Cottonseed delinting device convenient to clean

A cottonseed and installation block technology is applied in the field of cottonseed delinting, which can solve the problems of increased work force by staff, affecting the effect of cottonseed delinting, and inability to guarantee the effect, so as to reduce the difficulty of operation, improve the effect of cleaning, and simplify the cleaning. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

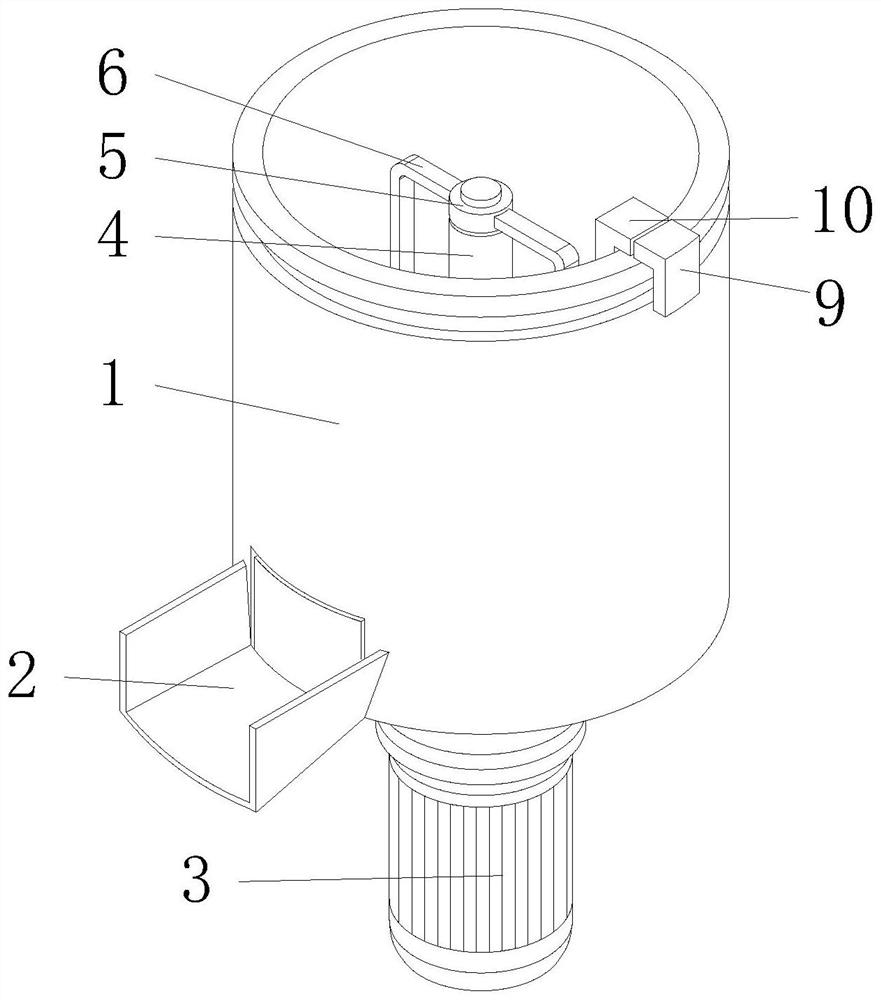

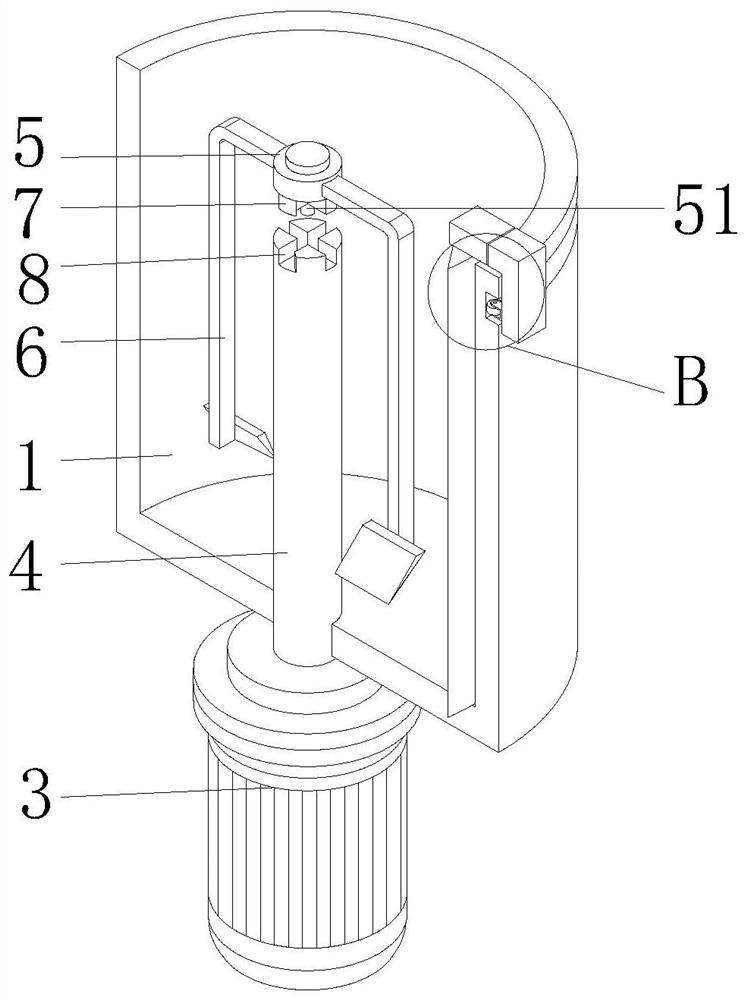

[0033] Example 1: See Figure 1-Figure 6 , a cottonseed delinting device that is easy to clean, comprising a barrel body 1, the outer surface of the barrel body 1 is provided with a seed outlet 2, and the seed outlet 2 places are respectively provided with inclined plates and baffles, and the lower surface of the barrel body 1 is fixed A driving motor 3 is connected, and the bottom inner wall of the barrel body 1 is rotatably connected with a rotating shaft 4 whose lower end penetrates the lower surface of the barrel body 1 and is fixedly connected with the output shaft of the driving motor 3. The upper end of the rotating shaft 4 is provided with a mounting block 5, which The outer surface of the block 5 is respectively fixedly connected with two stirring arms 6 which