Additive manufacturing structured light loopback detection method and device, electronic equipment and storage medium

A technology of additive manufacturing and structured light, which is applied in the direction of measuring devices, optical devices, image data processing, etc., can solve the problems of consuming a lot of time and computing resources, registration residuals, and negative impacts on measurement efficiency, and achieves improved targeted performance, good industrial value, and the effect of reducing the amount of calculation and data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] The embodiments of the present disclosure propose a method, device, electronic device, and storage medium for additively manufactured structured light loopback detection, which are further described in detail below with reference to the accompanying drawings and specific embodiments.

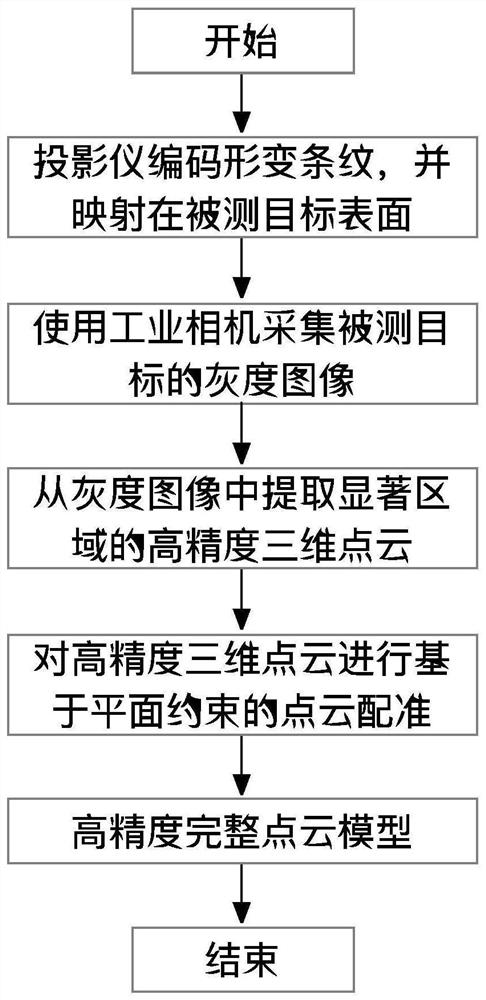

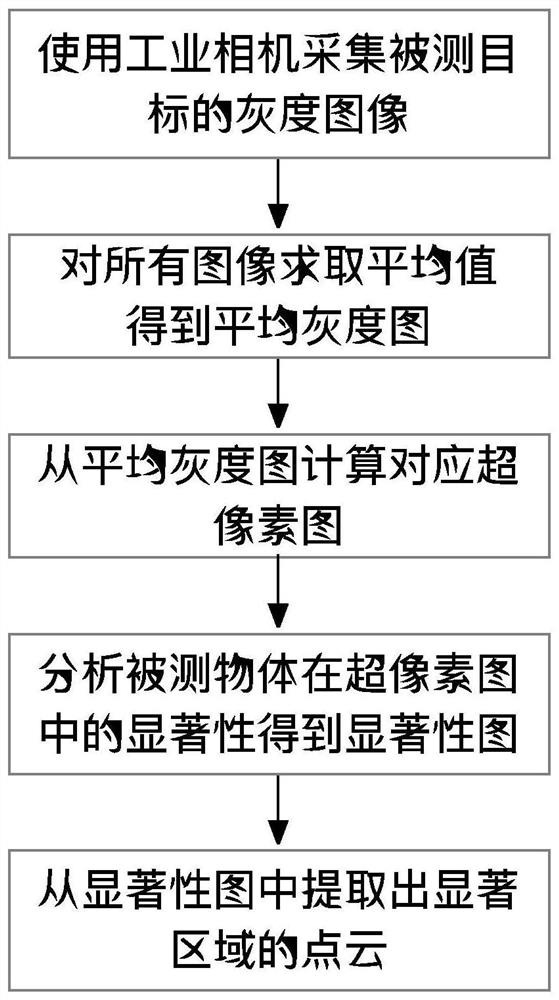

[0091] The embodiment of the first aspect of the present disclosure proposes a method for detecting a loopback of an additive manufacturing structure light. The overall process is as follows figure 1 shown, including the following steps:

[0092] (1) Use the additively manufactured substrate as the target to be tested;

[0093] (2) Using a structured light measurement system to obtain a sequence of structured light encoded fringe images mapped on the surface of the measured target. The structured light measurement system described in the embodiments of the present disclosure adopts a conventional system; preferably, in some embodiments of the present disclosure, phase shift coding is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com