#-shaped wheel set mechanism

A wheel set and tic-tac-toe technology, which is applied in the field of metal surface treatment, can solve the problems of tic-tac-toe wheel set blockage, affect processing efficiency, interfere with processing, etc., and achieve the effect of reducing time-consuming and labor-intensive and increasing production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

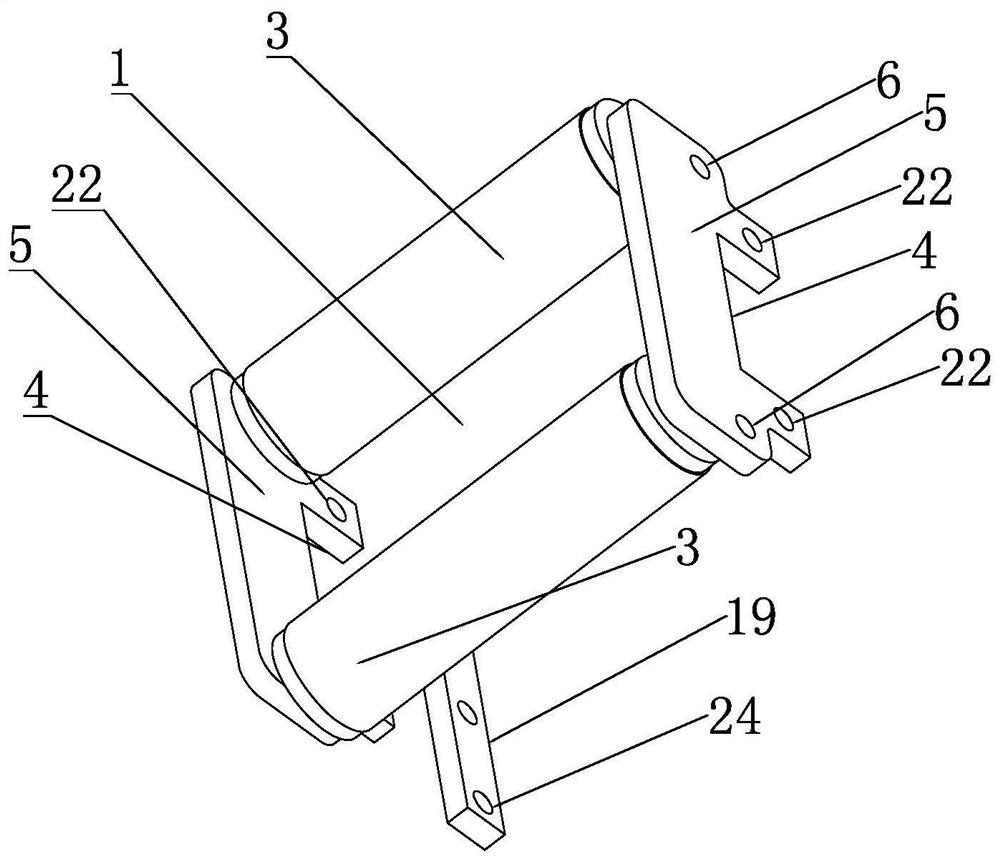

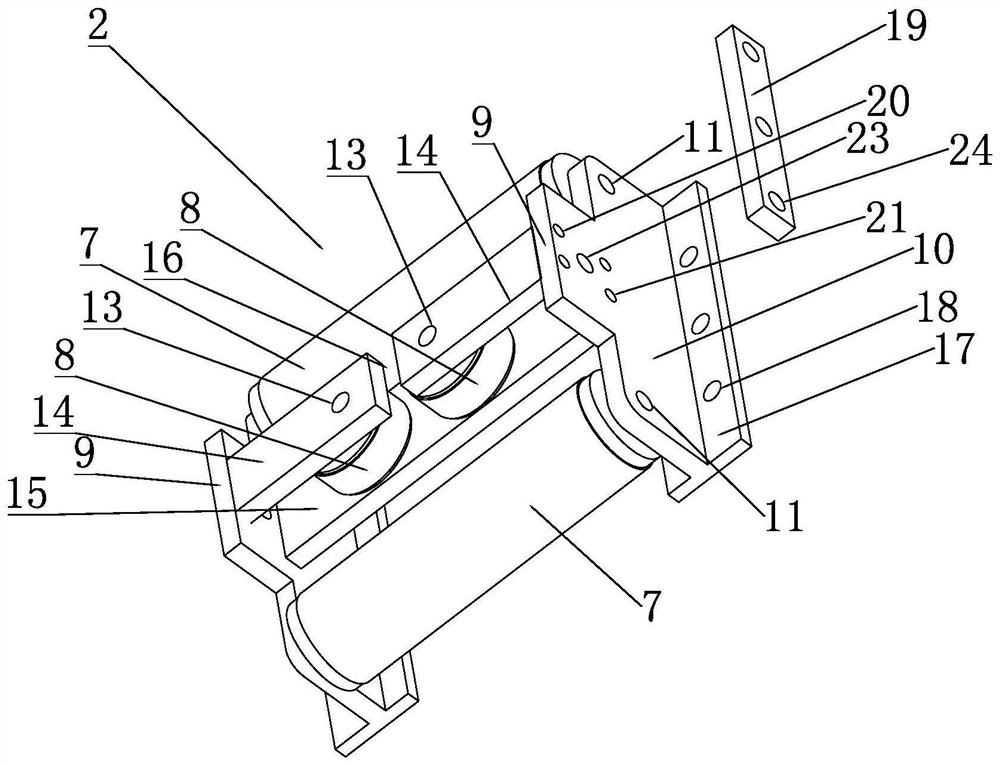

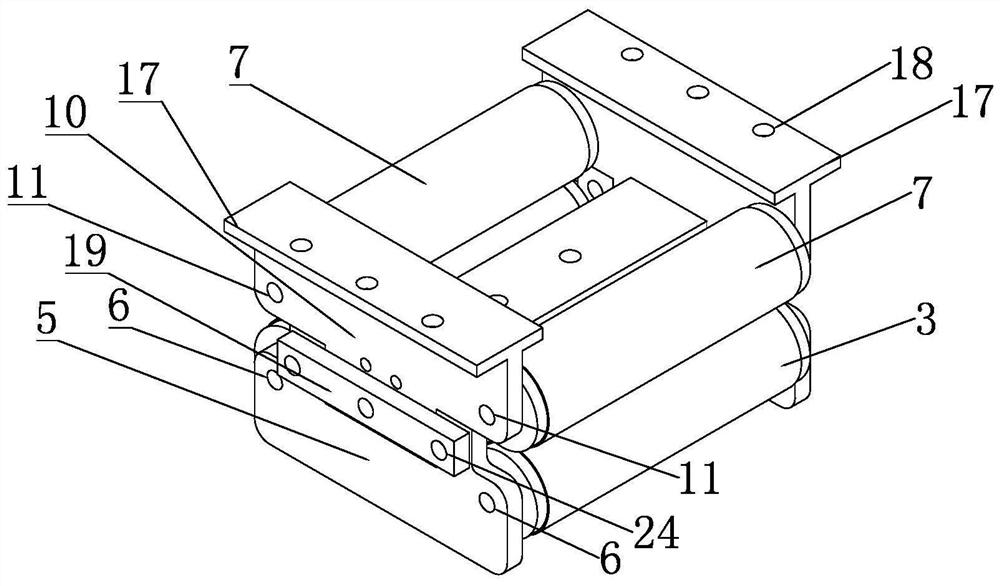

[0028] Example: as Figure 1-10 As shown, a well-shaped wheel set mechanism of the present invention includes such as figure 1 The first round shown in Group 1 and as figure 2 Second wheel set 2 shown.

[0029] like figure 1 As shown, the first wheel set 1 includes a pair of first rollers 3 and two oppositely arranged first mounting plates 5; the first rollers 3 are arranged at intervals and are respectively rotatably connected with the first mounting plates 5, so Each of the first mounting plates 5 is provided with a groove 4, two first mounting holes 6 and two first assembly threaded holes 22, and the groove 4 is concave inward in the middle of one side of the first mounting plate 5. The groove 4 is a square shape, the first roller mounting holes 6 are provided on both sides of the bottom of the groove 4 , and the first assembly threaded holes are provided on both sides of the upper part of the groove 4 . The two first rollers 3 are mounted between the two first mountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com