Brush roll connecting piece and milling device thereof

A technology of milling device and connector, applied in milling machine equipment, details of milling machine equipment, metal processing equipment, etc., can solve the problems of low efficiency and labor consumption, and achieve the effects of simple fixing, fast connection speed and stable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

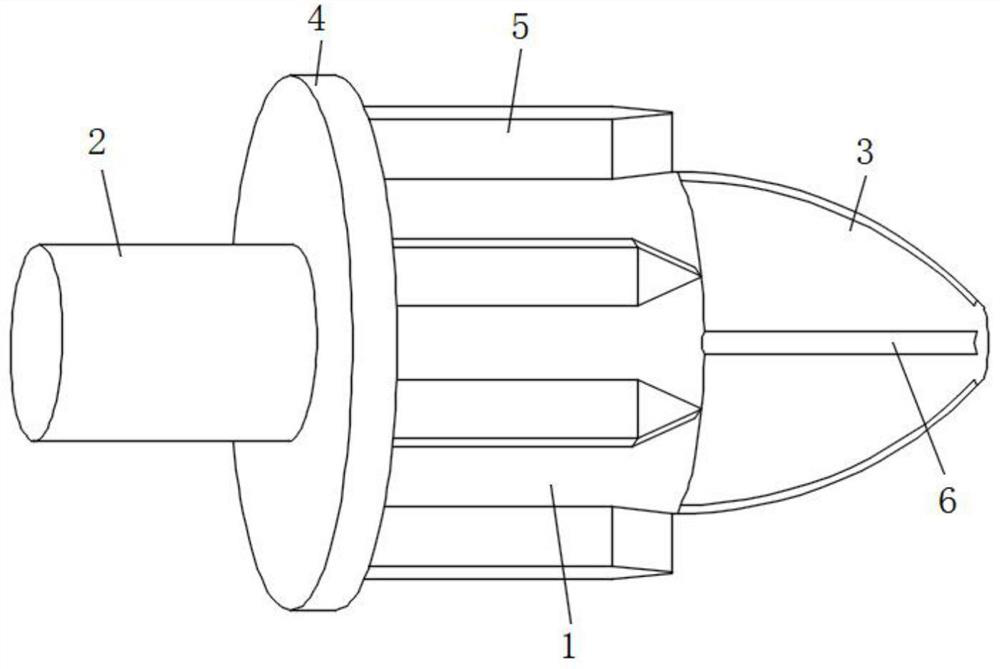

[0033] refer to Figure 1-6 , a brush roller connector, including a snap-in post 1, a drive connection shaft 2 and a guide cone 3 are respectively arranged on both sides of the snap-in post 1, and a limit position is also provided on the outer wall of the joint between the drive connection shaft 2 and the snap-in post 1 The sheet 4, the outer wall of the clamping column 1 is also provided with a clamping strip 5, and the guide cone 3 is also provided with an arc-shaped groove 6.

