Pneumatic test experiment table with pipeline management structure

A technology for testing experiments and test benches, applied in pump testing, mechanical equipment, machines/engines, etc., can solve the problems of resource waste, time consumption, oil pollution test benches, etc., to facilitate disassembly and replacement, and reduce shaking frequency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

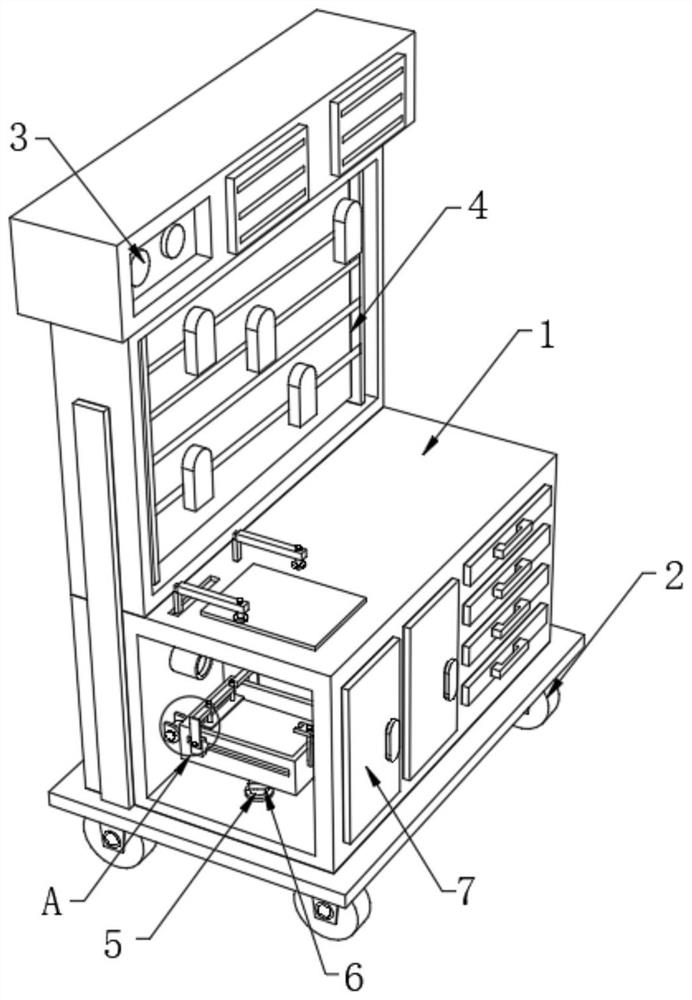

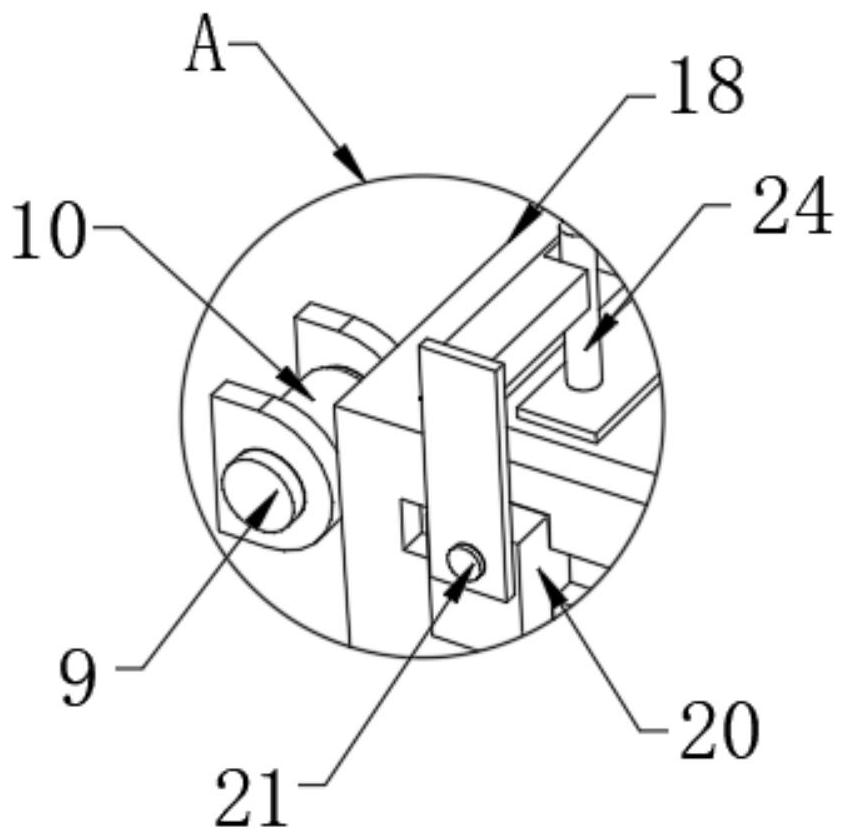

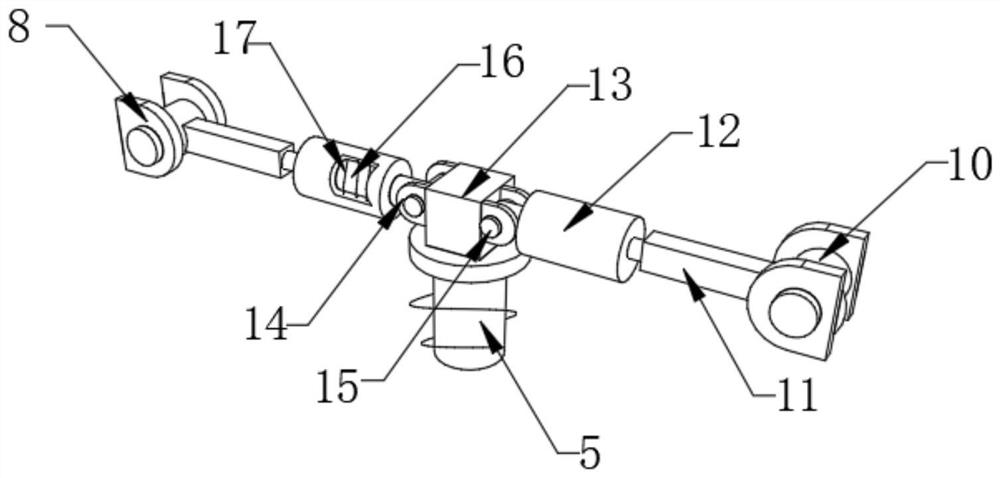

[0029] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, including the test bench body 1, universal wheels 2, control panel 3 and movable box 4, the four corners of the bottom end of the test bench body 1 are fixed with universal wheels 2, and the top side of the test bench body 1 is A control panel 3 is fixedly installed, and a movable box 4 is movably installed on the other side of the top of the test bench body 1. The bottom end of the test bench body 1 is interspersed with a movable column 5, and a first spring 6 is wound outside the movable column 5. Two tool cabinets 7 are fixedly installed on the front of the test bench body 1, two first connecting frames 8 are fixedly installed on both sides of the inner wall of the test bench body 1, and a support block 13 is fixedly installed on the top of the movable column 5, and the support block 13 Two support plates 14 are fixedly installed on both sides of the two support plates 14, and a second rotating shaft ...

Embodiment 2

[0032] On the basis of Embodiment 1, such as Figure 4 , Figure 5 and Figure 6 As shown, two fixed plates 26 are fixedly installed on the front of the oil collecting tank 18, and the tops of the two fixed plates 26 are interspersed with fixed shafts 27, and one end of the two fixed shafts 27 is movably sleeved with a clamping plate 28. The top of the table body 1 is provided with two movable slots, and one side of the installation box 33 is provided with a plurality of tube slots 34, the inside of the two movable slots is slidably equipped with an auxiliary plate 29, and the outside of the two telescopic columns 16 is wound with Both sides of the second spring 17 and the oil collection tank 18 are provided with chute 19, and the tops of the two auxiliary plates 29 are hinged with an extension frame 30, and the tops of the two extension frames 30 are interspersed with magnets 31. The present invention provides chute 19, slide block 20, stop post 24, clamping plate 28, magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com