Material transfer device for earthwork roadbed construction

A transfer device and roadbed technology, which is applied in transportation and packaging, processing of building materials, trolleys, etc., can solve the problems of inability to completely pour out transfer materials and cannot be applied to the fast-paced transfer environment, so as to avoid construction accidental injuries and perfect functions , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

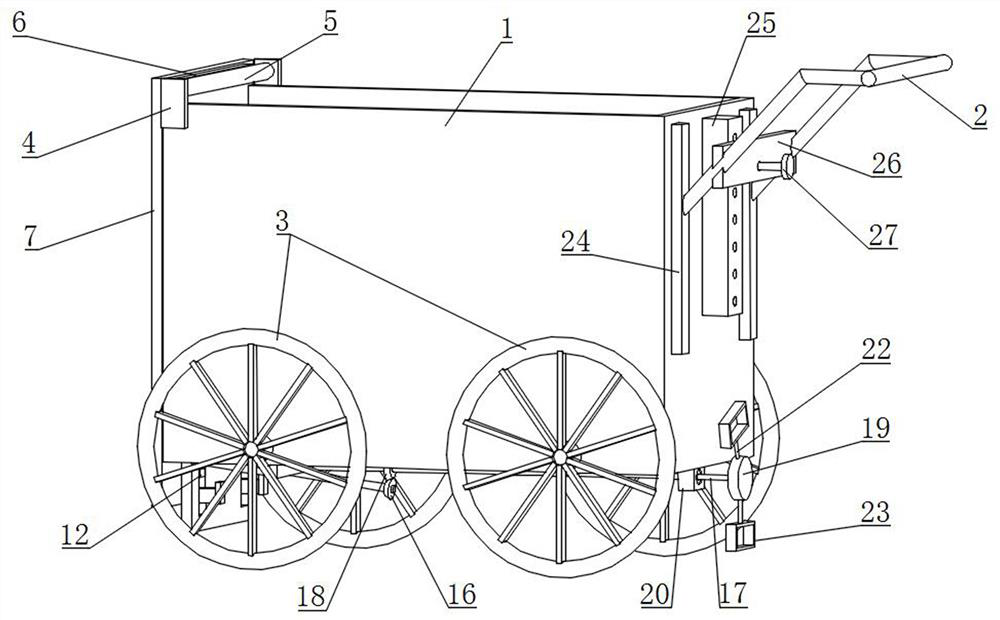

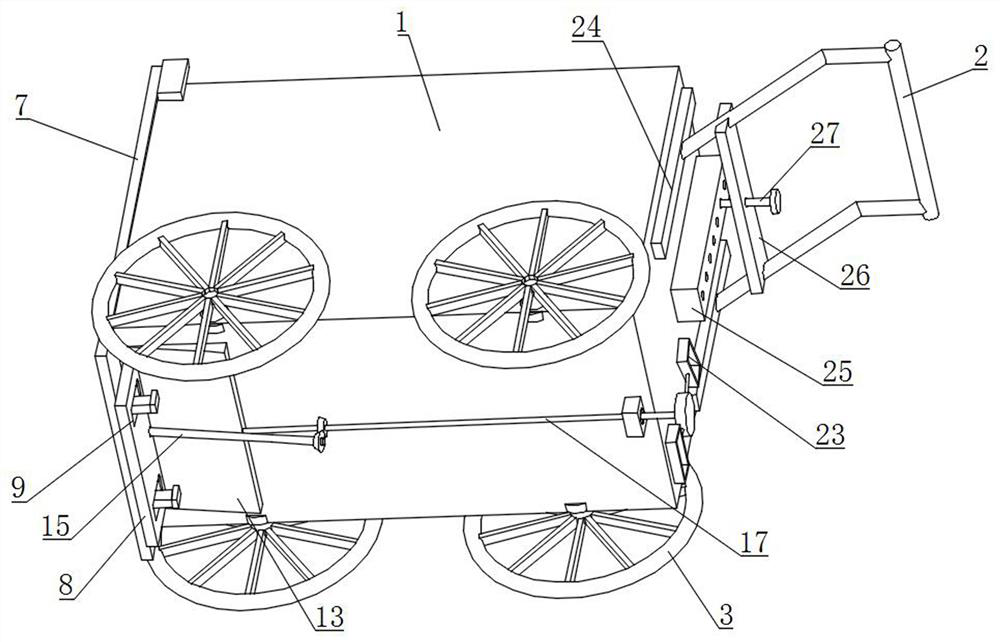

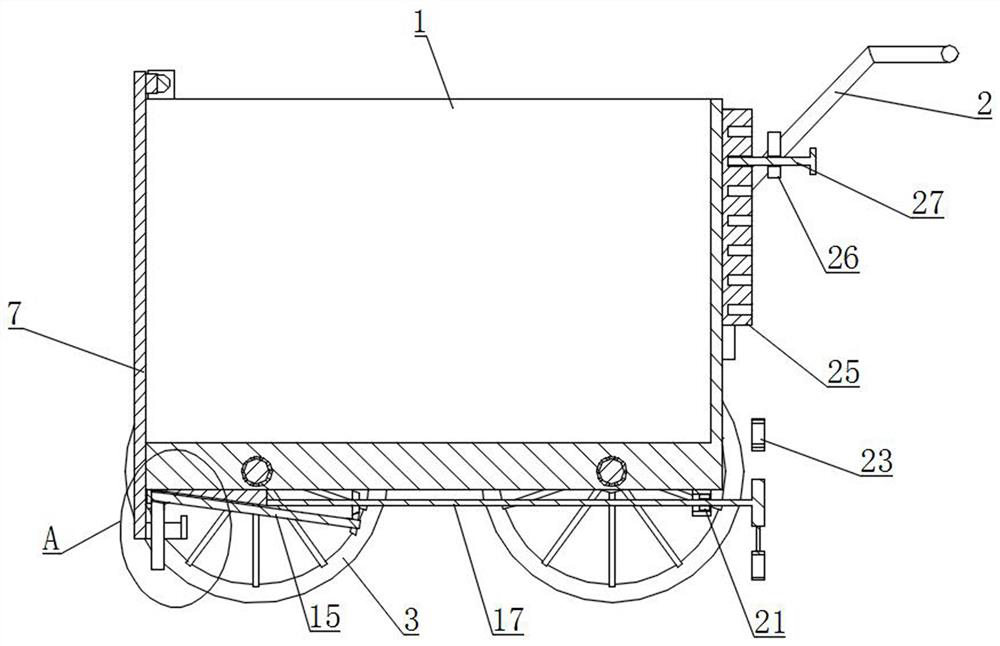

[0026] The main structure of this embodiment, such as Figure 1~4 As shown, the transfer box 1, the slide plate 8, the insertion rod 10, the first limiting plate 11, the second limiting plate 12, the triangular guide plate 13, the fixing block 14 and the screw rod 15;

[0027] The top and the front side of the transfer box 1 are all open, the left and right sides of the bottom of the transfer box 1 are rotated to set two sets of rollers 3, the rear side of the transfer box 1 is provided with a push handle 2, and the top of the front end of the transfer box 1 is rotated to close the front opening. Sealing plate 7, the rotation direction of the sealing plate 7 is clockwise or counterclockwise, the bottom of the sealing plate 7 is located below the transfer box 1; the triangular guide plate 13 is arranged at the bottom of the transfer box 1, and the shape of the transverse section of the triangular guide plate 13 is a right angle Triangular, the hypotenuse of the right triangle i...

Embodiment 2