are arranged as mirror images, so the rotating shaft 4 is synchronously driven by the drive motor 3 to rotate, so that the stirring arm 6 rotates in the barrel body 1 and the cottonseed in the barrel body 1 Stir...

Embodiment 2

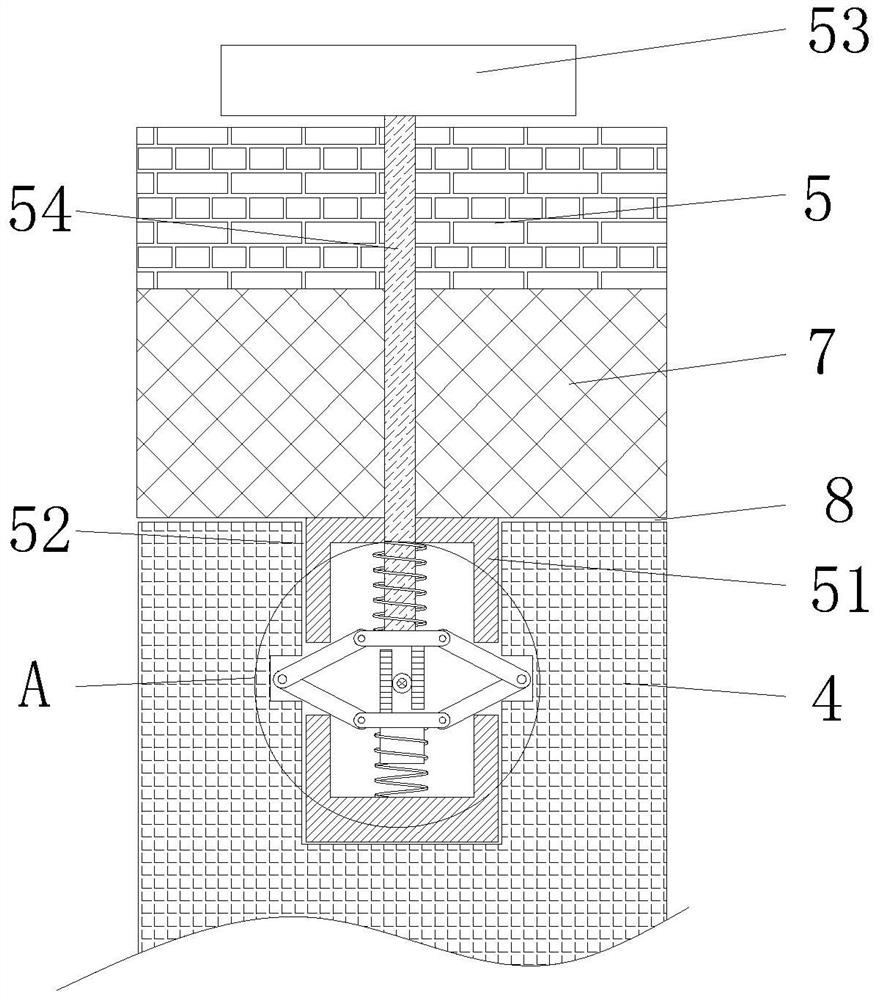

[0043] Example 2: See Figure 5-Figure 6 , the second embodiment is to make a corresponding improvement on the basis of the first embodiment. Further, the barrel body 1 is provided with a first mounting block 9 and a second mounting block 10 respectively, and the lower surface of the second mounting block 10 is fixed The scraper 11 is connected to the inner wall of the barrel body 1, and the scraper 11 is set in an arc shape, so the second installation block 10 is pushed to drive the scraper 11 to slide along the inner wall of the barrel body 1, so that the scraper 11 is aligned with the barrel. The residual impurities on the inner wall of the barrel body 1 are scraped off, which simplifies the cleaning operation of the staff on the inner wall of the barrel body 1 and improves the cleaning effect on the inner wall of the barrel body 1 at the same time.

[0044] Further, on the side surface of the first mounting block 9 facing the second mounting block 10, a pull rod 14 whose o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com