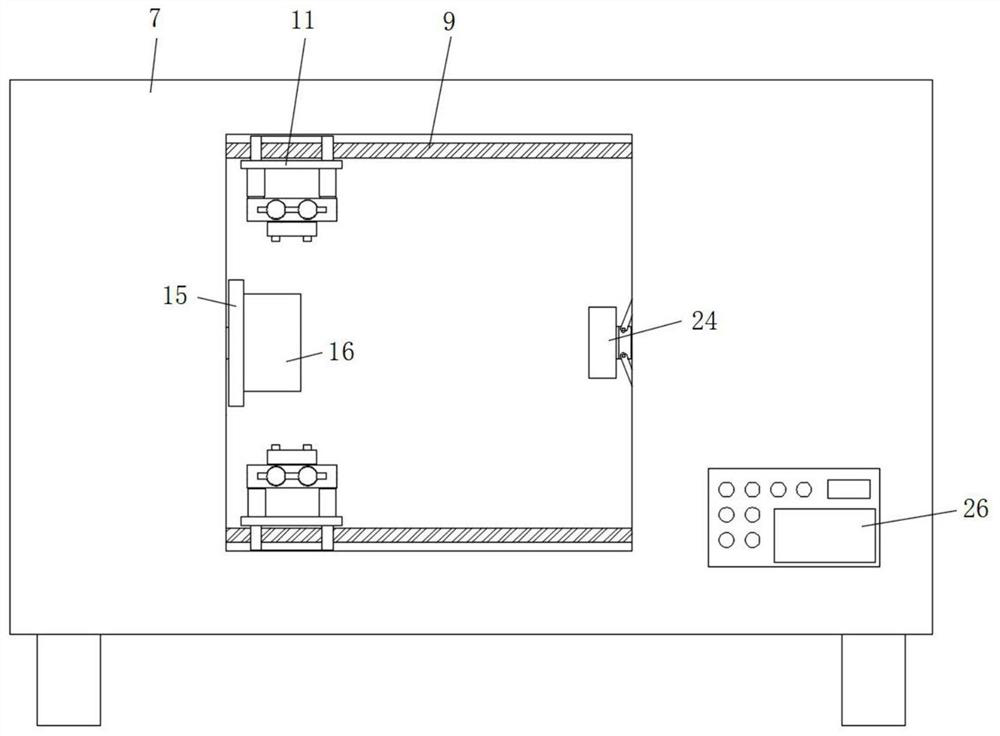

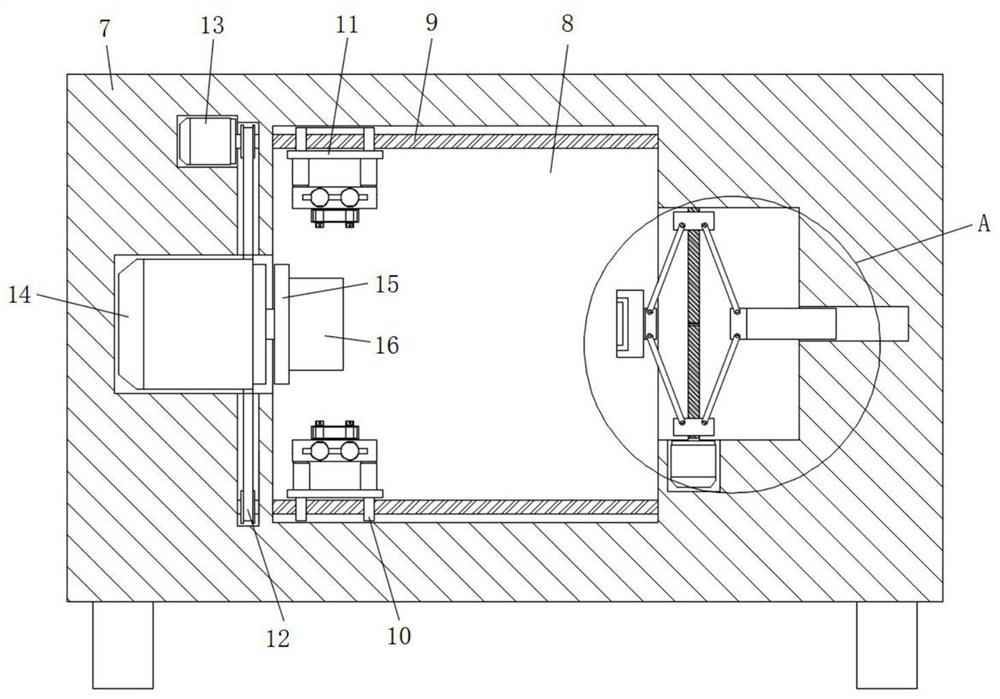

[0034]A milling device for brush roller connectors, the milling device includes a working box 7, a rectangular hole 8 is opened through the front and rear sides of the middle part of the working box 7, and threaded rods are rotatably connected between the upper and lower side walls of the rectangular hole 8 9. The outer wall of the threaded rod 9 is threadedly connected with a mounting sleeve 10, and the upper and lower side mounting sleeves 10 are fixed with a milling assembly 11. One side of the re...

Embodiment 2

[0036] Such as figure 1 As shown, this embodiment is basically the same as Embodiment 1. Preferably, there are a plurality of clamping strips 5 and are annularly distributed on the outer wall of the clamping column 1, and four arc-shaped grooves 6 are provided and are evenly distributed in a circular shape. On the outer wall of the guide cone 3, the diameter of the clamping column 1 matches the inner diameter of the brush roller body, and a plurality of slots matching the clamping strips 5 are provided on both sides of the brush roller body.

[0037] In this embodiment, both sides of the brush roller body are provided with a plurality of slots that match the clamping strips 5 , so that the connection between the brush roller connector and the brush roller body is more stable.

Embodiment 3

[0039] Such as Figure 5 with 6 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the milling assembly 11 includes a connecting plate 111, which is fixedly connected to the mounting sleeve 10, and both sides of the connecting plate 111 near the rectangular hole 8 are fixed by screws. An electric telescopic rod one 112, the output end of the electric telescopic rod one 112 is fixed with an installation box 113, the inner wall of the rear end of the installation box 113 is fixed with an electric telescopic rod two 114, and the output ends of the electric telescopic rod two 114 are all fixedly connected with a sliding block 115 by screws, The bottom surface of the installation box 113 is also provided with a sliding groove, and the sliding blocks 115 are all slidably connected in the sliding groove. The screw is fixed with the electric telescopic rod three 117, and the output end of the electric telescopic rod three 117 extends to the outer wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com