[0030] In this embodiment, on the basis of the foregoing embodiments, a slide rail 24, a second support plate 25, a third support plate 26 and bolts 27 are further added, as Figure 1~3 As shown, the slide rail 24 is vertically arranged on the outer wall of the rear side of the transfer box 1, and two groups of slide rails 24 are arranged, and the push handle 2 is slid and arranged on the slide rail 24 along the vertical direction; the second support plate 25 is vertically arranged on the outer wall of the rear side of the transfer box 1, and the second support plate 25 is located between two groups of slide rails 24; the third support plate 26 is arranged on the push handle 2, and the third support plate 26 and the transfer box 1 The rear side outer wall is parallel, threaded holes b are set on the third support plate 26, and multiple groups of threaded holes b are arranged side by side on the second support plate 25; the bolts 27 are matched with the threaded holes b, and the...

Embodiment 3

[0032] On the basis of the above embodiments, this embodiment further defines the structure of the rotating assembly, as shown in 1-3s, the rotating assembly includes a first bevel gear 16, a second support rod 17, a second bevel gear 18, a circular Plate 19 and the third support rod 22; the first bevel gear 16 is arranged on the screw rod 15, and the first bevel gear 16 is located at the rear side of the triangular guide plate 13; the second support rod 17 is horizontal and rotated and arranged on the triangular guide plate 13, the second support rod 17 is located between the first bevel gear 16 and the bottom of the transfer case 1, and the right end of the second support rod 17 is located at the rear side of the transfer case 1; the second bevel gear 18 is arranged on the second support rod 17 , the second bevel gear 18 meshes with the first bevel gear 16; the disc 19 is arranged on the right end of the second support rod 17; the third support rod 22 is arranged on the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com