Welding quality real-time detection method and system based on LSTM and residual distribution

A welding quality, real-time detection technology, applied in welding equipment, high-frequency current welding equipment, biological neural network models, etc. , The effect of low detection cost and not easy to be affected by environmental factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings, and the technical solution of the present invention will be explained more clearly and completely.

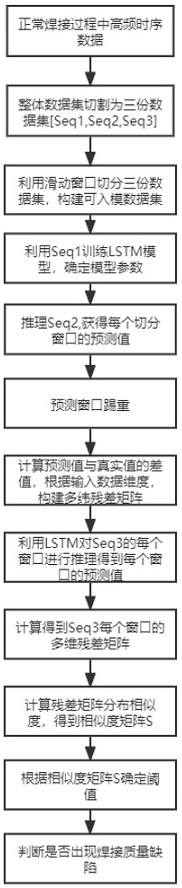

[0025] Such as figure 1 Shown is a real-time detection method of welding quality based on LSTM and residual distribution, including the following steps:

[0026] Step 1: Obtain the high-frequency current and voltage time series data in the normal welding process;

[0027] The data here is to use non-invasive data acquisition equipment to collect high-frequency current and voltage data during a long period of time in the normal welding process;

[0028] Step 2: Split the collected high-frequency current and voltage time-series data into three data sets with the same amount of data, which are used for model training, construction of residual matrix, and determination of welding quality defect thresholds;

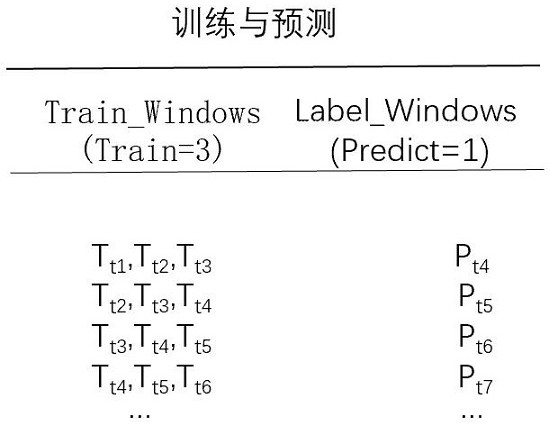

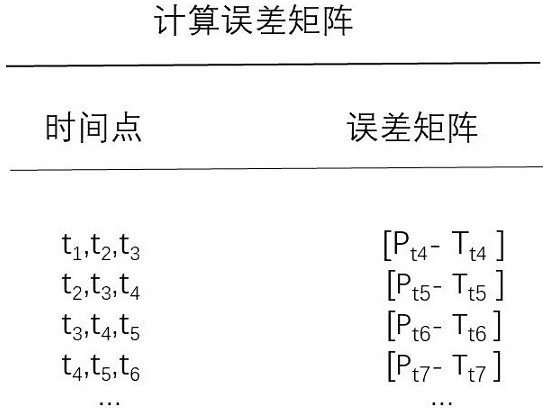

[0029] Step 3: Carry out the above three data set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com