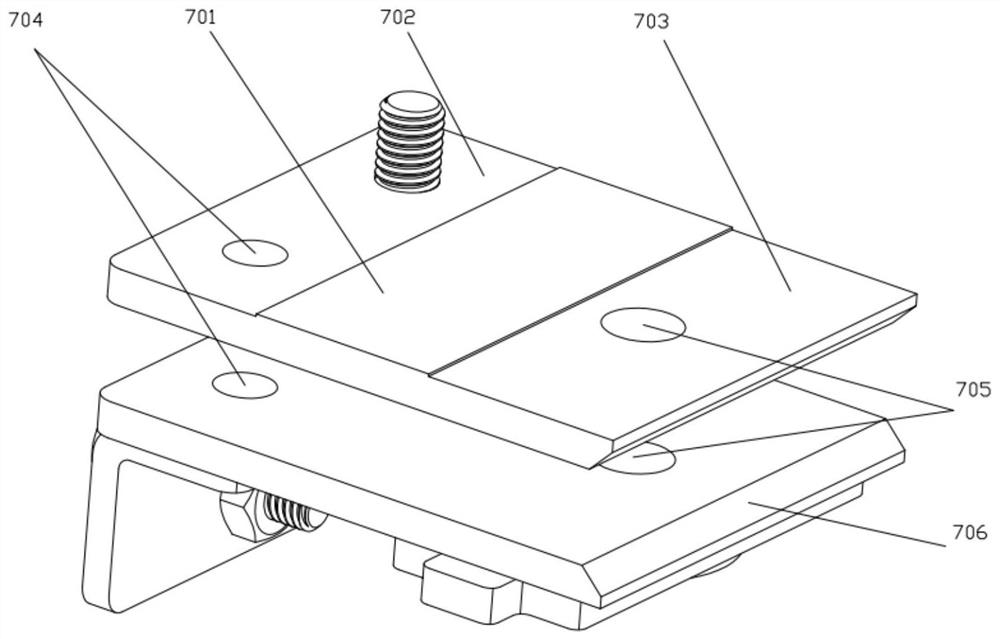

[0040] Such as Figure 13 A plug-in base of a molded case circuit breaker is shown, including a plug 1, a connector 11, a peripheral support structure 12 of the connector, and an outer busbar 5; the plug-in base is provided with a peripheral support structure 12 of the connector, and the peripheral support structure of the connector 12 is provided with a connector 11, and the plug 1 is connected to the outer busbar 5 through the connector 11; the connector 11 is set as an elastic connector, and the peripheral supporting structure 12 of the connector around the elastic connector is provided with a The limit structure, the guide structure for guiding the movement of the elastic connector and the space for the elastic connector to move. The elastic connector includes a flexible connecting plate 7; the flexible connecting plate 7 includes a flexible part 701, an outer busbar connecting part 702 and a plug connecting part 703; a flexible part 701 is provided between the outer busba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com